Understanding Geogrid Road Construction

What Is Geogrid and How Does It Work?

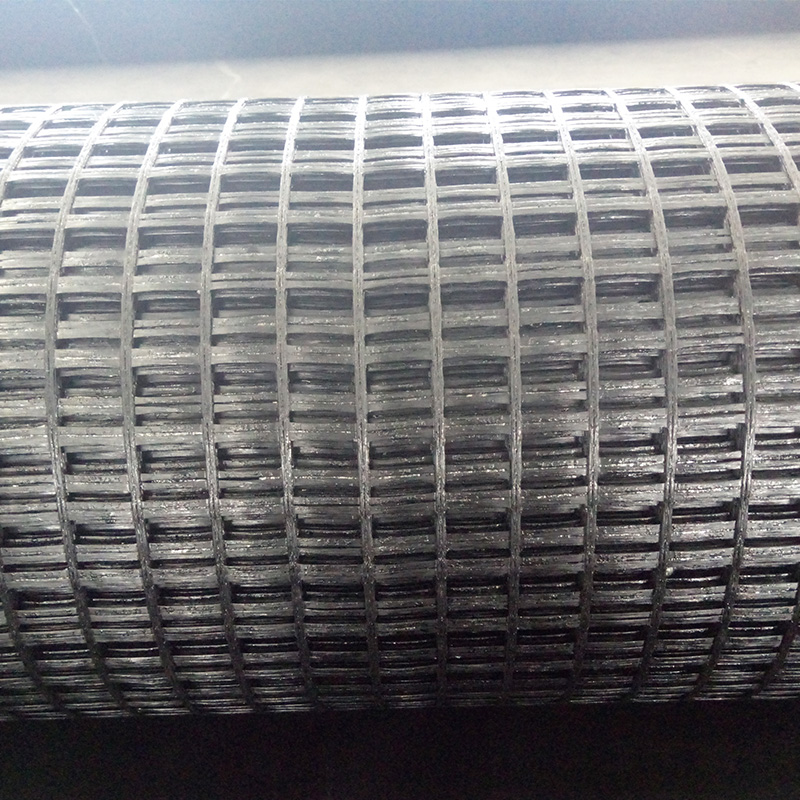

Geogrids are synthetic materials commonly used in civil engineering to stabilize soil, especially when building roads. They work by locking together soil particles, spreading weight more evenly throughout the ground and reducing how much the earth settles over time. The market offers different kinds of geogrids: uniaxial, biaxial, and triaxial. These aren't just random names but actually reflect their performance characteristics. Uniaxial grids do great job holding up soil walls, whereas biaxial versions can handle stress from all directions, so they're often seen under road surfaces. For really tough jobs where maximum support matters, engineers turn to triaxial geogrids that give extra reinforcement to keep road constructions intact. When soil gains more tensile strength through these grids, roads last longer without cracking or sinking, which saves money on repairs down the line for municipalities and contractors alike.

Key Advantages of Geogrid Reinforcement

Using geogrid reinforcement in road building brings several real benefits. Roads become much stronger under heavy traffic because they resist deformation better. This strength means contractors spend less money on materials since they don't need as much aggregate or other construction stuff. Research indicates that roads built with geogrids last about half again as long as those made the old way, which speaks volumes about how good these reinforcements actually are. From an environmental standpoint, geogrids cut down on traditional materials needed for construction work, which naturally lowers carbon footprints and saves resources overall. Road builders who adopt this tech see improved efficiency while staying ahead of the curve in sustainable infrastructure trends worldwide.

Challenges of Road Construction in Cold Regions

Temperature Extremes and Ground Instability

Building roads in cold areas presents unique difficulties because of the wild temperature swings that happen there. When temperatures drop dramatically at night and rise during the day, the ground itself becomes unstable. This back and forth causes problems like soil heaving where frozen ground expands and then thaws out again. Frost penetration is another big issue for road builders. The depth to which frost goes into the ground varies quite a bit from place to place, and this variation puts real stress on the base layer beneath roads. The Federal Highway Administration suggests several ways to handle these issues, including the use of strong materials such as geogrids. These special grids work by locking together soil particles below the road surface, creating a stronger foundation that spreads weight across the ground more evenly. Roads built with geogrids tend to last longer in freezing conditions simply because they create a more stable platform against all those harsh winter elements.

Impact of Frost Heave on Traditional Road Reinforcement

Frost heave remains a major problem across colder regions where it wreaks havoc on roadways. Basically what happens is when temperatures drop below freezing, water trapped underneath the pavement turns to ice and pushes the road surface upward. Most conventional reinforcement techniques such as steel mesh or rebar just aren't up to the task in these harsh conditions, which explains why we see so much damage developing over time. Geogrids offer something different though. These grid-like structures spread out the pressure caused by frost expansion much better than traditional approaches, helping keep road surfaces intact despite repeated freeze-thaw cycles. Research shows roads built with geogrid reinforcement suffer far less cracking and buckling during winter months compared to standard construction methods. Road engineers warn that neglecting frost problems leads to constant patching jobs and higher long term expenses. Choosing appropriate materials becomes absolutely critical for infrastructure projects in areas prone to extreme weather fluctuations if we want our roads to last longer without breaking the bank on maintenance down the line.

