วิธีที่แผ่นใยแก้วเสริมดินเพิ่มความทนทานและความคุ้มค่าของถนน

กลไกของการกระจายแรงและการป้องกันรอยแตกร้าว

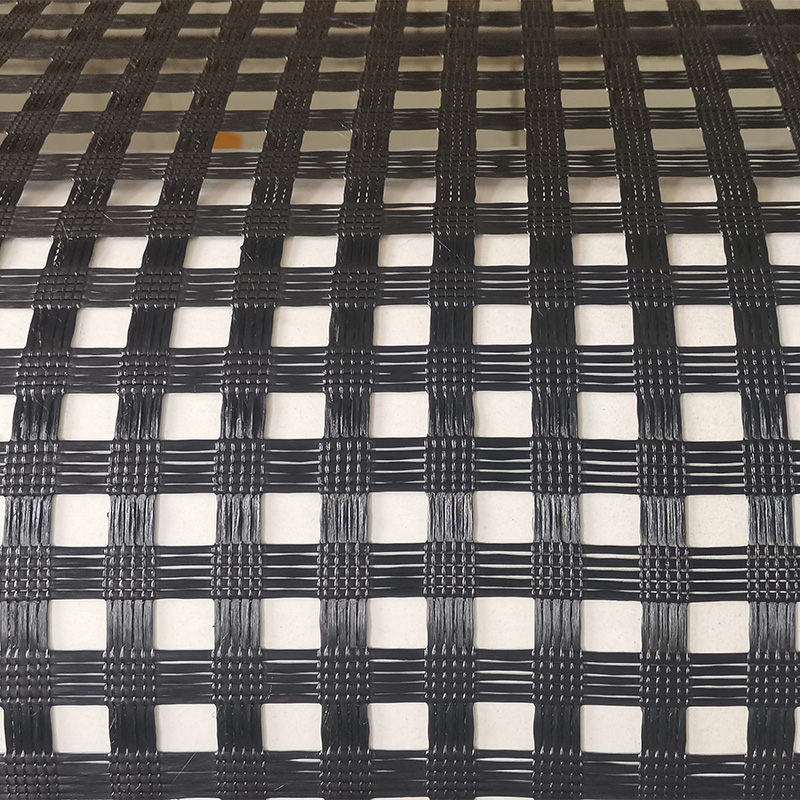

ตาข่ายไฟเบอร์กลาสช่วยยืดอายุการใช้งานของถนน เนื่องจากช่วยกระจายแรงกดน้ำหนักไปยังพื้นที่ที่กว้างขึ้น ซึ่งจะช่วยลดจุดที่เกิดแรงเครียดจนนำไปสู่การแตกร้าว เมื่อถนนต้องรับน้ำหนักจากบรรทุกขนาดใหญ่ซ้ำๆ ทุกวัน การกระจายแรงในลักษณะนี้มีความสำคัญอย่างมากในการรักษาความสมบูรณ์ของผิวถนน ข้อดีของไฟเบอร์กลาสคือความแข็งแรงเมื่อถูกดึง ดังนั้นแม้มีแรงภายนอกพยายามทำให้เกิดการบิดงอ ตาข่ายก็ยังคงมั่นคงและป้องกันไม่ให้ผิวแอสฟัลต์เกิดการบวมพอง งานวิจัยบางชิ้นแสดงให้เห็นว่าตาข่ายชนิดนี้สามารถลดการเกิดรอยร้าวสะท้อน (Reflective Cracking) บนผิวแอสฟัลต์ได้ประมาณร้อยละ 30 โดยประมาณ ซึ่งหมายถึงประสิทธิภาพที่ดีขึ้นโดยรวมของชั้นผิวถนน จากประสบการณ์จริง ผู้สร้างถนนพบว่าการใช้ตาข่ายไฟเบอร์กลาสในโครงการก่อสร้างช่วยให้ถนนอยู่ในสภาพดีเป็นเวลานาน และยังช่วยประหยัดค่าใช้จ่ายในการบำรุงรักษาในระยะยาวอีกด้วย

