What Is Asphalt Geogrid? Definition and Core Functions

Asphalt geogrid represents a type of geosynthetic product specifically engineered for reinforcing road surfaces. When installed properly, these materials help spread out the weight of vehicles over larger areas, which takes pressure off the ground beneath the pavement. Made primarily from strong polymer materials, they form what amounts to an invisible support network inside the asphalt layer itself. What makes them so effective? Well, when traffic passes over roads with geogrid reinforcement, the forces get distributed differently compared to regular pavement. This means less cracking develops over time since the stress points aren't concentrated in one spot. Road engineers often place these grids strategically during construction projects because doing so can actually make roads last longer between maintenance cycles, saving money in the long run for municipalities and transportation departments alike.

Asphalt geogrids basically work to make roads last longer and perform better over time. These grid-like materials get placed inside asphalt pavements where they act like internal support structures. What this does is stop those annoying cracks from spreading across the surface, especially after the initial paving starts to show age. When trucks and cars keep rolling over the same spots day after day, the geogrid helps spread out all that pressure so the road doesn't just sink or break apart completely. Road builders find these grids particularly useful because while they strengthen the pavement right away, they also cut down on how often crews need to come back for repairs later on. Municipal budgets love this since fixing potholes costs money every single year. Cities that have started incorporating geogrid technology report fewer complaints about cracked streets during winter months when freeze-thaw cycles normally wreak havoc on regular asphalt.

How Asphalt Geogrid Enhances Road Surface Integrity

Subgrade Stabilization for Smoother Pavement

Getting the subgrade right is really important if we want smooth roads in the long run, and asphalt geogrids are a big part of making that happen. These grids basically spread out the weight over a larger space instead of letting it all concentrate in one spot. That means less pressure on any single point of the road base. When engineers put these grids into the pavement layers during construction, they're actually creating roads that hold up better against cracks and sinking spots. Some field tests back this up too roads with proper geogrid reinforcement tend to stay flatter for longer periods, which translates to fewer potholes and overall better driving experience for everyone using those roads day after day.

