Mechanical Resilience: Withstanding Freeze-Thaw Cycles and High Groundwater Pressure

Fatigue Resistance Under Repeated Freeze-Thaw Exposure

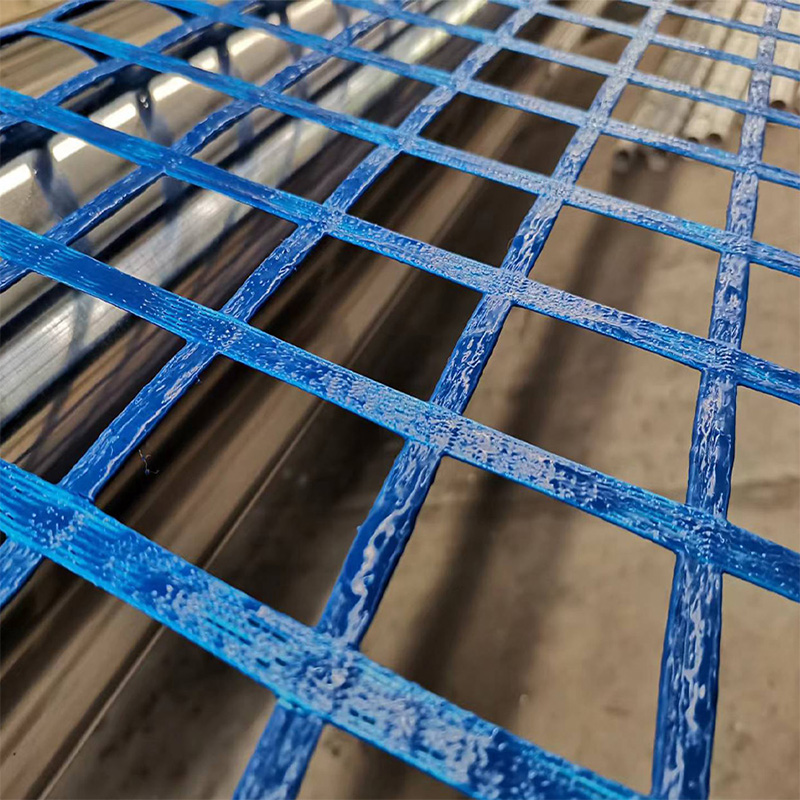

Mine grid materials made from polymers really hold up well when subjected to those constant freeze-thaw cycles that plague many mining operations. Tests have confirmed that these materials deform by less than 1% after going through around 300 cycles, which beats what we typically see with older geosynthetic products. Why does this happen? Well, it turns out the special crystalline structure in these advanced polymers actually stops tiny fractures from spreading, even down at temperatures as low as minus 40 degrees Celsius. These polymer grids still keep about 98% of their original strength too. Looking at recent research, only three papers in last year's Geocomposite Durability Meta-Analysis focused specifically on how materials handle freeze-thaw conditions. That small number highlights why this property matters so much for projects in colder regions or deeper underground mines where temperature fluctuations are extreme.

Hydrostatic Load Performance at >500 kPa Groundwater Pressure

Mine grids can handle groundwater pressures well above 500 kPa (about 72.5 psi), which is really important for stopping soil from turning to slurry when floods hit active or old mining sites. Tests show that even after being subjected to constant pressure of around 550 kPa (think of it as the weight of water 55 meters high), these grids only deform by less than 0.2%. The reason they hold up so well comes down to their design features. The ribs are arranged in a way that locks together, while the materials used have just the right density. This setup spreads out the water pressure across the whole grid instead of letting all the force build up at weak points where components meet.

