PET Geogrid Material Superiority for Long-Term Performance

UV, Hydrolysis, and Chemical Resistance in Harsh Environments

PET geogrid stands out when it comes to resisting things like ultraviolet light, water breakdown, and chemicals that would normally wear materials down over time. The reason? Its special polyester structure doesn't break apart when exposed to sunlight. Tests show that PET loses about 30% less strength compared to other common materials like polypropylene or HDPE when subjected to harsh weather conditions according to standard test methods. Even when submerged for long periods, PET keeps most of its strength intact, maintaining over 85% of original tensile strength while showing less than 15% degradation from water damage. What makes this material really useful is how it handles extreme chemical environments. It works well across a wide pH range from 2 to 12, which means it can be used in tough places like industrial waste containment areas or along coastlines where saltwater corrosion is a problem. Because of all these properties, engineers have seen PET last more than 50 years in important projects such as covering landfills and stabilizing slopes. When materials fail prematurely in these situations, entire systems can collapse, so choosing durable options matters a lot for long term success.

Exceptional Creep Resistance and Tensile Retention Under Sustained Loads

PET geogrid holds up really well when subjected to long term loads, showing less than 5% strain even after many decades. This makes it way better than PP based options that tend to deform around 15-20% under similar conditions. The material's semi crystalline structure helps prevent molecules from slipping past each other, so it retains about 90% of its original strength after roughly 10,000 hours of constant stress according to ASTM D5262 tests. Such strong resistance to creep means less settling occurs in structures like retaining walls and at bridge connections where different parts moving at different rates could weaken everything. Real world observations on roads built with PET reinforcement have shown these areas deform only one third as much compared to regular slopes without any reinforcement after 15 years. This consistency in how weight gets distributed saves money because there's no need for expensive fixes later on in both road building and mining operations.

Mechanisms of Soil Reinforcement and Load Distribution

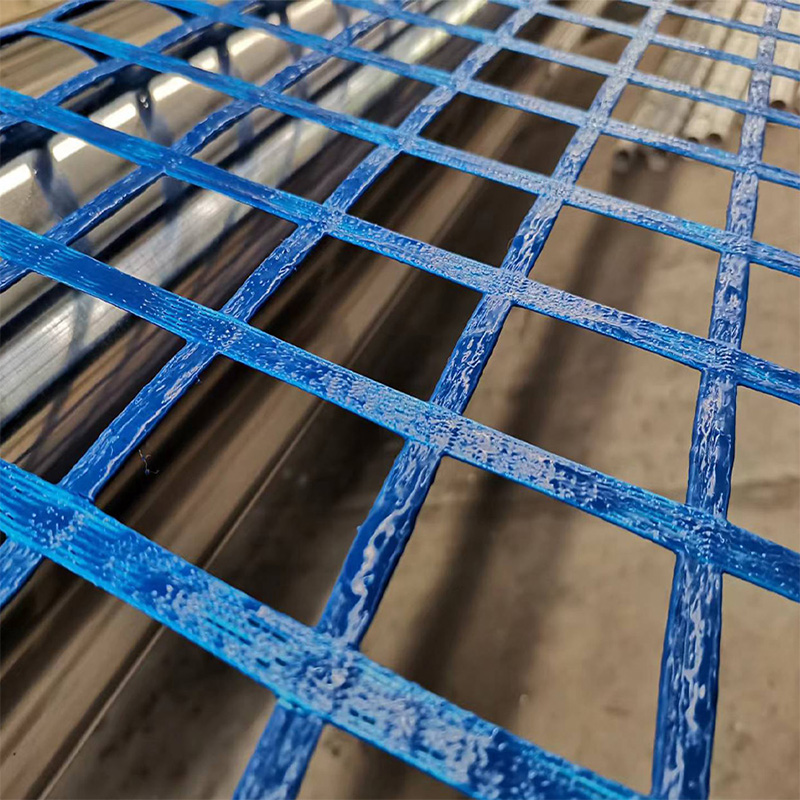

Interfacial Bonding and Stress Redistribution via PET Geogrid Apertures

PET geogrid works by mechanically locking into the soil structure. When compacted, both granular and cohesive soil particles get wedged into the grid's openings, creating what engineers call a composite mass. What happens next is pretty interesting - these interactions spread out vertical pressure across the ground surface, cutting down on those pesky hotspots where pressure builds up too much. Tests show this can reduce point pressures by around 40% compared to regular soil without reinforcement according to US DOT research from 2022. Another great thing about PET grids is their open design. Not only does it let roots grow through naturally, but water drains better too. Plus they hold up surprisingly well under tension forces, typically above 50 kN per meter, which stops those annoying shear failures we all hate. For construction projects working with poor quality fill material, adding PET geogrid turns marginal land into something solid enough to support roads, buildings, and other heavy infrastructure without worrying about sinking or shifting over time.