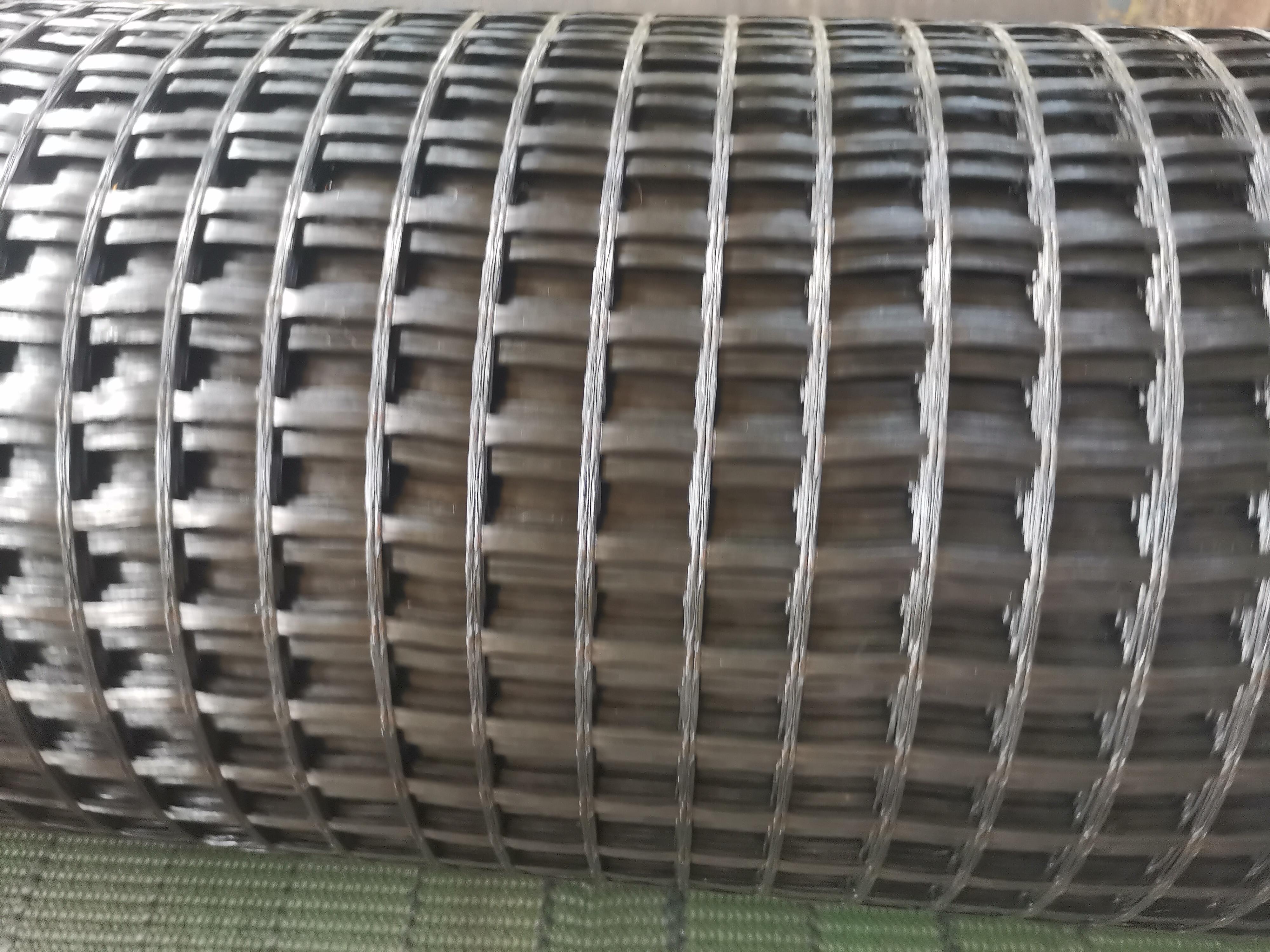

Load Distribution Through Biaxial Geogrid Design

Biaxial geogrids work wonders for how weight spreads across roads, making these structures much stronger overall. The key lies in their distinctive grid pattern which helps spread out pressure more evenly across surfaces. Studies from civil engineers point to real benefits here too these grids last longer on pavements than traditional options. When roads face repeated traffic or sudden impacts, biaxial geogrids manage these forces better, cutting down on stress points that usually cause cracks and potholes. What this means practically is longer lasting roads that can stand up to heavier vehicles without breaking down as quickly.

Reducing Rutting and Soil Contamination

Asphalt geogrids help cut down on rutting problems because they give ongoing support to different road layers. Rutting happens all the time on busy roads, especially during hot weather when traffic volumes spike. When we install these grids, they basically act like extra armor for the road structure while keeping it looking good over time. Another benefit comes from how these materials handle water flow better than traditional methods. Better drainage means less standing water soils get contaminated from excess moisture buildup. Fewer potholes mean less money spent fixing roads later on, plus drivers end up with smoother rides for longer periods before needing major repairs again.

Preventing Cracks and Deformation with Geogrid Technology

Mitigating Reflective Cracking in Asphalt Layers

Geogrid tech really helps stop those annoying reflective cracks in roads and highways. What happens is these grids form a sort of buffer layer between asphalt layers that takes up a lot of the stress when vehicles pass over. This isn't just theoretical stuff either pavement engineers see actual results where cracks take longer to appear and spread from below. Studies on road surfaces show that installing geogrids cuts down on reflective cracking problems significantly. Strata Global's research points out how these materials work as kind of shock absorbers for road surfaces, stopping both top-down and bottom-up cracks from getting all the way down to the base layers. Take the airport runway project in Ahmedabad for instance geosynthetic materials were used there and they made a noticeable difference in how long the pavement lasted before needing repairs. Contractors who've worked with geogrids often say it's worth the investment because it saves money on maintenance costs down the road.

