Understanding Geogrid Retaining Walls

What Are Geogrid Retaining Walls?

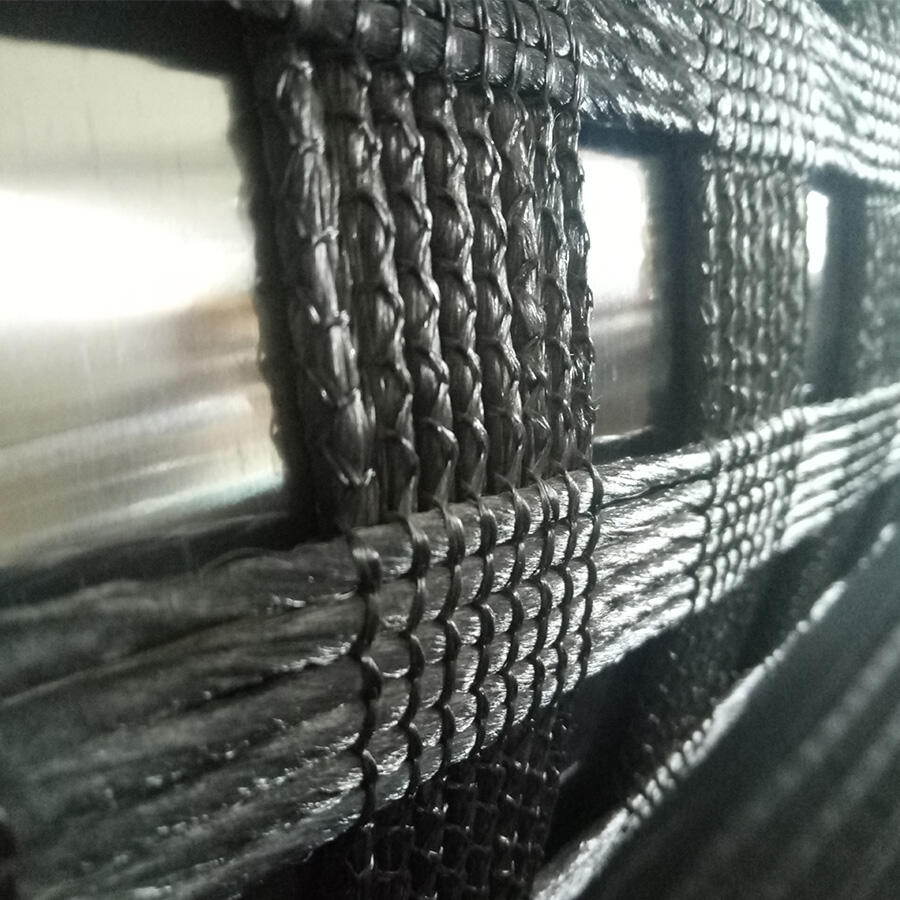

Geogrid retaining walls work as earth retention systems where geogrid material supports and holds back soil. These wall systems use special reinforcement tech to build stable slopes that stop soil from eroding away while keeping everything intact. Most geogrid layers come from plastic stuff like polypropylene, giving them good stretch resistance and flexibility needed for wall stability. What makes these grids so effective is their ability to handle heavy weights without breaking down, which means lower chances of wall collapse. That's why engineers often specify them for big projects including roads, highways, and bridge approaches where structural reliability matters most.

Key Components: Geogrid, Backfill, and Drainage

When building geogrid retaining walls for roadsides or slope stabilization projects, there are basically three main parts involved: the geogrid itself, the backfill material, and proper drainage setup. The geogrid acts as the backbone of the wall, giving it strength to hold up against heavy weights without buckling. Contractors pack backfill materials tightly against this grid framework, creating a solid mass that supports the whole structure and makes it stand firm over time. Without good drainage, water buildup behind the wall can cause serious problems down the road. That's why most installations include things like drain pipes with holes along them plus layers of gravel beneath the soil. These drainage features let water escape safely instead of pooling behind the wall, which would eventually lead to erosion issues and possibly even structural failure if left unchecked.