Best Practices for Geogrid Use in Cold Climates

Selecting the Right Geogrid Material (Biaxial Integral Geogrid Products)

Road building in cold regions presents unique challenges, making the right geogrid material selection absolutely essential for long term stability. Most contractors tend to go with biaxial integral geogrids when facing these tough winter conditions. Tensile strength matters a lot here since it directly affects how well the grid reinforces the road structure against heavy loads and shifting ground. The material needs to be flexible enough too so it won't snap under pressure from freezing soils expanding and contracting season after season. Moisture resistance becomes another major concern alongside extreme temperature tolerance. Looking at industry specs from organizations like ASTM International gives engineers a reliable benchmark for picking quality materials that stand up to harsh northern winters year after year.

Proper Installation Techniques for Geo Mesh Systems

Getting geo mesh systems installed right makes all the difference in how well they work over time, especially where winter gets really harsh. The process starts with good soil prep work first things first. Most folks overlook this step but getting the ground level and packed down properly creates a solid foundation for those mesh layers. When laying out each layer, precision counts because even small mistakes can affect overall stability later on. And don't forget about proper compaction after each layer goes down. Manufacturers have their own specs for installation, so checking those guidelines is pretty much non-negotiable if we want things to last. Take northern Minnesota for instance, where several highway projects used geo mesh during brutal winters. Those installations held up against snow loads and freeze-thaw cycles that would break lesser materials. What works there usually works everywhere else too, provided everyone follows the basics correctly from start to finish.

Integrating Geogrid Retaining Walls for Stability

Geogrid retaining walls offer real benefits for keeping roads stable, especially where winter weather causes problems. The way they work is pretty straightforward actually - the geogrids lock into the surrounding soil, spreading out the weight and stopping erosion issues before they start. From what engineers know about materials science, using these grids properly can really boost how strong and long lasting the wall becomes. Take Sweden for instance, where several highway projects incorporated geogrid technology back in the early 2000s. Maintenance crews there noticed fewer repairs needed over time, plus drivers reported feeling safer on sections with these walls. The flexibility built into geogrid systems means they handle freeze-thaw cycles much better than traditional concrete alternatives. As cities continue building through challenging terrain, this kind of solution keeps gaining traction among civil engineers looking for cost effective yet durable options.

Geogrid vs. Traditional Reinforcement: Cold Region Comparison

Durability in Freeze-Thaw Cycles

When we look at geogrid systems next to old school reinforcement materials, they really stand out when it comes to lasting through those nasty freeze-thaw cycles. Regular materials tend to crack up after all that expanding and contracting from changing temperatures, but geogrids hold together much better. Studies have shown these grids keep their strength even when things get icy, so there's less chance of the whole system falling apart in winter weather. Contractors report seeing fewer problems down the road too. Maintenance crews don't have to fix things as often as they would with other options, which means big money saved in the long run. Since repair work happens less frequently, especially in areas where snow and ice are regular visitors, geogrids make sense both economically and practically for construction projects facing harsh winters.

Long-Term Cost Efficiency in Harsh Conditions

Geogrids tend to be more cost effective in the long run when used in cold regions compared to older methods because they need less maintenance and fixing. Looking at costs shows that while geogrids might cost more upfront, they actually save money down the road. Take roads built with geogrid reinforcement for example these structures hold up better against freeze-thaw cycles and heavy snow loads, so crews don't have to patch them as often. Road engineers who've worked on northern highways report that choosing geogrids makes a real difference in project budgets. They point out that contractors should look beyond just what something costs today and think about how much it will save or cost in five, ten years from now.

FAQs: Geogrid Road Construction in Cold Regions

How Does Geogrid Prevent Rutting on Snow-Covered Roads?

Geogrids really make a difference when it comes to keeping snow covered roads from developing ruts because they spread out weight better and stabilize the ground underneath. When these grids reinforce the base layer of the road, they basically act as a support system that spreads vehicle weight across larger areas. This helps prevent the kind of damage we see during winter months where heavy trucks pass through repeatedly. Many municipalities have reported savings after installing geogrids, both in terms of money spent on repairs and how long the roads actually last before needing work. Some studies indicate roads with proper geogrid installation show about half the rut depth compared to regular roads without them, which explains why so many highway departments now include them in their winter road construction plans.

Can Geogrid Be Combined with Other Geo Grid Solutions?

Putting geogrids together with other types of geo grid solutions works well and actually gives better results when building roads. Take geotextiles for instance. When we combine them with geogrids, they help with drainage issues and make the road stronger under heavy loads. This leads to infrastructure that stands up to wear and tear much better than before. We've seen this work in real world situations where roads needed less fixing over time and lasted longer between major repairs. That kind of outcome saves money in the long run which is why many experts in the field suggest using these combinations. The reason? Different materials complement each other depending on where the road is built and what kind of weather it faces throughout the year.

Table of Contents

-

Understanding Geogrid Road Construction

- What Is Geogrid and How Does It Work?

- Key Advantages of Geogrid Reinforcement

- Challenges of Road Construction in Cold Regions

- Temperature Extremes and Ground Instability

- Impact of Frost Heave on Traditional Road Reinforcement

- Best Practices for Geogrid Use in Cold Climates

- Selecting the Right Geogrid Material (Biaxial Integral Geogrid Products)

- Proper Installation Techniques for Geo Mesh Systems

- Integrating Geogrid Retaining Walls for Stability

- Geogrid vs. Traditional Reinforcement: Cold Region Comparison

- Durability in Freeze-Thaw Cycles

- Long-Term Cost Efficiency in Harsh Conditions

- FAQs: Geogrid Road Construction in Cold Regions

- How Does Geogrid Prevent Rutting on Snow-Covered Roads?

- Can Geogrid Be Combined with Other Geo Grid Solutions?