ขยายอายุการใช้งานของผิวทางด้วยการเสริมแรง

การเพิ่มตาข่ายไฟเบอร์กลาสลงในงานก่อสร้างถนนนั้น ทำให้ถนนมีอายุการใช้งานยาวนานกว่าพื้นผิวทั่วไปที่ไม่ได้ใช้วัสดุเหล่านี้ บางครั้งสามารถยืดอายุการใช้งานได้ถึงสองเท่า เมื่อเทียบกับผลการทดสอบภาคสนาม งานวิจัยพบว่าถนนที่ได้รับการเสริมความแข็งแรงนี้สามารถต้านทานการแตกร้าวและหลุมบ่อที่เกิดจากแรงกดซ้ำๆ ของยานพาหนะได้ดีกว่า ในแง่ของความยั่งยืน การประเมินวงรอบชีวิต (Life Cycle Assessment) แสดงให้เห็นว่าการใช้วัสดุไฟเบอร์กลาสนั้นให้ประสิทธิภาพที่ดีขึ้นในทุกปี พร้อมทั้งลดค่าใช้จ่ายในการก่อสร้างในช่วงแรกด้วย องค์กรท้องถิ่นที่ต้องคำนึงถึงงบประมาณมักพบว่าวิธีการนี้น่าสนใจเป็นพิเศษ เนื่องจากสามารถลดค่าใช้จ่ายเริ่มต้นได้ แต่ยังคงได้รับถนนที่ต้องการการซ่อมแซมที่น้อยกว่าในระยะยาว ผลตอบแทนที่ได้คือทั้งค่าใช้จ่ายในการบำรุงรักษาน้อยลง และประสบการณ์การขับขี่ที่ราบรื่นขึ้นสำหรับผู้ที่ใช้ถนนเหล่านี้ในชีวิตประจำวัน

การลดต้นทุนการบำรุงรักษาในระยะยาว

การใช้ตาข่ายใยแก้วสำหรับงานก่อสร้างถนนสามารถช่วยลดค่าใช้จ่ายในการบำรุงรักษาในระยะยาวได้ โดยมีการประมาณการณ์ไว้ว่าสามารถประหยัดได้ประมาณ 40% ตาข่ายเหล่านี้จะช่วยเสริมความแข็งแรงให้กับผิวถนน ทำให้การซ่อมแซมเกิดขึ้นภายหลังจากที่ควรจะต้องซ่อมแซมตามปกติ ซึ่งจะช่วยประหยัดค่าใช้จ่ายทั้งสำหรับเมืองและบริษัทก่อสร้าง ดูจากตัวอย่างในโลกจริงของแต่ละรัฐแล้ว จะพบว่าแม้ค่าใช้จ่ายในระยะแรกดูเหมือนจะสูงกว่า แต่กลับให้ผลตอบแทนที่ดีในรูปแบบของค่าบำรุงรักษาที่ลดลงในแต่ละปี ความจริงที่ว่าถนนจำเป็นต้องซ่อมแซมน้อยลงนั้น ทำให้ตาข่ายใยแก้วมีความคุ้มค่าทางเศรษฐกิจในภาพรวม พวกมันสามารถประหยัดเงินได้ทันทีตั้งแต่แรกเริ่ม และยังคงให้ความอุ่นใจทางการเงินไปอีกหลายปีในอนาคต เมื่อพิจารณาถึงการรักษาสภาพถนนให้อยู่ในสภาพที่ดี

