Understanding Mining Grid Technology and Its Geotechnical Function

Mining grids are engineered geosynthetic materials designed to stabilize soil and rock formations in underground construction. As three-dimensional reinforcement systems, they distribute structural loads laterally while mitigating shear stress-critical for applications like tunnel walls and mine shafts.

What Is a Mining Grid and How It Functions in Geotechnical Applications

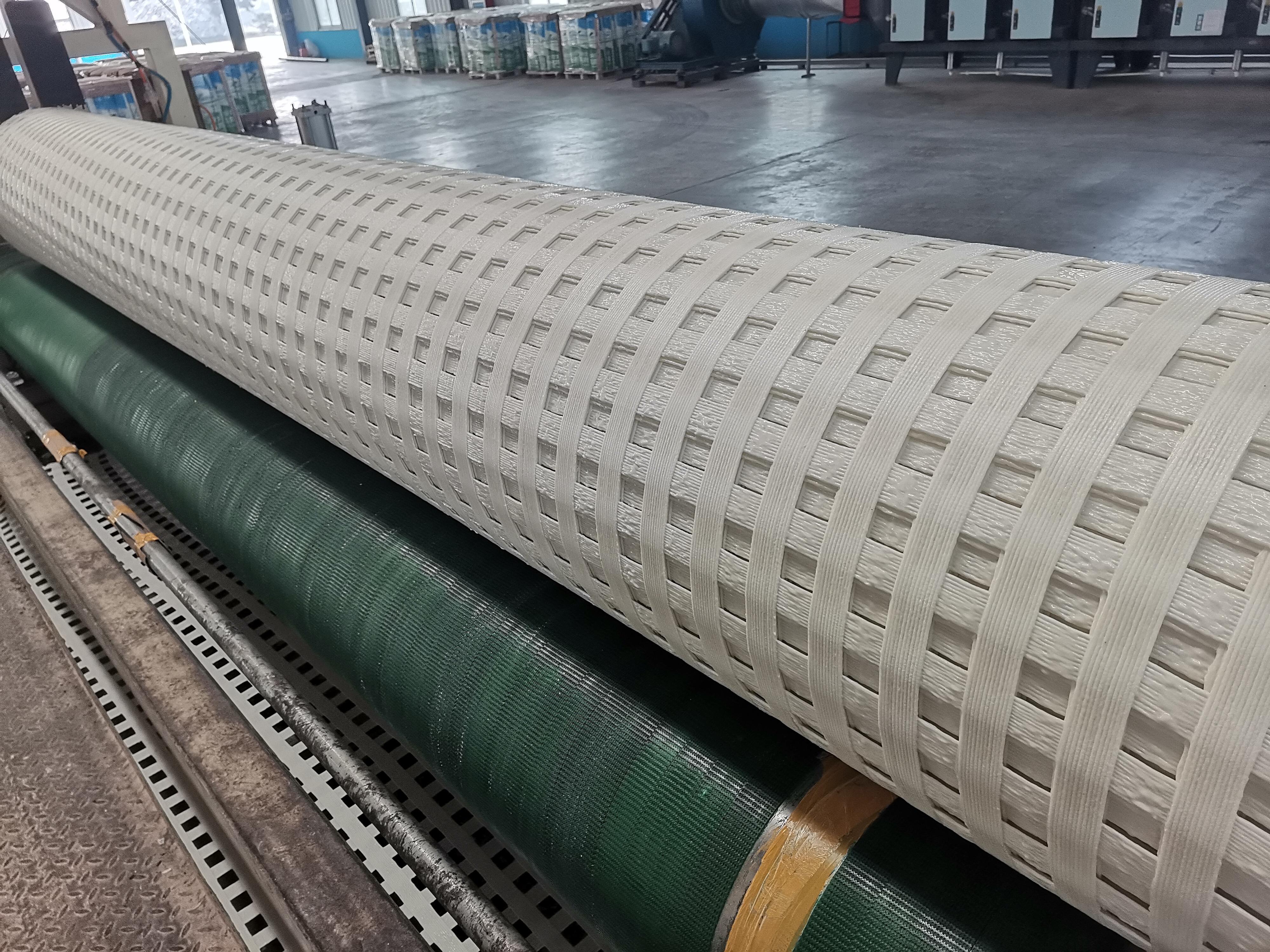

Modern mining grids are typically made from high-density polyethylene (HDPE) or steel alloys woven into modular panels. Their key functions include:

- Load redistribution: Reduces point stresses by up to 40% compared to unreinforced earth

- Shear resistance enhancement: Increases friction angles by 12-15° in fractured rock masses

- Drainage facilitation: Open structures allow controlled water flow, preventing hydrostatic pressure buildup

The Evolution of Mining Grid Technology in Underground Construction

From early timber lattices to today's polymer-based systems, mining grid technology has evolved to overcome persistent challenges: corrosion in acidic environments (pH <3), compatibility with mechanized tunneling, and long-term creep resistance under sustained loads (>50 MPa). Recent advancements include ultraviolet-stabilized polymers that retain 95% tensile strength after 25 years underground.

