Superior Directional Reinforcement: How Uniaxial Geogrid Delivers High Tensile Strength Where It's Needed Most

Polymer Alignment and Rib-Node Architecture Enable Anisotropic Strength

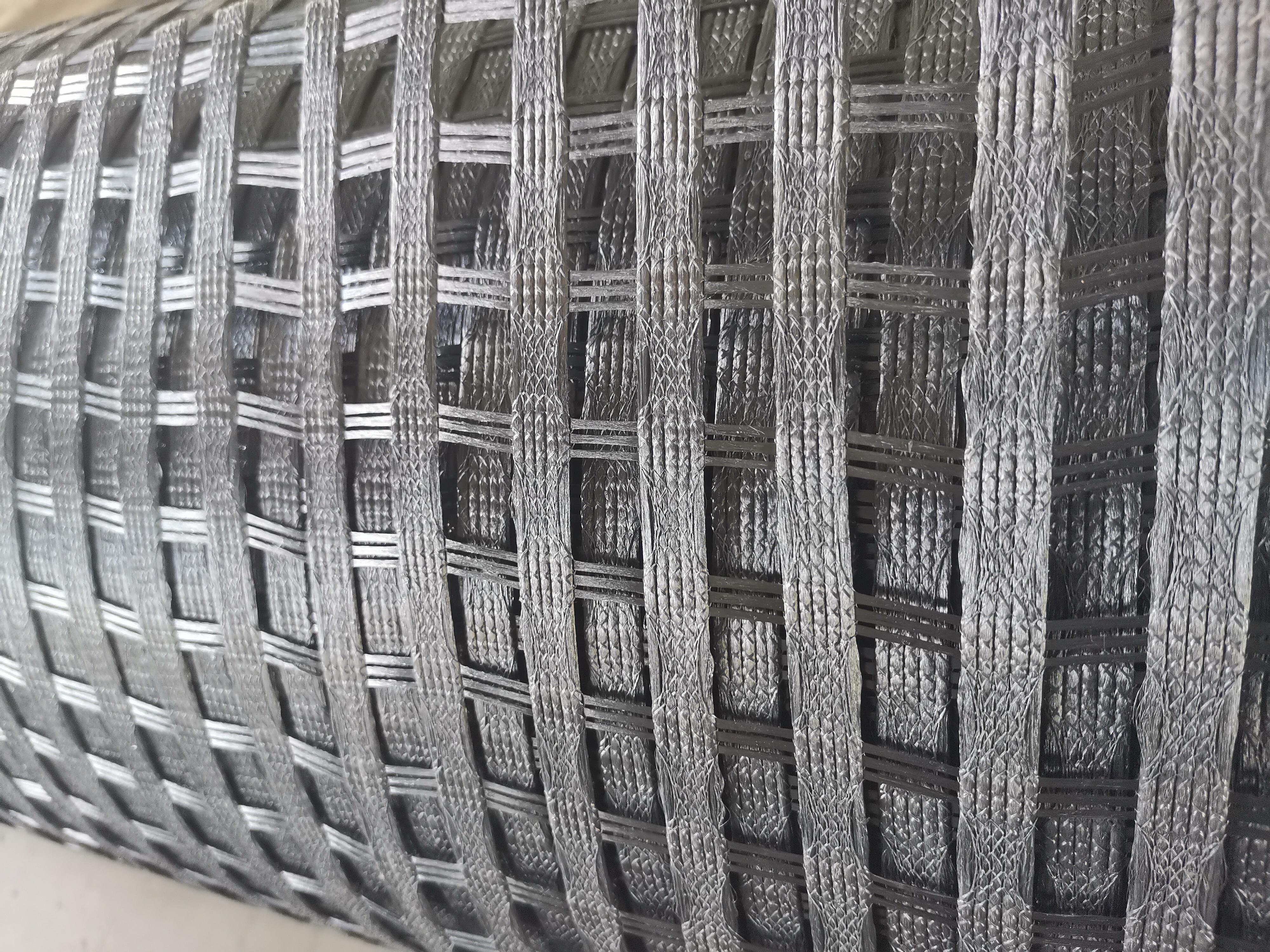

The way uniaxial geogrids work their magic lies in how they're made at the molecular level. During production, manufacturers stretch out extruded polymer sheets along one direction, which lines up all those polymer molecules like soldiers standing at attention. This creates some serious tensile strength numbers - we're talking around 20 to 400 kN/m according to ASTM D6637 standards - but only along that single stretching direction. What makes these grids so effective is this focused approach paired with their strong rib and node connections. The result? Strength isn't spread evenly everywhere but instead packed right where the soil needs it most under pressure. Those elliptical holes aren't just decorative either; they actually grip onto surrounding aggregates better, transferring loads efficiently without letting things deform too much. Compared to materials that distribute strength equally in all directions, this design smartly puts resources exactly where they matter most for both structural integrity and cost effectiveness on actual construction sites.

42% Higher Pullout Resistance vs. Biaxial Grids in Sand Backfill (FHWA-HRT-17-065)

Tests by the Federal Highway Administration show that uniaxial geogrids offer about 42% better pullout resistance compared to biaxial grids when both have similar tensile strength in sand backfill environments [FHWA-HRT-17-065]. Why does this happen? Well, these grids feature longer ribs running one direction which creates more contact points with the surrounding soil particles. When loaded, this increased surface area generates stronger friction between the grid and the soil. What does all this mean practically? Greater stability where the grid anchors into the ground. Contractors can install these systems at shallower depths, use less material overall, and complete installations quicker for things like retaining walls or slope stabilization projects. And importantly, they still maintain good resistance against sideways forces from the earth.

