Understanding Geogrid Road Design Fundamentals

The Role of Geogrids in Modern Road Engineering

Geogrids act as important reinforcement materials in today's road building work, helping spread out weight across bigger areas. When weights get distributed this way, there's less pressure on the ground below, so roads stay stronger overall. For actual road surfaces, these grids really help stop uneven sinking problems that would otherwise ruin the road surface quality and shorten how long roads last. Studies show something interesting here too roads built with geogrids tend to last around 30% longer than those without them, though results vary depending on conditions. Longer lasting roads mean fewer fixes down the road and better performance for drivers, which makes geogrids worth considering despite their initial costs.

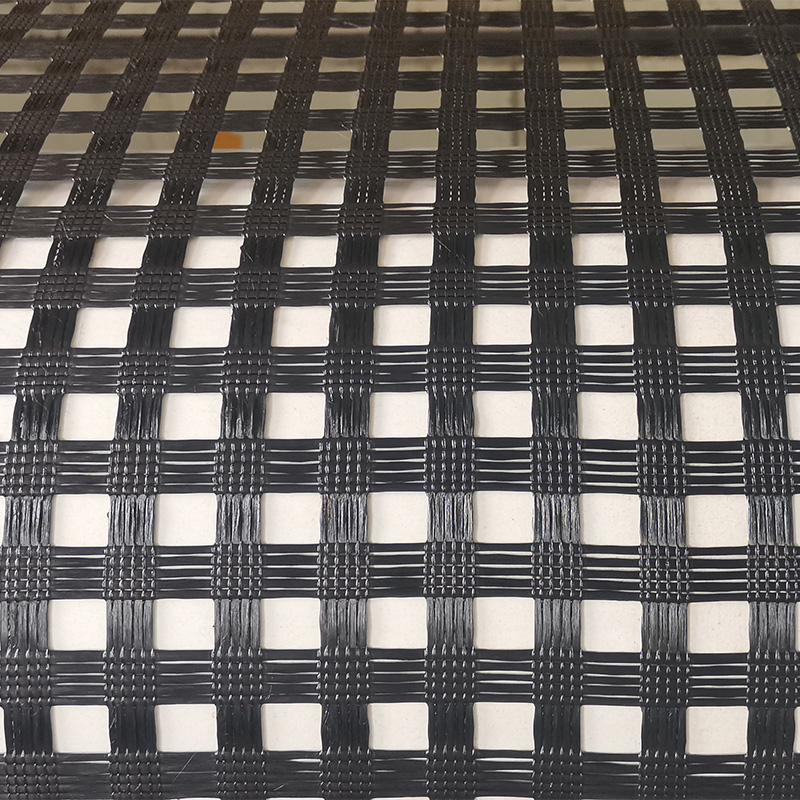

Types of Geogrids for Road Projects: Uniaxial vs. Biaxial

Picking the right geogrids for road work matters a lot in terms of long term success. Uniaxial options work best when dealing with forces coming from just one direction. These are commonly used for stabilizing slopes and building retaining walls where directional strength is key. Biaxial geogrids tell a different story though. They spread out pressure across several directions at once, which explains why they're so popular for reinforcing road bases. Whether to go with uniaxial or biaxial really comes down to what the job needs. Soil composition plays a big role here along with how much traffic will be passing over the surface. Getting this right means engineers don't waste money on overkill solutions while still meeting safety standards. Most experienced contractors know that taking time to evaluate site conditions before purchase saves headaches later on during construction phases.

Addressing Road Construction Challenges with Geogrids

Managing Traffic Load Stress with Geogrid Reinforcement

Geogrids really help manage all that stress from traffic loads by making road bases stronger in tension. When engineers include these grids in their road plans, they can actually cut down on how thick the pavement needs to be sometimes by around 25%. That means big savings on materials for the project budget. Plus, thinner pavements mean we're using less stuff overall, so there's a smaller footprint on the environment too. Real world testing shows roads built with geogrid reinforcement just don't deform as much under heavy truck traffic compared to regular roads without them. So all this research basically proves why geogrids work so well at keeping roads intact even after years of constant use and wear.

Adapting to Diverse Soil Conditions: From Soft Soils to Expansive Clays

Geogrids work well in all sorts of soil situations from soft ground to tricky expansive clays. What makes these grids so valuable is their ability to hold down unstable soils where regular construction materials just won't cut it. Tests conducted over several years indicate that when placed correctly, geogrids significantly cut down on problems like soil heaving and shrinking that plague roads built on expansive clay. For civil engineers working on road projects, this means they can build stronger transportation systems even in poor soil conditions without constant maintenance headaches. The result? Roadways that last longer and require fewer repairs despite whatever weird soil challenges Mother Nature throws at them.

Preventing Cracks and Extending Road Lifespan

Keeping cracks at bay during road building work matters a lot when it comes to how long roads last before needing repairs. Geogrid materials help out here because they strengthen the road base underneath, spreading weight and pressure more evenly throughout the pavement layers. When roads are built with these grids, there tend to be fewer cracks forming, so crews don't have to fix things as often. Plus, roads with geogrids hold up better against all sorts of weather beatings, from hot summers melting asphalt to freezing winter temperatures causing expansion issues. Real world data shows that roads constructed using geogrid technology typically stay in good condition for many more years than those without. For municipalities looking to save money on constant road fixes while still providing decent infrastructure, geogrids offer both environmental benefits and financial sense in the long run.

Implementing Geogrids: Design and Installation Best Practices

Key Considerations for Geogrid Road Design

Starting a geogrid road design project requires looking at several important things to get good results. Load requirements, what kind of soil we're dealing with, and local weather conditions all matter a lot. These elements directly affect which geogrid system works best for the job. Working closely with geotechnical experts and construction teams makes sense because they know how to adjust geogrid applications based on what problems need solving on site. Following established industry standards isn't just paperwork either it actually helps optimize how well everything performs while keeping projects within legal boundaries. When all these points are properly considered, the geogrid should function correctly over time. This approach explains why geogrids have become so popular in road work today, especially for things like building stable retaining walls or creating durable driveway surfaces where traditional methods might fall short.

Step-by-Step Installation for Long-Term Stability

Getting geogrids installed correctly makes all the difference when it comes to keeping roads stable over time. First things first, the ground needs thorough prep work before anything else happens. Then comes placing those grids just right in the designated spots, making sure everything sits properly without gaps. After that, compacting the surrounding soil becomes essential too. Taking care during each step helps prevent big problems down the road while maximizing how well the grids actually reinforce the structure beneath them. Stick to this methodical process from start to finish and many common issues simply won't arise. Regular checks after installation matter as well. Look out for signs of settling or shifting materials which could compromise the whole system eventually. With proper attention given throughout the entire project lifecycle, both wall structures and driveway surfaces benefit greatly. Maintenance costs drop significantly and lifespan increases substantially, allowing roads to handle heavy traffic loads and adapt better to different types of soils without breaking apart prematurely.