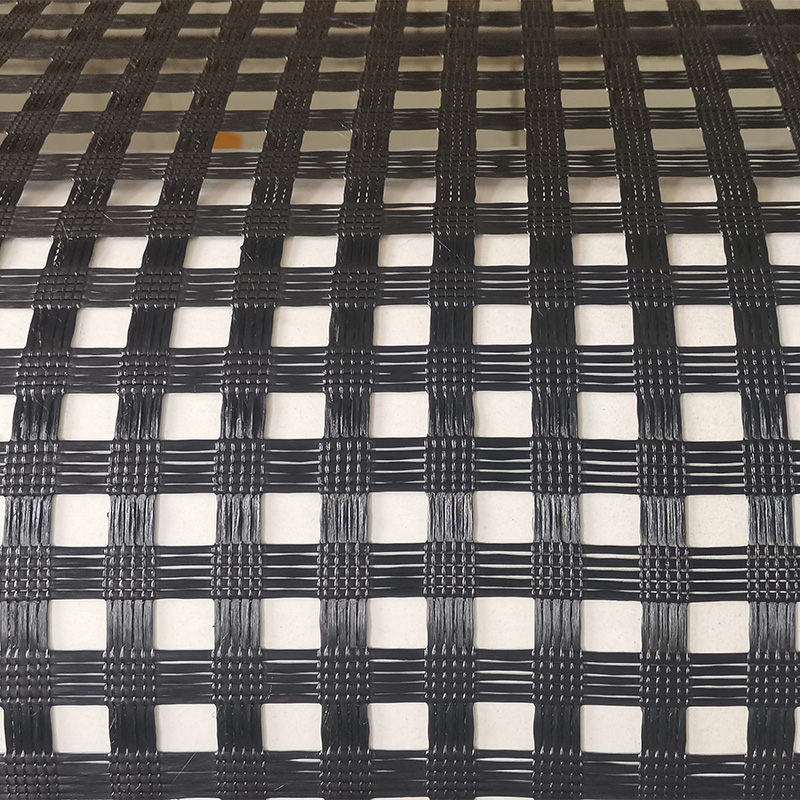

How Fiberglass Geogrid Enhances Road Durability and Cost Efficiency

Mechanics of Load Distribution and Crack Prevention

Fiberglass geogrids help roads last longer because they spread out the weight over a bigger area, which cuts down on those stress points that lead to cracks forming. When roads get hit with lots of heavy trucks day after day, this kind of load spreading really matters for keeping everything intact. What's great about fiberglass is how strong it is when pulled, so even when forces try to warp things, the grid holds firm and keeps asphalt surfaces from buckling. Some research shows these grids can cut back on reflective cracking in asphalt by around 30 percent give or take, which means better performing pavements overall. Road builders have found through experience that incorporating fiberglass geogrids into their projects leads to roads that stay in good shape much longer while saving money in maintenance costs down the line.

Extending Pavement Lifespan Through Reinforcement

Adding fiberglass geogrids to road construction work actually makes roads last much longer than regular surfaces without them sometimes doubling their useful life according to field tests. Studies have found these reinforced roads stand up better against cracks and potholes caused by repeated traffic loads. From a sustainability standpoint, life cycle assessments show that using fiberglass materials gives better performance year after year while also cutting down initial building expenses. Municipalities looking at their budgets find this particularly appealing since they spend less upfront money yet get roads that require fewer repairs later on. The payoff comes in both reduced maintenance costs and smoother driving experiences for everyone who uses those roads day after day.

Long-Term Maintenance Cost Reductions

Using fiberglass geogrids during road construction can cut down on maintenance costs over time, with some estimates showing savings of around 40%. These grids reinforce the road surface so repairs happen later than they would otherwise, which saves money for city coffers and construction companies alike. Looking at real world examples from different states shows that what seems like a bigger upfront expense actually pays off through lower yearly maintenance bills. The fact that roads need fixing less often makes fiberglass geogrids pretty cost effective in the big picture. They offer quick cash savings right away while still providing financial peace of mind for years to come when it comes to keeping our roads in good shape.

Key Applications of Fiberglass Geogrid in Infrastructure

Roadway and Highway Reinforcement Solutions

Fiberglass geogrids are now pretty much standard equipment for building and reinforcing roads, especially major highways, because they really boost how stable the whole structure stays. These grids are super light yet incredibly strong, which means engineers can install them almost anywhere without too much trouble. Transportation crews love this since it cuts down on both time and effort compared to older methods. Take mountainous regions for instance, where getting heavy materials to remote construction sites was always a headache. Studies back up what we see in practice too there's evidence showing roads reinforced with fiberglass experience about half as much deformation over time. The upside? Safer driving conditions obviously, but also road surfaces that last way longer between repairs, saving taxpayers money in the long run.

Slope Stabilization for Erosion Control

When dealing with hills and mountains, geogrids really help keep slopes stable so we don't get erosion problems or landslides. These fiberglass grids actually lock into place within the soil itself, giving extra strength to the ground below. They make compacting easier too, which helps maintain better soil structure overall. Some real world tests have shown that using these grids can cut down on erosion by around 70%, sometimes even more depending on conditions. That kind of improvement makes erosion control much more efficient for engineers working on these projects. Plus it saves money while protecting our environment from damage over time.