Applications in Modern Construction

Geogrid retaining walls find their way into all sorts of places these days - think highways, shopping centers, even backyard landscapes. They really come into their own when dealing with slopes that want to slide down or hillsides needing extra support. Take road widening projects for instance, or new city developments where space is tight against natural terrain. These walls just keep standing there year after year without much fuss. Construction reports over the past few years show something interesting happening too. More engineers are specifying geogrid systems in their blueprints because they actually work better at preventing accidents while costing less money in the long run compared to traditional methods.

Design Principles for Geogrid Retaining Walls

Geotechnical Analysis and Soil Compatibility

When constructing a geogrid retaining wall, geotechnical analysis plays a key role in figuring out what kind of soil we're dealing with. Engineers need to know about different soil types, how much weight it can hold, and what kind of weather conditions exist at the site before they can make smart decisions about design. All these elements affect whether the structure will stand strong and work well together with the geogrid material used. The numbers gathered during soil testing give important clues about how compatible the soil actually is with various geogrid options. This information helps pick the right materials so the finished wall can handle things like heavy rain, temperature changes, and other forces without failing after just a few years.

Incorporating Biaxial Geogrid in Structural Design

When engineers include biaxial geogrids in their designs, they get better stability and more even load distribution across retaining walls. The difference between regular uniaxial grids and biaxial ones is pretty straightforward really. While uniaxial grids only strengthen in one direction, biaxial versions work in both vertical and horizontal planes. This dual-directional reinforcement makes them particularly useful for tricky construction sites where forces come from multiple angles at once. For instance, highway embankments or bridge abutments often need this kind of support system. Many civil engineers have found that incorporating biaxial geogrids leads to fewer maintenance issues down the road. Looking at actual construction sites, it becomes clear why these materials are becoming so popular. Cross-sectional drawings typically show how layers of geogrid interlock with soil masses, creating a stronger composite material that resists movement under pressure.

Drainage Systems and Erosion Control

Good drainage makes all the difference when it comes to how long geogrid walls will last and how well they perform over time. When water builds up behind these structures without proper outlets, the pressure can literally push them out of alignment until they collapse completely. Most engineers incorporate special drainage solutions during installation, often combining standard geogrid materials with extra permeable layers that let excess moisture escape safely away from the wall face. The soil itself needs to be considered too - if it doesn't allow water to pass through naturally, problems will develop no matter what kind of fancy materials were used. Field data indicates around 60% of failed retaining wall installations had major issues with their drainage setup from day one. That's why smart contractors always allocate extra time upfront to plan drainage details properly before pouring any concrete or installing those expensive geogrid components.

Step-by-Step Construction Process

Site Preparation and Excavation

Getting the ground ready comes first when building a geogrid retaining wall. There are quite a few things to do here. Start by checking out the soil conditions and how the land slopes naturally. Then clear away all the junk and plants from the spot. Grading the earth properly makes everything stable for what's coming next. Excavation needs to be done right too because if the dirt shifts while we're working, it can really mess up the whole wall later on. Safety should always come first, so wearing proper gear matters a lot. Big machines like excavators and bulldozers get the job done faster, but operators need training to handle them safely around other people. Following those OSHA rules isn't just paperwork stuff either; it keeps everyone safe now and helps the wall last decades instead of years.

Laying Geogrid Layers: Orientation and Tensioning

Getting geogrid layers right makes all the difference when building strong retaining walls. The key thing is making sure the geogrid runs along where the strongest pulling forces happen, typically at a right angle to the wall itself. Don't forget about tension either because if the grid sags too much, it messes up how weight gets spread out over time. Most professionals stick to established best practices during installation just to keep things up to standard. These recommendations basically say maintain even tension throughout every single layer so the geogrid can actually do its job reinforcing the whole structure properly.

Backfilling and Compaction Techniques

What kind of material gets used behind a retaining wall really affects how stable it stays over time. People often consider options like regular dirt, crushed stone, or even repurposed construction waste. Gravel works great when good drainage is needed, but those recycled materials can save money although they sometimes need extra support structures. Getting the compaction right matters a lot too because poor packing leads to settling problems down the road, and that's what causes walls to fail eventually. The best approach tends to be spreading out the fill material evenly across the area and then pressing it down carefully in thin layers rather than trying to do everything at once. Contractors should watch out for things like not packing enough or leaving gaps where material bunches up on one side since these issues will shorten the life of any retaining wall project.