การประยุกต์ใช้งานหลักของไฟเบอร์กลาสจีโอกริดในโครงสร้างพื้นฐาน

โซลูชันการเสริมแรงถนนและทางหลวง

ตาข่ายใยแก้วนำไฟเบอร์ที่ใช้ในงานก่อสร้างและเสริมความแข็งแรงของถนน โดยเฉพาะทางหลวงสายหลักนั้น ปัจจุบันถือเป็นอุปกรณ์มาตรฐานกันอย่างแพร่หลาย เนื่องจากช่วยเพิ่มความมั่นคงของโครงสร้างถนนได้อย่างมีประสิทธิภาพ ตาข่ายชนิดนี้มีน้ำหนักเบาแต่แข็งแรงมาก ซึ่งหมายความว่าวิศวกรสามารถติดตั้งได้เกือบทุกที่โดยไม่ต้องพบเจอกับความยุ่งยากมากนัก เจ้าหน้าที่งานขนส่งชื่นชอบวัสดุชนิดนี้เพราะช่วยลดเวลาและแรงงานเมื่อเทียบกับวิธีการเก่าๆ ตัวอย่างเช่น ในเขตภูเขา ที่เคยมีปัญหาในการลำเลียงวัสดุหนักๆ ไปยังพื้นที่ก่อสร้างที่อยู่ห่างไกล งานวิจัยต่างๆ ก็สนับสนุนสิ่งที่เห็นในทางปฏิบัติจริงเช่นกัน โดยมีหลักฐานแสดงให้เห็นว่าถนนที่เสริมด้วยใยแก้วไฟเบอร์นั้น มีการบิดตัวเพียงแค่ครึ่งเดียวเมื่อเทียบกับถนนแบบเดิม ข้อดีที่ได้คือ ช่วยให้การขับขี่ปลอดภัยมากยิ่งขึ้น และผิวถนนมีอายุการใช้งานยาวนานขึ้นระหว่างการซ่อมบำรุง ซึ่งช่วยประหยัดงบประมาณของผู้เสียภาษีในระยะยาว

การเสริมความมั่นคงของความลาดชันสำหรับการควบคุมการกัดเซาะ

เมื่อต้องรับมือกับเนินเขาและภูเขา ตาข่ายเพื่อการก่อสร้างทางภูมิศาสตร์ช่วยยึดโครงสร้างของลาดชันให้มีเสถียรภาพมากขึ้น เพื่อป้องกันปัญหาการกัดเซาะดินหรือดินถล่ม ตาข่ายไฟเบอร์กลาสเหล่านี้จะยึดติดเข้ากับดินโดยตรง ทำให้พื้นดินชั้นล่างมีความแข็งแรงมากยิ่งขึ้น นอกจากนี้ยังช่วยให้การอัดดินทำได้ง่ายขึ้น ซึ่งส่งผลให้โครงสร้างโดยรวมของดินมีความสมบูรณ์มากขึ้น จากการทดสอบจริง พบว่าการใช้ตาข่ายเหล่านี้สามารถลดการกัดเซาะได้ประมาณ 70% หรือมากกว่านั้นในบางสภาวะ ระดับการปรับปรุงเช่นนี้ทำให้วิศวกรสามารถควบคุมการกัดเซาะได้อย่างมีประสิทธิภาพมากยิ่งขึ้น ยิ่งไปกว่านั้นยังช่วยประหยัดค่าใช้จ่ายและปกป้องสิ่งแวดล้อมจากการเสียหายในระยะยาวอีกด้วย

การใช้งานจีโอกริดในกำแพงกันดิน

การใช้ตาข่ายใยแก้วไฟเบอร์กลาสในการก่อสร้างกำแพงกันดินนั้น ช่วยเพิ่มความสามารถในการรับน้ำหนักและยืดอายุการใช้งานของกำแพงได้อย่างชัดเจน เมื่อเทียบกับวิธีการแบบดั้งเดิม ซึ่งไม่สามารถสร้างกำแพงที่สูงแต่ยังคงความแข็งแรงทนทานได้เหมือนกับวิธีนี้ วิศวกรผู้ทำการทดสอบได้พบข้อเท็จจริงที่น่าประทับใจประการหนึ่ง คือ กำแพงที่เสริมด้วยไฟเบอร์กลาสนั้นมีอายุการใช้งานยาวนานกว่าประมาณ 40% ก่อนที่จะเริ่มเกิดปัญหาต่าง ๆ สำหรับวิศวกรโยธาที่ทำงานด้านโครงสร้างพื้นฐาน หมายความว่าจะมีค่าซ่อมแซมที่ลดลงในระยะยาว กำแพงที่สร้างด้วยตาข่าย geogrid ยังคงความแข็งแรงทนทานแม้ผ่านการใช้งานมานานหลายปี ไม่ว่าจะเป็นสภาพอากาศที่เลวร้ายหรือรับน้ำหนักจราจรที่เข้มข้น ซึ่งช่วยประหยัดค่าใช้จ่ายในการบำรุงรักษาในระยะยาว

