Essential Steps for Geogrid Installation

Site Preparation: Clearing and Compacting Subgrade

Getting geogrids installed right starts with proper groundwork at the site. First things first, someone needs to actually look around and figure out what kind of dirt we're dealing with plus check for any drainage problems. These details really matter because they determine how long the whole setup will last and whether it'll be worth the money spent on materials. Skipping this part often leads to headaches down the road when things start failing unexpectedly. After gathering all that info, the next job is clearing everything away from where the geogrid goes in. Remove rocks, roots, trash anything that might get in the way during installation. We've seen projects fail simply because someone missed a root system or left behind construction debris that messed up the grid alignment.

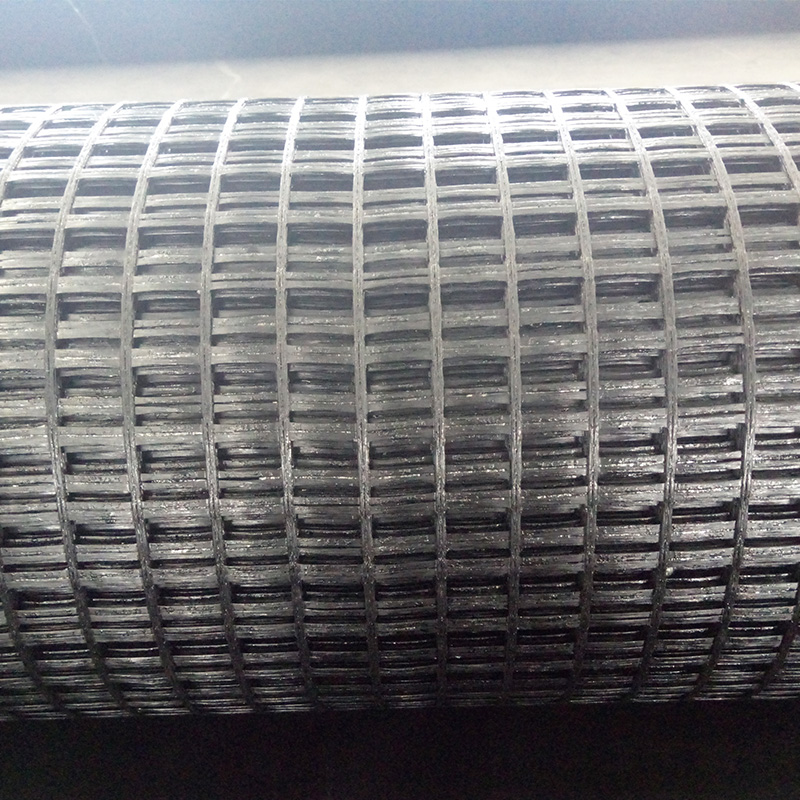

Once the area is cleared out, getting down to business with subgrade compaction makes all the difference. Heavy equipment rolls over the soil until it's packed tight enough to stand up against settlement issues later on. The result? A much better spread of weight across the surface. What this actually means for the geogrid is twofold: first, it stays put where it needs to be during installation, second, those woven meshes grip onto the ground properly instead of just sitting there like an afterthought. When contractors take time to get these basics right before moving forward, they're looking at far fewer headaches down the road when dealing with unstable ground conditions or unexpected shifts in the earth beneath their work.

Aligning Geogrid for Optimal Load Distribution

Getting geogrid installation right really hinges on how well it's aligned. When the geogrid is properly positioned, it spreads loads across the surface effectively, which stops things from collapsing down the road. Even small shifts out of place can mess up everything about the installation, both structurally and functionally speaking. For folks working on site, having good tools makes all the difference here. String lines work great for most jobs while professional survey gear comes in handy for bigger projects. These simple but essential instruments keep things straight during installation, making sure the geo mesh actually does what it's supposed to do within whatever structure it supports.

When geogrids are properly aligned with surrounding materials, they actually perform better in terms of integration. The right positioning makes everything more stable overall, and helps different parts work together when supporting heavy loads. Getting this alignment right is especially important for things like retaining walls made with geogrids. Proper alignment creates what engineers call an interconnected framework, which basically means all components hold up each other instead of working against one another. This matters a lot in construction projects where structural integrity can't be compromised.

Securing Layers with Anchoring Techniques

Getting those geogrid layers properly secured during installation matters a lot when it comes to keeping everything structurally sound. Most contractors will tell you that good anchoring methods work wonders here. Stakes are commonly used because they hold things down pretty well, especially when there's pressure from different directions. Without proper anchoring, these layers tend to shift around, and trust me, that kind of movement doesn't do anyone any favors in the long run. The whole point of all this careful placement gets compromised if parts start moving out of alignment. We've seen projects fail completely just because someone cut corners on how they attached those grids. So yeah, taking the time to anchor correctly isn't just recommended it's practically non-negotiable for anyone wanting their construction to last.