Mitigation of Settlement, Erosion, and Differential Movement in Embankments

By confining soil particles and dissipating stress across a wide zone, PET geogrid reinforcement effectively addresses three primary embankment risks:

- Settlement reduction: Uniform load distribution decreases consolidation settlement by 60–80% in cohesive soils

- Erosion control: The stabilized soil-grid matrix resists particle migration even on steep 1:1 slopes

- Differential movement prevention: Continuous tensile strength absorbs dynamic energy from traffic or seismic events, preserving alignment

Long-term field data from reinforced earth walls show 5 mm total displacement after 10 years–outperforming conventional solutions by a factor of three.

Real-World Validation of PET Geogrid Longevity in Critical Infrastructure

15+ Year Field Performance: Reinforced Retaining Walls (US DOT Data)

The US Department of Transportation has been keeping an eye on PET geogrid reinforced retaining walls and what they've found is pretty impressive. These structures keep performing well even after 15 years or more, despite being exposed to tough weather and chemical environments. Tests show that about 80 percent or so of their original tensile strength stays intact, which matches what labs predicted regarding how resistant they are to breaking down from water exposure. Maintenance costs drop by around 35% compared to regular unreinforced walls, saving highway departments roughly $740k per mile over two decades according to recent Federal Highway Administration data from 2023. What makes this technology stand out is its grid pattern that actually locks into the surrounding soil really well. This feature allows the walls to hold up during earthquakes where ground shaking reaches up to half gravity force without collapsing completely.

Pavement Life Extension: Reduced Rutting and Reflective Cracking in PET-Reinforced Asphalt

Putting PET geogrid material between asphalt layers cuts down on rutting by about 60 percent and pretty much stops reflective cracking at around 90% compared to regular pavements without any reinforcement according to TRB research from last year. What happens is that these grids spread out the weight from vehicle wheels over areas where the ground underneath isn't so stable or changes in quality. This kind of support makes roads last longer too, somewhere between eight to twelve extra years before needing major work. And because there's less damage happening over time, the money spent fixing things throughout the road's entire lifespan drops by roughly 45%. That's really important stuff for busy highways that see more than ten million equivalent single axle loads each year, which basically means they handle massive traffic volumes day after day.

PET Geogrid vs. Alternative Geosynthetics: A Longevity-Focused Comparison

When evaluating geosynthetic solutions for soil stabilization, longevity directly influences lifecycle cost and structural reliability. PET geogrid consistently outperforms common alternatives–including PP/HDPE, fiberglass, and steel-plastic composites–in durability-critical metrics:

| Material | Tensile Strength (kN/m) | Creep Resistance | UV Resistance (% retention) | Chemical Resistance (pH range) | Expected Lifespan |

|---|---|---|---|---|---|

| PET Geogrid | 50–500 | Exceptional | 85–95% | 2–12 | 50+ years |

| PP/HDPE Geogrid | 20–200 | Moderate | 80–90% | 2–12 | 30–50 years |

| Fiberglass | 50–400 | Low | 70–85% | 3–11 | 20–30 years |

| Steel-Plastic | 50–600 | High | 80–90% | 2–12 | 50+ years |

The molecular makeup of PET gives it much better resistance against stress relaxation than PP does, which means it deforms about 30 to maybe even 40 percent less over time. Steel plastic composites can last just as long as PET materials, but they weigh way more around 500 grams per square meter up to 1000 grams and typically cost somewhere between 30 and 50 percent extra, making them impractical for most projects. Fiberglass tends to break down pretty quickly when exposed to alkaline soil conditions, while PP HDPE grids start showing signs of creep when temperatures rise. When looking at infrastructure that needs to stand up for decades or even centuries, PET geogrid stands out because it combines good tensile strength over time with decent environmental durability without breaking the bank in the long run.

Frequently Asked Questions

- What is PET geogrid? PET geogrid is a type of geosynthetic material made from polyester that is used for soil stabilization and reinforcement in construction projects.

- How does PET geogrid compare to other materials? PET geogrid offers superior UV resistance, hydrolysis resistance, and chemical resistance, making it more durable than typical materials like polypropylene, HDPE, fiberglass, and steel-plastic composites in harsh environments.

- What are the benefits of using PET geogrid in construction projects? Using PET geogrid helps reduce settlement, control erosion, and prevent differential movement in embankments, leading to longer-lasting structures and reduced maintenance costs.

- How long does PET geogrid last? PET geogrid can last over 50 years, making it a reliable choice for long-term performance in critical infrastructure projects.