Chemical Durability: Mine Grid Performance in Acidic and Corrosive Conditions

pH Stability Range (1–14) for Polymer-Based Mine Grid

Mine grids made from polymers stay strong throughout all sorts of pH conditions, whether dealing with super acidic leachate pools around pH 2 or the alkaline areas where processing happens at about pH 12. After running tests for a whole year, there was basically zero drop in tensile strength or changes to how stretchy they remain compared to metal options which start breaking down when pH drops below 4 or goes over 10. These special polymer structures don't react much to those protonation and deprotonation processes that typically wear down regular materials through ion exchange. For companies handling waste streams that swing between different pH levels, this kind of stability means fewer breakdowns caused by corrosion and saves them somewhere between 40% to 60% on fixing problems down the road. Mines and processing plants especially benefit from these properties since their environments are constantly changing chemically.

Long-Term Sulfuric Acid Immersion: Tensile Retention After 5,000 Hours

Premium polymer mine grids maintain impressive durability even when submerged constantly in 30% sulfuric acid, which serves as a good stand-in for the harsh conditions found in acid mine drainage. After spending around 208 days (that's 5,000 hours) in this environment, these grids still hold onto more than 85% of their initial tensile strength. Tests conducted at accelerated aging temperatures of 60°C show minimal degradation too - less than 3% mass loss overall, absolutely no signs of surface cracks or becoming brittle, and the load continues to transfer properly between all the grid connections. What makes this really stand out is how much better it performs compared to what's required by ASTM F2456 standards; we're talking about doubling the specifications here. For permanent installations in areas where acids are naturally produced, especially places with pH levels below 1.5 where traditional steel reinforcement bars usually start failing within just 18 months because they corrode so fast and lose their grip on surrounding materials, these polymer grids offer a far more reliable solution.

Long-Term Structural Integrity: Creep, Aging, and Design-Life Validation for Permanent Mine Grid Installations

Creep Strain Accumulation Beyond 20-Year Service Life

Mine grids made from HDPE show very little creep when subjected to constant loads over time. Independent research stretching back decades shows these materials retain over 80% of their original tensile strength even after sitting underground for two full decades. When we look at what happens at around 30% of the maximum load capacity, which is pretty standard as a safety buffer in most designs, the strain buildup stays under 3%. That's way below the levels where any real problems would start occurring. The results have been checked against accelerated aging tests that mimic what happens over 25 years of actual underground conditions including all sorts of pressures from the earth itself, temperature changes going up and down, plus constant moisture exposure.

Bridging the Gap: Why ASTM D6758 Underestimates Real-World Mine Grid Degradation

The ASTM D6758 standard offers some basic guidelines for testing geosynthetics, though it falls short in real world mining conditions where multiple factors interact. Lab tests don't account for temperature changes caused by freezing and thawing cycles, miss out on how materials react to acidic substances found in leachates (around pH 2 to 4 range), and completely ignore wear and tear from blasting vibrations. Real field data keeps showing degradation happens about 40% faster than what these lab tests predict. When dealing with long term installations, extra testing at actual sites becomes necessary. This should include looking at repeated water pressure effects, biological growth impacts, and how materials age under combined stresses rather than relying solely on standard lab results.

FAQ Section

What are the advantages of polymer-based mine grids?

Polymer-based mine grids offer outstanding mechanical resilience, chemical durability, and long-term structural integrity. They maintain strength under extreme freeze-thaw cycles, high groundwater pressure, and acidic conditions, making them ideal for challenging mining environments.

How do polymer materials compare to metal options?

Polymer materials outperform metal options by maintaining tensile strength and structural integrity under a wide range of pH conditions. Metals tend to break down when pH levels are too low or high, whereas polymers do not react as strongly to ion exchange processes.

What happens when mine grids are submerged in sulfuric acid?

Premium polymer mine grids show impressive durability when submerged in sulfuric acid for extensive periods, retaining more than 85% of their initial tensile strength even after 5,000 hours in such conditions.

Why is real-world testing important for mine grids?

Real-world testing is crucial because lab standards like ASTM D6758 often underestimate degradation factors such as temperature changes, acidic reactions, and mechanical wear. Field tests provide more accurate data for long-term mine grid installations.