Foundations of Slope Stability and the Safety Factor

When we talk about slope stability, we're basically looking at how well a slope can hold together against all those forces pulling it apart, including gravity and weather effects. Engineers measure this using something called the Factor of Safety (FS), which compares what's holding the slope up (like soil strength and friction between particles) versus what's trying to make it collapse (mainly shear stress). A number above 1 means theoretically stable, but when dealing with important structures like bridge supports, most experts shoot for at least 1.5 because nobody wants to deal with catastrophic failures. There are different ways to calculate these factors. One common approach breaks slopes down into vertical sections to check if everything balances out, while another method called finite element modeling gives better pictures of how stresses actually move through the ground. Still, neither technique is perfect. Deterministic calculations tend to be overly optimistic sometimes, maybe even off by 30% or so in soils that have layers of varying strength. That's where probabilistic methods come in handy, running thousands of scenarios with different soil properties to account for uncertainties. What counts as acceptable safety varies depending on several factors: how reliable our testing was, how confident we feel about the soil data, and what happens if things go wrong. For regular road embankments, 1.25 is usually good enough, but bump that up to around 1.5 when working near sensitive areas.

How Geogrid Reinforcement Enhances Slope Stabilization

Tensile Resistance and Load Redistribution Across Weak Layers

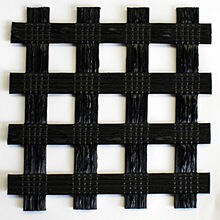

When geogrids are added to slopes, they actually change how these slopes behave because they bring in controlled tensile strength within the soil system itself. Traditional unreinforced slopes tend to have all their stress concentrated along those initial failure planes, but when we install geogrids, they spread out the load sideways through weaker or wetter parts of the ground. What happens here is pretty interesting - this bridging effect cuts down on localized shear stress somewhere around 40% in many cases, which stops those little failures from spreading throughout mixed soils or areas affected by groundwater. Looking at it another way, the grid has this open structure that functions kind of like a skeleton frame, moving gravitational forces away from spots with poor strength towards stronger layers underneath where things can hold better.

Soil-Geogrid Interface Friction and Shear Strength Mobilization

The effectiveness of stabilization really hinges on how well the soil interacts with the geogrid surface. When tiny soil grains fit into the openings of these grids, it actually increases shear resistance quite a bit. We're talking about a boost in cohesive strength ranging from around 25% up to maybe 60% in those granular soils. What happens here is pretty interesting - the geogrid takes care of stretching forces while the surrounding soil handles compression stresses. Getting good results means matching three things properly: where the grid connections are strongest, the shape of the grid openings, and what kind of soil particles we're dealing with. This ensures everything works together when there's shaking from earthquakes or heavy rains pounding down.

Quantifying Safety Factor Gains from Geogrid Implementation

Empirical Evidence: Average Safety Factor Increase from 1.15 to 1.6 Across 15 Projects

Looking at data from 15 different field projects reveals that using geogrid reinforcement tends to boost safety factors (SF) across the board. Before installing these reinforcements, the average SF was around 1.15, which sits pretty close to what's considered unstable. After adding the geogrids, we saw the average jump up to 1.6. That represents nearly a 40% improvement mainly because the reinforcement spreads out tension better and increases friction between surfaces. What's really interesting though? Out of those 15 projects, 13 maintained an SF above 1.5 even after facing severe weather conditions. This suggests that these reinforced structures can hold up well over time when subjected to changing loads and environmental stresses.

Design Optimization for Maximum Slope Stabilization Efficiency

Peak FS gains require deliberate design choices:

- Material specification: High-stiffness geogrids (>500 kN/m tensile strength) improve FS by 25% over lower-strength alternatives in cohesive soils

- Interface optimization: Matching aperture size to soil gradation increases shear resistance by 30%

- Placement depth: Embedding grids at 0.3H–0.5H slope height maximizes confinement pressure and lateral restraint

When implemented correctly, optimized geogrid systems reduce construction costs by 22% versus conventional methods and extend service life beyond 50 years. Computational modeling confirms such designs achieve FS > 1.8 in 90% of high-risk slopes.

Best Practices for Geogrid Selection and Installation in Slope Stabilization

Getting slope stabilization right starts with really understanding what's going on at the site. Soil shear parameters matter a lot, along with how groundwater behaves and the actual shape of the slope itself when choosing geogrids. The tensile strength needs to match up with the soil type being worked with. Cohesive soils generally need something that can handle higher friction between surfaces, while granular fill materials actually work better with bigger openings in the geogrids since they lock together mechanically. When it comes time to install these systems, first thing is clearing away all the plants and junk from the area. Then properly grading those slopes according to their intended angles becomes critical too. Don't forget about putting in proper drainage systems during this process either, because controlling water buildup underneath is absolutely essential for long term stability.

When laying out geogrids, start at the bottom and work upwards, making sure there's an overlap between 6 to 12 inches on each section. Secure the edges properly with staples that won't corrode over time or bury them in trenches as needed. The backfill process should be done in layers about 6 to 8 inches thick, and each layer needs to reach at least 95% of the standard Proctor density. If the compaction varies too much (more than plus or minus 10%), the whole reinforcement system becomes about 30% less effective. Keeping track of things like proper alignment, tension levels, intact seams, and even compaction throughout the project is absolutely critical. Field tests show that when teams stick strictly to these guidelines, they end up with around 25% fewer problems down the road. This kind of careful attention makes all the difference when working through challenging soil conditions where stability matters most.

FAQ

What is the Factor of Safety in slope stabilization?

The Factor of Safety (FS) is a measure used to determine the stability of a slope by comparing the forces resisting a slope's collapse (such as soil strength) against the forces trying to pull it apart (such as shear stress).

How does geogrid reinforcement improve slope stability?

Geogrid reinforcement enhances slope stability by redistributing tensile forces and increasing soil friction, thereby reducing shear stress concentrations and increasing the overall strength of the soil structure.

What are the benefits of using geogrid systems in slope stabilization?

Geogrid systems offer numerous benefits, including improved safety factors, reduced localized stress failures, lower construction costs, and extended service life of slopes.

How should geogrids be installed for optimal effectiveness?

Geogrids should be installed from the bottom up, with overlapping sections secured properly. The area should be cleared of vegetation, properly graded, and fitted with drainage systems to ensure long-term stability.