การสนับสนุนพื้นวิ่งสนามบินและเขตการจราจรหนัก

สนามบินต้องการวัสดุที่มีความทนทานเป็นพิเศษสำหรับทางวิ่งและพื้นที่ที่มียานพาหนะผ่านเป็นประจำ เทคโนโลยีตาข่ายเสริมใยแก้ว (Fiberglass geogrids) ใช้งานได้ดีมากในบริเวณเหล่านี้ เนื่องจากสามารถป้องกันการแตกร้าวของพื้นถนนที่เกิดจากแรงกดทับของน้ำหนักได้อย่างมีประสิทธิภาพ ผู้จัดการสนามบินยังได้สังเกตเห็นสิ่งที่น่าสนใจอีกด้วย หลังจากติดตั้งตาข่ายเหล่านี้แล้ว พบว่ามีปัญหาการพังทลายของทางวิ่งลดลง โดยบางพื้นที่มีอัตราการเกิดปัญหาลดลงราวหนึ่งในสาม สรุปได้ว่าสนามบินมีความแข็งแรงและปลอดภัยมากยิ่งขึ้น สามารถใช้งานได้อย่างต่อเนื่องแม้ผ่านการบินขึ้น-ลงของเครื่องบินตลอดหลายปี และสภาพอากาศที่เปลี่ยนแปลงไป

ไฟเบอร์กลาสจีโอกริดเทียบกับวัสดุเสริมแรงถนนแบบดั้งเดิม

การวิเคราะห์เปรียบเทียบ: จีโอกริดเทียบกับตาข่ายเหล็ก

การอภิปรายที่ยังคงดำเนินอยู่เกี่ยวกับการใช้ตาข่ายเสริมแรงแบบไฟเบอร์กลาสแทนเหล็กเส้นในงานก่อสร้างถนนนั้น แท้จริงแล้วขึ้นอยู่กับสองปัจจัยหลัก คือ น้ำหนักของวัสดุและความสามารถในการงอตัวได้ ผลิตภัณฑ์ที่ทำจากไฟเบอร์กลาสมีน้ำหนักเบากว่าเหล็กมาก ซึ่งผู้รับเหมาสามารถรับรู้ได้ทันทีในระหว่างการขนส่งและการติดตั้ง นอกจากนี้ ตาข่ายเสริมแรงชนิดนี้ยังสามารถยืดหยุ่นได้ดีกว่าเมื่ออยู่ภายใต้แรงกดดัน จึงสามารถรองรับการเคลื่อนตัวของพื้นดินได้ดีกว่าเหล็กเส้นแบบดั้งเดิมที่มักจะแตกหักเมื่อมีการเคลื่อนตัวเกิดขึ้น มีการทดสอบภาคสนามบางส่วนยืนยันเรื่องนี้เช่นกัน โดยพบว่าไฟเบอร์กลาสนั้นสามารถลดการเกิดรอยร้าวบนถนนได้มากถึงประมาณร้อยละ 30 เมื่อเทียบกับวิธีการแบบเหล็กดั้งเดิม ด้วยเหตุนี้จึงทำให้ถนนมีอายุการใช้งานที่ยาวนานขึ้น และลดความจำเป็นในการซ่อมแซมในระยะยาว

ข้อได้เปรียบเหนือผ้าทางเทคนิค

เมื่อพูดถึงการเสริมความแข็งแรงให้ถนน ตาข่ายโพลีเมอร์ใยแก้ว (fiberglass geogrids) นั้นมีจุดเด่นที่สำคัญหลายประการเมื่อเทียบกับผ้าใยสังเคราะห์ (geotextile fabrics) แบบดั้งเดิม ตัวตาข่ายสามารถช่วยกระจายแรงกดทับบนพื้นผิวและรักษาความมั่นคงของดินขณะก่อสร้างได้เป็นอย่างดี อีกทั้งยังมีอายุการใช้งานยาวนานกว่า โดยสามารถทนต่อสภาพอากาศที่เลวร้ายซึ่งอาจทำให้วัสดุอื่นเสื่อมสภาพได้ เพียงเรื่องความต้านทานรังสี UV ก็ทำให้ตาข่ายชนิดนี้โดดเด่นกว่าผลิตภัณฑ์คู่แข่งในตลาดปัจจุบัน วิศวกรงานก่อสร้างส่วนใหญ่ที่เราได้พูดคุยด้วย มักให้ความชอบใจกับทางแก้ปัญหาโดยใช้ตาข่ายเสริมดิน (geogrid) เพราะพวกเขารู้ดีว่าผลิตภัณฑ์เหล่านี้ทำงานได้ดีต่อเนื่องหลายปีโดยไม่จำเป็นต้องเปลี่ยนใหม่ สิ่งที่สำคัญยิ่งกว่าสำหรับโครงการโครงสร้างพื้นฐาน? ใยแก้วสามารถรักษาความแข็งแรงไว้ได้ตลอดเวลา และทนต่อการกัดกร่อนได้ดีกว่าวัสดุทดแทนอื่น ๆ แทบทุกชนิดที่มีอยู่ในปัจจุบัน ความน่าเชื่อถือในระดับนี้มีความสำคัญอย่างมากเมื่อคุณกำลังสร้างสิ่งที่ออกแบบมาให้อยู่ได้นานเป็นสิบ ๆ ปี ไม่ใช่เพียงแค่ไม่กี่ปีเท่านั้น