Enhanced Structural Stability in Retaining Walls and Slopes with Uniaxial Geogrid

Confinement Mechanism: Reducing Lateral Earth Pressure Through Soil Interlock

The uniaxial geogrid works by creating a sort of mechanical grip between its long ribs and the aggregate around it. When these ribs dig into the backfill material, they basically create a solid mass that holds everything together, stopping both side to side and up down movements in the soil. What happens next is pretty interesting the pressure that normally builds up against walls and slopes gets spread out differently, which helps prevent problems like bulges, slides, and overall structural failure. Since most of the strength comes from tension along the main direction where stress occurs, this grid system fights against those shearing forces especially well in areas with steep grades or heavy loads.

30–50% Reduction in Required Wall Face Thickness (NCMA Design Guidelines, 2022)

When using uniaxial geogrids, engineers can actually design much thinner concrete or masonry walls for retaining structures. We're talking reductions of around 30 to 50 percent thickness while still meeting all the safety requirements set out in the latest NCMA guidelines. What makes this possible? The geogrid transfers loads effectively into the surrounding soil, so there's less need for those heavy duty structural components. This approach cuts down on materials needed for the job, speeds up construction timeframes, and maintains slope stability over the long haul. Whether working on homes, office buildings, or major infrastructure projects, these benefits translate directly into cost savings and better performance throughout the lifespan of the structure.

Cost and Time Efficiency: Streamlining Construction with Uniaxial Geogrid

Optimized Layer Spacing and Thinner Sections Cut Material and Labor Costs

The use of uniaxial geogrid allows engineers to design structures that are actually thinner with greater spacing between layers, all while maintaining their strength characteristics. This means construction sites need about a quarter to half as much aggregate material and backfill compared to traditional approaches. The reduced material requirements naturally lead to shallower excavations, less soil needing replacement, and significant cuts in both hauling and waste disposal expenses. Machines run for shorter periods, burning less fuel overall. Workers also find the process smoother too. According to several on-site tests, installing these grids takes around 30 percent less time than older reinforcement techniques because they're easier to handle, align properly, and position correctly in the ground. When looking at big infrastructure jobs like highway expansions or building new embankments, these kinds of improvements really make a difference. Contractors report finishing projects weeks ahead of schedule and seeing noticeable reductions in overall project budgets when using this technology.

HDPE vs. Polyester: Balancing Installation Speed and Long-Term Creep Performance

The high density polyethylene (HDPE) uniaxial geogrid has some real benefits when it comes to how fast it can be deployed. Because it's so flexible and lightweight, construction crews can actually cover about 40 percent more ground during each work shift than they would with stiffer materials. On the flip side, polyester (PET) stands out for its excellent long term creep resistance, which matters a lot for things like bridge abutments and dam foundations where stability is crucial. Tests show PET deforms roughly 60 percent less over time when subjected to constant loads. HDPE definitely speeds things up during initial construction phases, but PET's reduced strain after construction means there will be far fewer maintenance issues down the road. When engineers pick between these options, they look at both the expected lifespan of the project and what kind of performance they need most. For transportation projects where getting things done quickly is top priority, HDPE tends to win out. But for those really important earthworks that need to last decades or even centuries, PET gets specified despite taking just a little bit longer to install properly.

FAQ Section

What is uniaxial geogrid commonly used for?

Uniaxial geogrid is often used to reinforce retaining walls, slopes, and embankments. Its design optimizes tensile strength in a single direction, providing superior reinforcement in specific areas.

How does uniaxial geogrid differ from biaxial geogrids?

Uniaxial geogrids have higher pullout resistance compared to biaxial grids due to their single-directional design, which allows for greater rib-soil contact points and enhanced friction between the materials.

Can uniaxial geogrid be used for both horizontal and vertical reinforcement?

Yes, uniaxial geogrids can be used for both horizontal and vertical applications, providing enhanced structural stability in retaining walls and slopes by effectively reducing lateral earth pressure.

What factors determine whether HDPE or PET should be used in a project?

The choice between HDPE and PET depends on installation speed and long-term performance needs. HDPE is favored for its flexibility and quicker deployment, while PET is preferred for its excellent long-term creep resistance.

Table of Contents

- Superior Directional Reinforcement: How Uniaxial Geogrid Delivers High Tensile Strength Where It's Needed Most

- Enhanced Structural Stability in Retaining Walls and Slopes with Uniaxial Geogrid

-

Cost and Time Efficiency: Streamlining Construction with Uniaxial Geogrid

- Optimized Layer Spacing and Thinner Sections Cut Material and Labor Costs

- HDPE vs. Polyester: Balancing Installation Speed and Long-Term Creep Performance

- FAQ Section

- What is uniaxial geogrid commonly used for?

- How does uniaxial geogrid differ from biaxial geogrids?

- Can uniaxial geogrid be used for both horizontal and vertical reinforcement?

- What factors determine whether HDPE or PET should be used in a project?