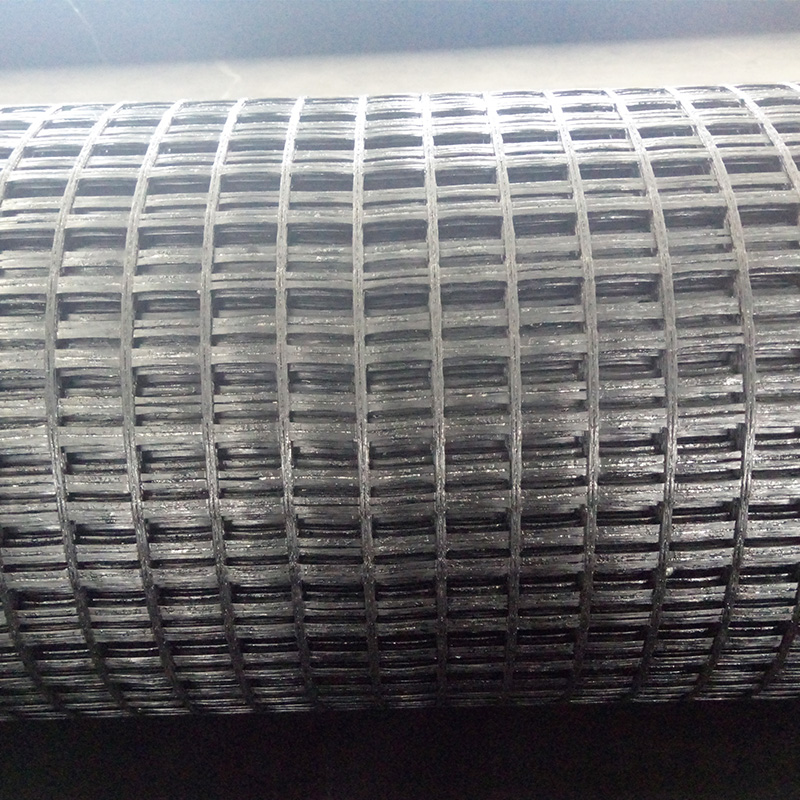

Pet (polyethylene terephthalate) geogrids are made from high-strength polymer sheets extruded into a grid structure comprising integrally connected parallel sets of ribs at acute angles to each other. This structure allows mechanical interlocks with soil or aggregates, forming a composite system to enhance load distribution in construction tasks such as retaining walls and road bases. The non-ferrous material doesn't corrode and provides long-term performance in damp or chemically active environments, exceeding the service life of typical steel reinforcement without the need for special corrosion protection.

Tensile Strength Advantages of PET Geogrids

Molecular Orientation Enhancing Load-Bearing Capacity

This high tensile strength is a result of the engineered alignment of polymer chains during production of PET geogrids. Biaxial stretching generates oriented molecular structure, leading to higher level of crystallinities and minimizing stress concentration sites. This orientation allows geogrids manufactured from PET to have tensile strength greater than 40kN/m, an essential feature for reinforcing structures such as slopes and retaining walls.

Comparative Performance Against Steel Grid Systems

PET replacements have now achieved 85% of steel’s strength-to-weight ratio at 30% less weight. PET, in contrast to steel, resists electrochemical corrosion and its strength does not decay with prolonged exposure to moist environments. Field trials have demonstrated that PET systems provide 22% better long term deformation resistance than steel alternatives, as the elasticated lattice design accommodates ground movement. A 2023 polymer engineering review verifies that PET geogrids comply with AASHTO M288-17 for pavement base use (resistance to permanent deformation) and slashes installation costs by 18-25%!

Carbon Footprint Reduction Using Recycled PET

Incorporating recycled PET in geogrid production reduces carbon emissions by over 60% compared to virgin material processing. Production using 100% recycled PET lowers energy consumption by up to 80% while maintaining equivalent tensile strength. This closed-loop approach diverts plastic waste from landfills and slashes resource depletion.

PET Geogrids vs. Volcanic Ash Composite Alternatives

Eco-Efficiency Comparison in Drainage Applications

PET geogrids outperform volcanic ash composites in hydraulic conductivity due to their engineered polymer structure. Field tests show PET grids achieve 40% higher flow rates in clay-heavy soils. While volcanic composites boast 25–30% lower embodied carbon, their irregular pore distribution limits drainage efficiency under sustained pressure.

Structural Limitations of Natural Fiber Blends

Volcanic ash composites face durability challenges in load-bearing scenarios, with tensile strength reductions of up to 50% occurring after 18 months in humid conditions. Unlike PET's hydrophobic polymer chains, natural fibers absorb moisture, accelerating biodegradation and destabilizing reinforced slopes.

Durability in Extreme Environmental Conditions

Resistance to Acidic Soil and Saltwater Corrosion

PET geogrids deliver unmatched resilience in corrosive environments where traditional materials fail. Their polyethylene terephthalate composition inherently resists chemical reactions with acidic soils and saltwater exposure. Performance validation includes accelerated aging tests showing less than 3% tensile strength loss after 50-year equivalent exposure.

Future Innovations in Sustainable Geogrid Technology

Biodegradable Polymer Research Breakthroughs

Material scientists are pioneering enzyme-triggered biodegradable polymers for PET geogrid applications, targeting complete decomposition within 5 years post-service life without microplastic residues. These innovations utilize modified polyhydroxyalkanoates (PHA) derived from agricultural waste that retain >85% tensile strength during operational phases.

Closed-Loop Recycling System Developments

Advanced depolymerization technologies now enable full-cycle PET reclamation, converting decommissioned geogrids back into virgin-grade polymers. Leading pilot facilities have achieved 97% material recovery rates using energy-efficient continuous reactors, substantially reducing production emissions.

FAQ

What are PET geogrids made of?

PET geogrids are made from high-strength polymer sheets of polyethylene terephthalate, extruded into a grid structure.

Why are PET geogrids preferred over steel grids?

PET geogrids are preferred because they resist electrochemical corrosion, have a significant strength-to-weight advantage, and provide long-term deformation resistance.

How do recycled PET geogrids impact the environment?

Recycled PET geogrids reduce carbon emissions by over 60% compared to those made from virgin materials, while maintaining tensile strength.

How do PET geogrids perform in extreme environments?

PET geogrids resist corrosion from acidic soils and saltwater, and show less than 3% tensile strength loss after simulated 50-year exposure.