Key Properties of Mining Grid That Enhance Structural Integrity

Laboratory and field data highlight four critical performance characteristics:

| Property | Typical Range | Impact on Tunnel Stability |

|---|---|---|

| Tensile Strength | 50-200 kN/m | Resists roof collapse mechanisms |

| Junction Efficiency | ≥90% | Prevents unraveling under vibration |

| Aperture Size | 50-150 mm | Optimizes soil-grid interlock |

| Chemical Resistance | pH 1-14 stable | Extends service life in harsh mines |

These properties contribute to a 28% reduction in deformation rates compared to unreinforced sections, as observed in a 2023 study of shale-hosted tunnels.

Mining Grid for Temporary Tunnel Support: Mechanisms and Applications

Challenges in Maintaining Stability During Tunnel Excavation

Tunnel excavation triggers immediate stress redistribution, with 72% of construction delays linked to unplanned rock deformations or collapses. Mining grids help manage localized rock bursts in fault zones, control water ingress in porous strata, and compensate for geological survey inaccuracies that can underestimate fracture density by up to 40%.

Load Distribution and Stress Mitigation Using Mining Grid

These high tensile polymer grids can take on as much as 28 kN per square meter of radial stress by stretching in a controlled way, which helps push those forces away from the weak spots at the top of tunnels. Recent field tests back in 2024 found something pretty impressive happening in shale rock areas. When these grids got put in place just two hours after digging started, there was about a 63 percent drop in how fast cracks spread throughout the area. What makes them different from traditional steel supports is their ability to flex just enough. Mining grids typically have between 0.2 to 0.5 percent give or take, allowing them to handle normal ground movements without breaking down completely over time.

Integrating Mining Grid With Shotcrete and Rock Bolts for Optimal Temporary Support

Best-practice installations follow a sequential approach:

- Primary stabilization: Mining grids combined with rock bolts spaced at ≥1.2m intervals

- Secondary reinforcement: 50mm shotcrete layer embedding grid edges

This hybrid method achieved 98.7% stability during the critical 14-day curing period in soft-rock tunnels, outperforming traditional mesh systems, which reached only 82% stability.

Case Study: Application in a High-Risk Temporary Tunneling Environment

During the 2022 expansion of a coal access tunnel beneath water-saturated strata, contractors installed mining grids with 200 kN/m tensile strength every 0.8m. Results included:

- 40% faster installation than steel arch supports

- 30% cost reduction in temporary shoring over a six-month phase

- Zero safety incidents despite encountering three unforeseen fault lines

Post-project analysis confirmed deformation remained within ≥5mm thresholds, even with 12% higher groundwater pressure than initially estimated.

Mining Grid in Permanent Tunnel Reinforcement: Durability and Design

Long-Term Degradation Risks in Permanent Tunnel Linings

Permanent linings face cumulative degradation from groundwater infiltration, freeze-thaw cycles, and chemical corrosion. Unreinforced concrete in humid environments can lose 22% of its compressive strength within 15 years due to sulfate attack. Mining grids mitigate these risks by reducing crack propagation by up to 40%, as demonstrated in hydraulic tunnel simulations.

Enhancing Durability and Load Resistance with Mining Grid Over Time

High density polyethylene mining grids stand up really well against corrosion, holding onto about 95% of their original strength even after sitting in acidic mine water for quarter of a century. Tests conducted inside actual coal tunnels reveal something interesting too. When these grids have at least 80 kN/m tension strength, they cut down on structural deformation over time by around two thirds when compared to regular concrete linings without reinforcement. What makes them so tough is how they spread out pressure points where stress builds up naturally from underground movements or heavy machinery passing through regularly.

Design Considerations for Embedding Mining Grid in Permanent Concrete Linings

| Parameter | Optimal Range | Performance Impact |

|---|---|---|

| Grid spacing | 200-400 mm | Reduces crack width by 35-50% |

| Embedment depth | 1/3 lining thickness | Maximizes composite action with concrete |

| Joint overlap | ≥90 mm | Prevents stress concentration at seams |

These specifications prevent debonding and ensure compatibility with robotic shotcrete applicators.

Case Study: Reinforcement of Mine Vaults in Alpine Mining Operations Using Composite Geogrids

A European mining consortium deployed biaxial polypropylene geogrids in permanent access tunnels at 2,800m elevation. Over eight years, outcomes included:

- 64% reduction in ice-induced spalling damage

- 28% lower annual maintenance costs versus steel-reinforced linings

-

Zero structural failures despite temperature fluctuations down to -40°C

The grid's flexibility accommodated glacial movements and prevented water ingress through microcracks in shotcrete.

Comparative Advantages of Mining Grid vs. Traditional Reinforcement Methods

Deformation Control: Mining Grid Versus Steel Mesh - A Data-Driven Comparison

When it comes to controlling deformation, mining grids beat steel mesh hands down, cutting tunnel wall movement by around 42% when dealing with soft soils. Steel mesh is pretty rigid, but mining grids work differently. They spread tension through their polymer lattice structure which helps soak up those ground stresses. Looking at some recent data from 2022 that examined 14 different tunnels, we see something interesting happening. Sections reinforced with grids stayed within just under 3 mm displacement even under 25 MPa stress levels. Meanwhile, the steel mesh areas moved way more than that, going over 8 mm in similar conditions. What makes this really important? Well, in areas prone to earthquakes, steel tends to break suddenly. And guess what? About 37% of all tunnel collapses happen because of this kind of brittle steel failure. So for places with seismic activity, these flexible grids offer a much safer alternative.