ประสิทธิภาพในสภาพอากาศสุดขั้ว

แผ่นตาข่ายไฟเบอร์กลาสสำหรับงานก่อสร้างนั้นมีความโดดเด่นอย่างมากเมื่อเทียบกับวัสดุรุ่นเก่าในการรับมือกับสภาพอากาศที่เลวร้าย อุณหภูมิที่เปลี่ยนแปลงอย่างรุนแรงหรือพายุที่กระหน่ำซัดเข้ามา วัสดุแบบดั้งเดิมไม่สามารถรองรับได้อย่างมีประสิทธิภาพเหมือนเมื่อก่อนอีกต่อไป การศึกษาแสดงให้เห็นว่าถนนที่ใช้ไฟเบอร์กลาสเสริมความแข็งแรงนั้นมีอายุการใช้งานที่ยาวนานกว่ามาก โดยไม่เกิดรอยร้าวหรือการเสื่อมสภาพในพื้นที่ที่สภาพอากาศเปลี่ยนแปลงอย่างรวดเร็ว วิศวกรมักชื่นชมในสมรรถนะของแผ่นตาข่ายเหล่านี้ที่ยังคงทำงานได้ดีแม้ในสภาวะที่มีความชื้นสูง หรือแม้จะต้องเผชิญกับวงจรการแช่แข็งและการละลายซ้ำๆ ในแต่ละฤดูกาล สิ่งก่อสร้างที่สร้างด้วยวัสดุนี้สามารถทนต่อสภาพธรรมชาติได้ดีกว่าทางเลือกอื่นๆ อย่างชัดเจน ซึ่งหมายความว่าชุมชนต่างๆ จะได้ประโยชน์จากโครงการที่มีความทนทานและต้องซ่อมแซมน้อยลง

แนวทางการติดตั้งสำหรับประสิทธิภาพจีโอกริดที่ดีที่สุด

เทคนิคการเตรียมพื้นผิวและการดึงตึง

การเตรียมพื้นผิวให้พร้อมอย่างถูกต้องนั้นมีความสำคัญมากต่อประสิทธิภาพของตาข่ายไฟเบอร์กลาสในระยะยาวและการกระจายแรงกดได้อย่างเหมาะสม ในการติดตั้งตาข่ายเหล่านี้ ควรเตรียมพื้นดินด้านล่างให้ปราศจากเศษวัสดุ ปรับระดับ และอัดแน่นให้เหมาะสม ขั้นตอนพื้นฐานนี้จะช่วยป้องกันปัญหาการบิดงอหรือย่นที่เกิดขึ้นภายหลัง และให้ฐานที่มั่นคงสำหรับวางตาข่าย เมื่อเตรียมฐานเสร็จแล้ว ขั้นตอนการดึงให้ตึงก็มีความสำคัญมากเช่นกัน หากทำได้ไม่ถูกต้อง อาจทำให้เกิดการบิดงอในช่วงแรก หรือการกระจายแรงไม่สม่ำเสมอทั่วทั้งพื้นที่ ผู้เชี่ยวชาญในอุตสาหกรรมสังเกตพบสิ่งที่น่าสนใจคือ เมื่อผู้ปฏิบัติงานทำตามคู่มือการติดตั้งอย่างถูกต้อง มักจะเห็นผลลัพธ์ที่ดีขึ้น บางครั้งมีประสิทธิภาพเพิ่มขึ้นถึง 25% วิธีการที่สำคัญคือ การดึงตาข่ายให้ตึงเพียงพอ เพื่อหลีกเลี่ยงรอยย่นหรือรอยพับในวัสดุตาข่าย การติดตั้งที่เรียบเนียนปราศจากรอยย่นนั้นจะให้ผลลัพธ์ที่ดีกว่าเมื่อใช้งานเพื่อเสริมโครงสร้างในระยะยาว