Case Studies: Geogrid Retaining Walls in Action

Landslide Repair at Wheeler Army Airfield, Hawaii

Wheeler Army Airfield on Oahu ran into serious problems when unstable soil caused a major landslide at one of their facilities. The main problem turned out to be weak soil composition that required something durable enough to hold the slope together and stop any more slides from happening. They ended up installing these special geogrid retaining walls as the fix. These grids basically lock the different soil layers together so they can handle all that sideways pressure coming off the hillside behind them. After installation, things looked much better. Site engineers actually commented how well the system worked over time, noting that it kept performing reliably even through heavy rains and other weather challenges that typically cause issues for similar installations elsewhere.

The Parklands of Floyds Fork: Aesthetic and Structural Success

When developing the Parklands along Floyds Fork, designers aimed to create something that looked good while standing up to real world conditions. They went with geogrid retaining walls because these structures actually do two things at once supporting the earth behind them and looking pretty decent while doing it. The actual installation used this special grid material to strengthen slopes and hillsides without making everything look artificial or out of place. After building was complete, inspections showed that the walls held up just fine against erosion and weathering. Plus, visitors started taking notice of how much better the whole area looked compared to other parts of the park where plain concrete walls stood out like sore thumbs. So basically, what started as an engineering decision turned into a win for both functionality and aesthetics.

Geo Grid Driveway Reinforcement Examples

Geo grids work really well for reinforcing driveways and tend to make them last much longer while handling heavier loads without problems. Take a look at what happened in several real world situations where people used these grid systems under their driveways. The results were pretty impressive when it came to stopping those annoying ruts from forming and cutting down on how often repairs needed to be done. Some actual projects showed that maintenance bills dropped around half after installing geo grids beneath the surface. What makes these grids so good is their ability to spread out weight better across the ground, which means the driveway itself doesn't get damaged as easily over time. This kind of reinforcement helps avoid all sorts of typical driveway issues, making it a smart investment for anyone looking to save money on fixes in the long run.

Benefits of Geogrid-Reinforced Structures

Cost-Effectiveness vs. Traditional Retaining Walls

Geogrid retaining walls offer a budget-friendly option compared to standard concrete alternatives. Most traditional retaining walls constructed from concrete materials tend to come with hefty price tags because they demand extensive footings and structural reinforcements. Geogrid systems work differently by incorporating special polypropylene fabrics designed to stabilize soil structures, cutting down on upfront building expenses significantly. Looking at the big picture, these geogrid installations actually save money in the long run since they don't need constant repairs or replacements like conventional walls do. According to several industry reports from recent years, companies that switched to geogrid technology saw noticeable savings across multiple projects. Contractors report reduced downtime for maintenance and fewer material waste issues, making geogrids increasingly popular among civil engineers working on major infrastructure developments where cost efficiency matters most.

Flexibility in Challenging Terrains

One major plus of geogrid solutions lies in how well they work across different types of ground and weather conditions. The retaining walls made with geogrids are pretty flexible stuff, which means they fit right into those tricky spots where regular wall systems just don't hold up. Take mountain roads or landslide-prone areas for instance. Real world projects show that when engineers put geogrids to work in rough terrain, they stabilize soil effectively even on all sorts of uneven ground. Civil engineers point out something interesting about these grids too their layers can be tweaked easily to match whatever slopes or soil differences come up during construction. And let's face it, this kind of adaptability keeps buildings and infrastructure standing firm no matter what Mother Nature throws at them.

Long-Term Durability and Low Maintenance

Geogrid materials last a really long time because they don't break down easily over years of exposure. This means the structures built with them tend to stay strong for decades longer than what we see with regular walls. When looking at actual construction sites, engineers notice something interesting about walls reinforced with geogrids versus those without any reinforcement. The ones with geogrids just need maintenance every few years instead of almost annually. Some field reports show maintenance costs dropping by around 40% when using these materials. Crews who actually maintain these walls report spending way less time on repairs during routine inspections. Combine all this with the fact that geogrids basically take care of themselves once installed, and it becomes clear why so many civil engineers specify them for projects where budget constraints matter but structural integrity cannot be compromised. For municipalities building retaining walls along highways or residential developments near slopes, geogrid technology offers both wallet-friendly benefits and peace of mind regarding future performance.