Geo Grid Applications in Retaining Walls

Using fiberglass geogrids when building retaining walls really increases how much weight they can hold and makes them last longer. Traditional approaches just don't compare since these grids allow for taller walls that stay strong without falling apart. Engineers have actually tested this stuff and found something pretty impressive fiberglass reinforced walls tend to last about 40% longer before problems start showing up. For civil engineers working on infrastructure projects, this means fewer repairs down the road. The walls built with geogrids keep standing firm even after years of exposure to weather extremes and heavy traffic loads, which saves money in maintenance costs over time.

Airport Runway and Heavy Traffic Zone Support

Airports need really tough materials for their runways and areas where lots of vehicles pass through regularly. Fiberglass geogrids work great here because they hold up so well against cracks forming when roads get stressed from all that weight. Airport managers have noticed something interesting too. After putting these grids into place, there were fewer problems with runways breaking down. Some places saw around a third less failures actually. The bottom line is stronger, safer airports that keep working even after years of planes taking off and landing plus whatever weather comes along.

Fiberglass Geogrid vs. Traditional Road Reinforcement Materials

Comparative Analysis: Geogrid vs. Steel Mesh

The ongoing discussion about fiberglass geogrids versus steel mesh for reinforcing roads really hinges on two main factors: how heavy they are and how bendy they can get. Fiberglass products weigh way less than their steel counterparts, something contractors notice immediately during transport and setup. Plus, these geogrids flex better under stress, so they handle ground movements much better than stiff steel grids that tend to crack when things shift around. Some field tests back this up too showing fiberglass actually reduces road cracks by around 30% compared to old school steel solutions. Over time, this means longer lasting roads with fewer repairs needed down the line.

Advantages Over Geotextile Fabrics

When it comes to reinforcing roads, fiberglass geogrids actually offer several key benefits compared to traditional geotextile fabrics. They work really well at spreading out loads across surfaces and keeping soils stable during construction. These grids last much longer too, even when exposed to extreme weather conditions that would break down other materials. The UV resistance factor alone makes them stand out from competitors on the market today. Most civil engineers we talk to tend to favor geogrid solutions because they know how these products perform year after year without needing replacement. What's more important for infrastructure projects? Well, fiberglass keeps its strength intact over time while resisting corrosion better than almost any alternative available right now. That kind of reliability matters a lot when building something meant to last decades rather than just a few years.

Performance in Extreme Weather Conditions

Fiberglass geogrids really stand out when it comes to holding up against harsh weather compared to older materials. Traditional stuff just doesn't cut it anymore when temperatures swing wildly or storms hit hard. Research shows that roadways using fiberglass reinforcement tend to last much longer without cracking or breaking down in areas where weather goes from bad to worse quickly. Engineers love seeing how well these grids perform even when moisture levels are high or there are constant freeze-thaw cycles throughout the seasons. Infrastructure built with this material can actually handle what Mother Nature throws at it far better than most alternatives, which means fewer repairs and longer lasting projects for communities everywhere.

Installation Guidelines for Optimal Geogrid Performance

Surface Preparation and Tensioning Techniques

Getting the surface ready right matters a lot for how well fiberglass geogrids work over time and distribute weight properly. When installing these grids, it helps if the ground beneath them is free from debris, levelled out, and properly compacted. This basic step stops those annoying buckles from forming later on and gives the geogrid something solid to sit on. After getting the base sorted, applying tension correctly becomes really important too. If done wrong, parts might buckle early or not spread weight evenly across the whole area. Industry folks have noticed something interesting - when people follow proper installation guides, they often see better results, sometimes up to 25% improvement in performance. The trick here is making sure everything is pulled tight enough so there aren't any wrinkles or folds in the grid material. A smooth, wrinkle-free installation just works better when reinforcing structures long term.

Integrating Geo Mesh with Asphalt Layers

When combining fiberglass geogrids with asphalt surfaces, knowing how these materials work together makes all the difference for getting good results. The main approach usually starts with placing the geogrid underneath a fresh layer of hot mix asphalt. This setup helps cut down on those annoying cracks that reflect through from below. Real world tests show time and again that this combination does more than just last longer it actually makes roads perform better overall. The geogrid adds extra strength against stretching forces while spreading out vehicle weight across wider areas. For places where roads tend to crack easily, especially near intersections or heavy traffic zones, this technique provides solid protection against breakdowns in road structure. Many municipalities have adopted this practice because it saves money in the long run despite higher initial costs.

Quality Control Measures During Implementation

Getting good results from geogrid installations means putting in place solid quality checks throughout the whole process. Regular site visits help catch small problems early on before they turn into bigger headaches down the road, which keeps things running smoothly and lasts longer too. Companies that form dedicated QA teams often see better outcomes from their work. These specialized groups make sure everything gets done according to plan specifications, keep an eye on how tight the grids need to be stretched, and check if ground surfaces meet requirements both before starting and once finished. Some studies suggest these teams might boost project success rates somewhere around 30 percent, though actual improvements depend heavily on specific site conditions and worker experience levels.