Role of Geo Composites in Lateral Restraint

Geo composites help hold road structures together laterally so they don't deform over time. When these materials support pavement layers from side to side, they really make a difference in how long roads last before needing repairs. As reinforcing elements, they do more than just strengthen roads; they actually manage how weight gets distributed across surfaces, which means less chance of cracks forming when heavy vehicles pass through regularly. Strata Global's research shows that these composites often team up with geogrids for better results, something we see all the time in real world applications where pavement stays intact longer. For roads built on tricky ground or ones handling lots of traffic, embedding these special composites makes all the difference. They keep everything in place despite constant pressure, meaning longer lasting roads and fewer trips back for fixes down the road.

Installation Best Practices for Long-Term Smoothness

Subgrade Preparation Techniques

Getting the subgrade ready is really important if we want geogrid materials to work properly in the long run. The basic idea is to clear away anything big that might get in the way during installation - think trees, big rocks, and those deep tire tracks left behind after equipment passes through. Most contractors know they need to do this because leftover debris just causes problems later on. Organizations such as ASTM set down what needs to happen with their specifications for clearing and leveling surfaces. One thing worth mentioning specifically is making sure the ground isn't muddy or too loose, since soft spots will definitely mess with how well the geogrid does its job. Following these rules helps create a good base layer that spreads weight evenly across the area and stops dirt from washing away over time, which saves money in maintenance costs down the road.

Optimal Placement of Geo Mesh Layers

Correct placement and alignment of geo mesh layers are vital for overall pavement performance. Properly aligned geo mesh can significantly improve load distribution and extend pavement life. For effective layer placement, standard engineering insights recommend several key actions:

- Lay the geo mesh parallel to or at right angles to the road centerline.

- Maintain even spacing and continuity of the mesh layers for maximal reinforcement.

- Secure the mesh with fill material to ensure stability before fill placement, avoiding direct construction traffic on the exposed mesh.

Following this checklist not only optimizes performance but also ensures the geo mesh provides the intended structural benefits.

Compaction Guidelines for Maximum Efficacy

Getting the most out of asphalt geogrids means sticking closely to compaction rules during installation. Field observations from countless road construction jobs show just how critical good compaction practices really are. Contractors often recommend using graded aggregate material for backfill because it makes reaching optimal density much easier in practice. Proper mechanical compaction equipment matters too - rollers need to be set according to what works best for each particular job site conditions. Soil composition plays a big role here, so experienced crews will adjust their approach based on local factors like moisture content and subgrade stability. When all these elements come together correctly, the end result is not just a smoother ride but also a road surface that lasts significantly longer under normal traffic loads without developing premature cracks or rutting issues.

Cost-Benefit Analysis of Asphalt Geogrid Implementation

Reduced Maintenance Costs Over Time

Putting asphalt geogrids into place really cuts down on maintenance expenses, which means big savings over time for any infrastructure work. These grids act as a sort of reinforcement underneath the road surface, stopping those annoying cracks from forming and keeping the pavement looking good longer. Fewer potholes mean less need for crews coming out with their patching equipment every few months. Some research shows that roads with these geogrid layers might save around 30 percent in repair bills throughout their whole life span. That makes sense when planning new roads or fixing old ones. So while nobody loves spending money on roadwork, adding geogrids actually extends how long roads stay in decent shape without breaking the bank so much.

Extended Road Lifespan vs. Initial Investment

While putting money into geogrids may look expensive at first glance, the payoff comes through much longer lasting roads. What happens is that those higher upfront installation costs get balanced out when we consider how much longer the pavement actually lasts before needing replacement. Studies show that when roads have geogrid reinforcement, they can last almost twice as long as regular ones, which means fewer big repair jobs down the line. Field engineers who've worked on these projects point to how geogrids help spread weight across the road surface more evenly and take pressure off vulnerable spots. Looking at things from a practical standpoint, comparing what we spend initially versus what we save over decades makes a strong case for using geogrid technology if we want our infrastructure to stand the test of time without breaking the bank repeatedly.