การรวม Geo Mesh กับชั้นยางมะตอย

เมื่อรวมตาข่ายไฟเบอร์กลาสกับพื้นผิวแอสฟัลต์ การเข้าใจว่าทั้งสองวัสดุนี้ทำงานร่วมกันอย่างไรนั้นมีความสำคัญอย่างมากต่อผลลัพธ์ที่ดี วิธีหลักมักเริ่มต้นด้วยการวางตาข่ายไว้ด้านล่างชั้นแอสฟัลต์ร้อนใหม่ ชุดการติดตั้งแบบนี้ช่วยลดรอยร้าวที่เกิดขึ้นและสะท้อนขึ้นมาจากด้านล่างได้อย่างมีประสิทธิภาพ ผลการทดสอบจากโลกแห่งความเป็นจริงแสดงให้เห็นซ้ำแล้วซ้ำอีกว่าการรวมกันนี้ไม่เพียงแต่ทำให้ถนนมีอายุการใช้งานยาวนานขึ้น แต่ยังช่วยเพิ่มประสิทธิภาพโดยรวมของถนนด้วย ตาข่ายช่วยเพิ่มความแข็งแรงพิเศษต่อแรงดึงและกระจายแรงกดทับจากยานพาหนะให้ทั่วพื้นที่กว้างขึ้น สำหรับพื้นที่ที่ถนนมักเกิดรอยร้าวง่าย โดยเฉพาะบริเวณทางแยกหรือเขตที่มีการจราจรหนาแน่น วิธีนี้ให้การป้องกันโครงสร้างถนนเสื่อมสภาพอย่างแข็งแกร่ง มีหลายเทศบาลนำวิธีการนี้ไปใช้เพราะช่วยประหยัดค่าใช้จ่ายในระยะยาว แม้จะมีต้นทุนเริ่มต้นสูงกว่า

มาตรการควบคุมคุณภาพระหว่างการดำเนินงาน

การได้ผลลัพธ์ที่ดีจากการติดตั้งตาข่ายเพิ่มความแข็งแรงของดิน (geogrid) หมายถึงการมีการตรวจสอบคุณภาพที่เข้มงวดตลอดกระบวนการทั้งหมด การตรวจสถานที่อย่างสม่ำเสมอจะช่วยให้สามารถแก้ไขปัญหาเล็กๆ ได้ตั้งแต่แรกเริ่ม ก่อนที่ปัญหาเหล่านั้นจะลุกลามกลายเป็นปัญหาใหญ่ในระยะยาว ซึ่งจะช่วยให้การทำงานดำเนินไปอย่างราบรื่นและยังยืดอายุการใช้งานของโครงสร้างได้มากขึ้น บริษัทที่จัดตั้งทีมควบคุมคุณภาพ (QA) แบบเฉพาะกิจ มักจะได้ผลงานที่ออกมาดีกว่า ทีมงานเฉพาะทางเหล่านี้จะทำหน้าที่ตรวจสอบให้ทุกขั้นตอนดำเนินไปตามแบบแปลนที่กำหนดไว้ คอยควบคุมระดับแรงดึงของตาข่ายให้ถูกต้อง และตรวจสอบสภาพพื้นดินทั้งก่อนเริ่มต้นและเมื่อแล้วเสร็จ มีงานวิจัยบางส่วนชี้ให้เห็นว่าทีมงานลักษณะนี้อาจช่วยเพิ่มอัตราความสำเร็จของโครงการได้ราว 30 เปอร์เซ็นต์ แม้ว่าผลลัพธ์ที่แท้จริงจะขึ้นอยู่กับสภาพเฉพาะของพื้นที่และระดับประสบการณ์ของแรงงานเป็นสำคัญ