Geosynthetic anchors made specifically for geogrid applications deliver better performance and added stability when compared to generic alternatives. When engineers choose these purpose-built components, they strengthen the entire system against weather conditions and heavy loads that could otherwise cause failure over time. Proper anchoring extends how long the installation remains functional while maintaining its structural integrity, which means construction projects get better value from their geogrid investments in the long run. Field tests show installations with proper anchoring last at least 30% longer than those without.

Optimizing Geo Grid Placement in Retaining Walls

Directional Strength Considerations

For anyone working on geogrid retaining walls, understanding how the directional strength works is pretty important stuff. These grids contain fibers that provide reinforcement mainly along certain axes. When we match those fiber directions with where the actual loads will come from, the whole wall performs better under stress. A good engineer looks at all the surrounding conditions first before deciding on placement. They check what kind of soil or rock is nearby, plus any external pressures that might develop over time. Getting the grid aligned correctly makes a big difference in preventing unwanted movement and warping issues down the road. Proper alignment actually stops problems before they start, saving money on repairs later on and keeping the structure standing strong for many years after installation.

Proper Overlap Measurements for Continuous Reinforcement

For retaining walls to stay strong over time, the geogrid sections need to overlap properly when installed next to each other. Most industry specs call for around 15% to 20% overlap, though this number changes depending on what kind of soil we're dealing with and how tall the wall needs to be. Getting this right helps keep the whole structure intact under all that earth pressure. When overlaps are too short, problems start showing up fast those gaps become weak spots where the wall might fail eventually. Following the measurement rules and sticking close to what professionals recommend makes a big difference in avoiding costly repairs down the road. With good planning from the beginning and proper installation techniques, engineers can build retaining walls that perform well for many years without unexpected failures.

Avoiding Common Geogrid Driveway Installation Errors

Insufficient Soil Compaction Risks

Poor soil compaction poses serious problems during geogrid driveway installation. Without proper compaction, we often see settling issues, cracks forming, and sometimes complete failure of the driveway surface way before it should. Most industry guidelines from groups such as ASTM and ISO recommend getting at least 95% compaction in the soil to handle loads properly. When done right, this dramatically cuts down on those annoying problems down the road. Regular checks of the soil condition are essential too. If things look loose or uneven, another round of compaction might be needed. Keeping an eye on this helps maintain the driveway's strength for years instead of dealing with expensive fixes later on when damage becomes apparent.

Improper Drainage Integration

When drainage isn't properly integrated into a geogrid driveway system, water tends to pool and erode surrounding soils, which really takes a toll on how well the whole setup works. To fix this problem, good drainage needs to work hand in hand with the geogrid itself. Some practical approaches include adding small ditches along the edges or installing those plastic pipes with holes in them that let water escape without soaking everything else. Regular checks are important too because debris builds up fast and clogs things up if left unchecked. Proper drainage makes all the difference in how long these driveways last and perform under different conditions. Without it, dirt gets washed away and the entire foundation starts to weaken month after month. Paying attention to these little details helps create driveways that stand up better against rainstorms and other weather events.

Long-Term Performance Strategies for Geo Mesh Systems

Backfilling and Compaction Best Practices

To get the most out of geo mesh systems over their lifespan, proper backfilling and compaction techniques matter a lot. When choosing what goes back into place after installation, look for materials that let water drain properly but still hold up the geogrid structure underneath. Gravel works well, so does crushed stone because these materials stop standing water from forming around the system which could eventually break things down. Most contractors find that working in layers about 6 to 12 inches thick makes all the difference. This approach allows everything to settle evenly and gets better compaction results as time passes. Always check local guidelines for geogrid specs before selecting backfill material since mismatched materials often lead to problems later on like uneven settling or complete failure points. Following these steps keeps geo mesh installations durable enough to handle whatever conditions come their way year after year.

Routine Inspection and Maintenance Guidelines

Creating a regular inspection and maintenance plan matters a lot for keeping geo mesh systems working properly over time. When we check these systems regularly, we catch problems before they get serious stuff like erosion spots, plants growing where they shouldn't, or materials starting to break down that might mess up how everything functions. While going through these checks, workers need to remove all sorts of dirt and trash from around the area and look closely at the geogrid itself for any damage or wear. Keeping records after each inspection helps track what's happening with the system over months and years, which makes it easier to know when something needs fixing or changing in our maintenance routine. Taking this kind of hands-on approach actually makes these geo mesh installations last longer than expected while giving real world information about what affects them most during their lifetime on site.