Advanced Fiberglass Geogrid Development Expertise

23-Person R&D Team Focused on Geo Grid Innovation

The R&D department has 23 specialists covering areas from materials science to engineering and geotechnical research. Together, these professionals push boundaries when it comes to developing better geo grids, keeping us competitive in this fast moving market place. We've invested heavily in state of the art machinery which lets us test out new grid designs much faster than traditional methods allow. This means we can respond quickly when customer needs change or new problems arise within the industry. Weekly brainstorming meetings keep everyone on the same page while monthly workshops bring fresh perspectives into solving real world issues faced by clients. Our staff also participates in ongoing education programs throughout the year so nobody gets left behind as technology continues evolving rapidly in the field of geogrid development.

Strategic Partnership with Nanjing Fiberglass Institute

Working closely with the Nanjing Fiberglass Institute has really expanded what we can achieve in research. We share technical insights and pool our resources together on several joint projects aimed at creating better performing fiberglass materials specifically designed for geogrids. What comes out of these collaborations gets built right into how we develop our products, so our geogrids last longer and work better across different construction sites and infrastructure projects. Plus, through this partnership we gain entry to some top notch testing labs that help fine tune the reliability of our latest geogrid innovations before they hit the market. When we team up with experts from the institute, it not only deepens our own knowledge base but also means our finished products consistently hit industry benchmarks for quality and performance in geogrid applications.

German-Engineered Production Capabilities

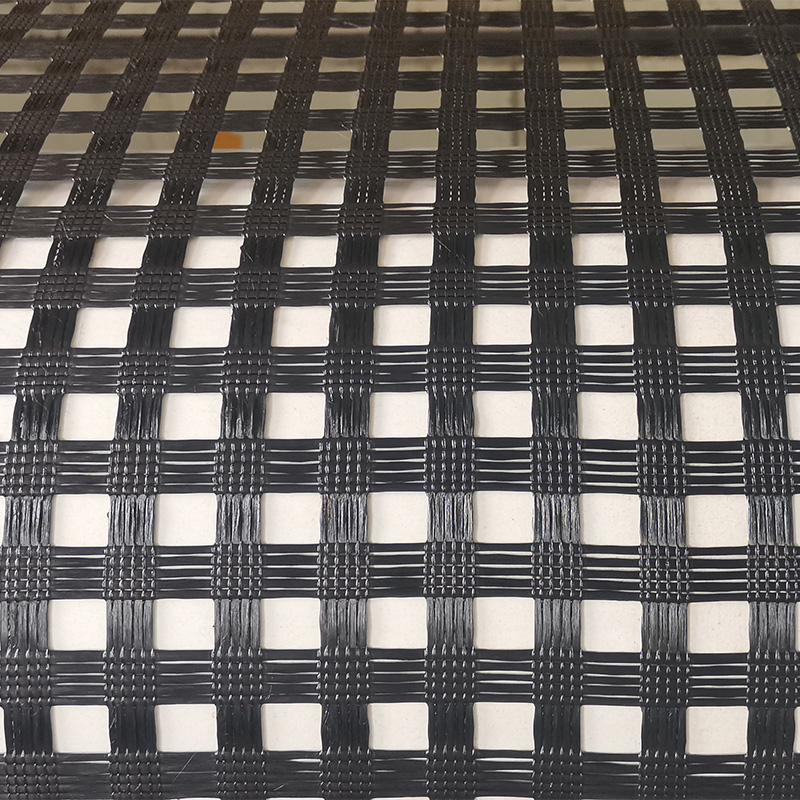

Karl Mayer High-Strength Manufacturing Systems

We rely on Karl Mayer systems to keep our fiberglass geogrid production consistent and accurate. These systems give our products the strong tensile strength needed for things like retaining walls and driveway reinforcement across different engineering projects. What makes these machines so great is their built-in automation which cuts down on material waste while speeding up production times, something that really helps us hit our sustainability targets. The company has long been known for making top quality textile machinery, and this reputation translates directly into reliable geogrids that pass all the tough specs required by construction sites nationwide.

ISO 9001 Quality Management Implementation

Getting ISO 9001 certified shows we really care about making good stuff and constantly improving how we do things in production. Our quality checks happen all through manufacturing, from raw materials right down to finished products, so everything meets those global standards people expect. We run regular checks on our processes too, looking for spots where we can get better at what we do, which keeps everyone accountable throughout the company. When clients see this focus on quality, they know they can count on us, and it helps position us as one of the best manufacturers of geogrids out there. Following ISO 9001 isn't just paperwork for us either—it means our customers actually get reliable products supported by real systems that work day after day.

Sustainable Applications in Civil Engineering

Geogrid Retaining Wall System Optimization

Improving geogrid retaining wall systems brings real improvements to structural strength while using far less material than traditional methods. What makes these developments so important? They help cut down on both environmental impact and project costs for construction work. Take a look at actual projects where geogrid walls were installed in different sectors from highways to commercial buildings, and we see明显 savings in digging out earth and moving materials around. The lighter weight of modern geogrid products means contractors can build strong foundations without wasting resources, which naturally supports greener construction approaches. Field data collected over years shows these upgraded systems hold up well over time, staying stable even under tough conditions. Beyond just making construction faster and cheaper, these systems actually contribute to broader sustainability targets that many companies now prioritize.

Geo Mesh Solutions for Infrastructure Projects

Geo mesh has proven itself indispensable when it comes to stabilizing soil and controlling erosion during infrastructure work. What makes this material stand out is how well it adapts to all sorts of landscapes from steep mountain slopes to coastal areas battered by storms. Construction companies find it works great in almost every scenario they encounter on site. Looking at recent studies, we see that manufacturers are making their geo mesh products greener by following tighter environmental standards, which helps the whole construction industry move toward more sustainable practices. Working closely with civil engineers gives manufacturers real world feedback about how these meshes perform under actual field conditions. This kind of collaboration keeps pushing the boundaries of what geo mesh can do, resulting in better designs that actually solve problems faced by engineers working on complicated infrastructure projects day after day.

Global Market Impact Through Technical Leadership

CE-Certified Geogrid Driveway Solutions

Getting CE certification matters a lot for geogrid driveway products since it shows they follow European health and safety rules. This actually helps sell these products better across Europe and beyond. Our geogrid systems are built tough enough to handle serious traffic weight, so they work great whether someone needs them for their home driveway or for bigger commercial projects. People who have used these grids often talk about how well they perform and just how long they last without breaking down, something that definitely adds trust when we're trying to convince others about their quality. Plus, we can tweak things according to what each client specifically needs for their particular job site, which means more businesses choose us over competitors who don't offer such flexibility.

Serving 80+ Countries with Custom Specifications

The company's distribution channels stretch across more than 80 nations, showing just how far reaching our operations have become worldwide. Our geogrid offerings come in various specifications designed specifically for different regions, meeting local building codes while holding up against everything from desert heatwaves to Arctic cold snaps. Working hand in hand with regional partners has proven invaluable when breaking into new markets, as these connections help build credibility within communities where we operate. Looking at recent figures, exports have jumped significantly over the past few years, pointing to growing interest in quality geogrid solutions around the globe.