Cost-Benefit Analysis Over 10-Year Installation and Maintenance Cycles

Although mining grids have an 18% higher initial material cost than steel mesh, their 10-year lifecycle costs are 28% lower based on a longitudinal review of 23 mining projects. Key savings arise from:

- 55% reduction in labor hours due to modular design versus manual welding

- 92% fewer corrosion-related repairs thanks to polymer durability

- 40% longer maintenance intervals

Traditional methods incur hidden costs from auxiliary support needs and schedule delays caused by reinforcement failures.

Is Mining Grid Underutilized Despite Superior Performance? Industry Insights

Despite demonstrating 31% higher load capacity in ASTM tests, mining grids are used in only 22% of North American tunneling projects. This underuse reflects three main barriers:

- Legacy Specifications: 67% of public infrastructure contracts still require steel reinforcement

- Training Gaps: Only 38% of contractors possess polymer grid installation equipment

- Perception Lag: 55% of engineers overestimate mining grid costs by 200-300%

Recent ISO 9001-certified manufacturing improvements have resolved early concerns about UV stability and anchor compatibility, paving the way for broader adoption in critical infrastructure.

Innovations in Mining Grid Materials for Future Tunnel Safety

High-Tenacity Polymer-Based Grids for Corrosive Underground Environments

The latest polymer composites stand up against extreme pH levels and saltwater corrosion for about 2.3 times longer than regular galvanized steel when put through those accelerated aging tests. What makes these grids so durable? They mix PET fibers with special anti-microbial coatings that really cut down on breakdown from acidic mine water runoff. Looking at some recent testing from 2023, these new materials kept 87% of their original strength even after sitting in damp underground tunnels for five whole years. Traditional welded mesh only managed around 63% strength retention under similar conditions, which shows just how much better these composites perform over time.

Smart Mining Grids With Embedded Sensors for Real-Time Structural Monitoring

Fiber optic sensors built into grid structures can pick up strains as tiny as 0.02%, making them about fifteen times more sensitive compared to traditional manual checks. Combine these advanced sensors with predictive analysis tools and maintenance teams see a reduction of around 40% in unexpected repairs. The system spots potential problem spots long before any actual damage becomes visible to the naked eye. For regions prone to earthquakes or other seismic activity where the ground might shift more than five millimeters each year, this kind of early detection really makes all the difference. Knowing what's happening underground helps prevent major failures down the road.

Balancing Cost Efficiency With Advanced Material Innovation in Mining Grid Production

Three innovations drive cost-effective production:

- Modular design enabling 22% faster installation than custom-cut steel grids

- Recycled material integration achieving 45% composite content without sacrificing yield strength

- Hybrid manufacturing techniques combining extrusion and robotic welding to cut energy use by 18 kWh per ton

Lifecycle analyses confirm these advances deliver 19% lower total ownership costs over a 10-year tunnel service period compared to conventional methods.

FAQ

What materials are mining grids made of?

Mining grids are typically made from high-density polyethylene (HDPE) or steel alloys woven into modular panels.

How do mining grids contribute to tunnel stability?

Mining grids help reduce point stresses, increase friction angles in fractured rock masses, and facilitate drainage, ultimately enhancing tunnel stability.

What are the benefits of using mining grids over traditional reinforcement methods?

Mining grids offer superior deformation control compared to steel mesh, reduce installation labor hours, minimize corrosion repairs, and extend maintenance intervals.

Are mining grids suitable for both temporary and permanent tunnel support?

Yes, mining grids are applicable for both temporary and permanent tunnel reinforcement, offering durability and load resistance by reducing crack propagation and pressure points.

What innovations are driving the future of mining grids?

Innovations include high-tenacity polymer-based grids resistant to corrosive environments, smart sensor-embedded grids for structural monitoring, and cost-efficient modular designs.

Table of Contents

- Understanding Mining Grid Technology and Its Geotechnical Function

- Mining Grid for Temporary Tunnel Support: Mechanisms and Applications

- Mining Grid in Permanent Tunnel Reinforcement: Durability and Design

- Comparative Advantages of Mining Grid vs. Traditional Reinforcement Methods

- Deformation Control: Mining Grid Versus Steel Mesh - A Data-Driven Comparison

- Cost-Benefit Analysis Over 10-Year Installation and Maintenance Cycles

- Is Mining Grid Underutilized Despite Superior Performance? Industry Insights

- Innovations in Mining Grid Materials for Future Tunnel Safety

-

FAQ

- What materials are mining grids made of?

- How do mining grids contribute to tunnel stability?

- What are the benefits of using mining grids over traditional reinforcement methods?

- Are mining grids suitable for both temporary and permanent tunnel support?

- What innovations are driving the future of mining grids?