Understanding Pet Geogrid and Its Properties

Material Composition of Pet Geogrid

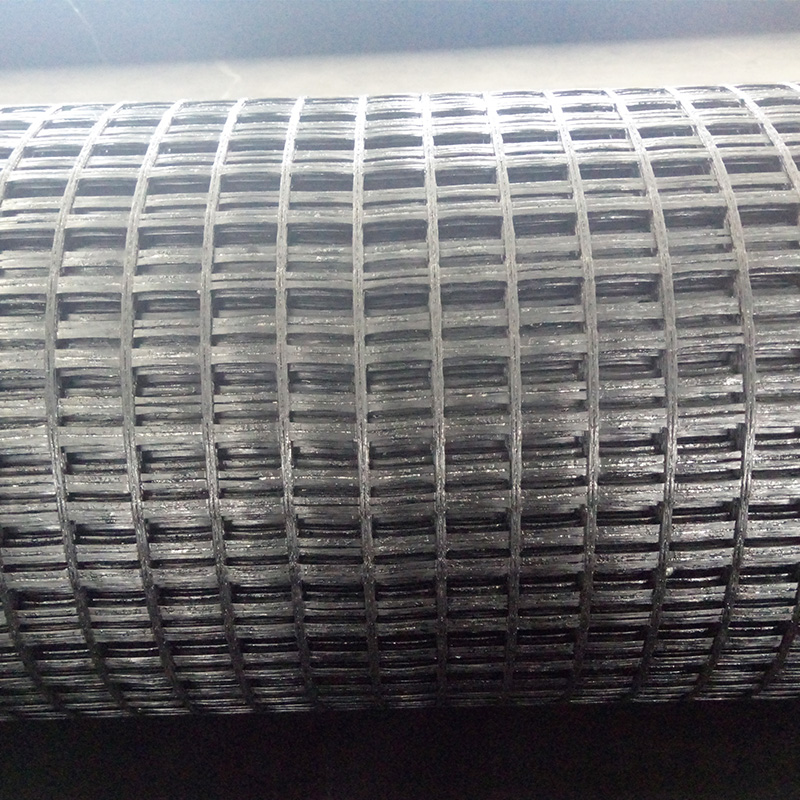

Pet Geogrid mainly consists of recycled polyester known as PET, which represents a green alternative for construction work. Choosing this material helps support sustainable practices while keeping the geogrid strong enough for real world applications. When manufacturers blend in some high density polyethylene HDPE, they actually improve how well the product stands up against sunlight damage and chemicals, so it works great even when exposed to harsh environments outside. Knowing all this explains why engineers keep turning to Pet Geogrid for their projects these days. The stuff lasts longer than many alternatives and performs reliably whether installed in hot desert climates or cold northern regions where freeze thaw cycles would normally cause problems for lesser materials.

Key Features: High Tensile Strength and Durability

The Pet Geogrid comes packed with some seriously impressive specs, especially when it comes to tensile strength that sits somewhere between 20 and 50 kN/m. This kind of strength makes all the difference in projects where things need to hold up under heavy loads. What really stands out is how this strength translates into reliable performance for slope reinforcement and soil stabilization work that lasts years instead of months. Maintenance crews will appreciate not having to constantly check on these installations since they tend to stay put without much fuss. Another big plus point is the material's durability factor. Unlike many traditional alternatives, Pet Geogrid doesn't degrade quickly even after prolonged exposure to harsh conditions. Contractors working on roadways, retaining walls, or any sort of earthworks have found this product to be consistently effective across different types of ground materials. For anyone looking at long term solutions without breaking the bank on replacements, this stuff has proven itself time and again in real world applications.

Comparison to Traditional Geo Grid Materials

When looking at traditional geogrid materials made mostly from polypropylene, Pet Geogrid stands out because it can actually be recycled multiple times. Tests show that Pet Geogrid usually beats out older materials when it comes to holding up under tension and working well in different weather situations. What makes this material even better is that while it might cost a bit more upfront, the money saved over time through durability means projects end up cheaper in the long run. Construction companies are starting to notice these advantages, especially as regulations get stricter about what counts as eco-friendly construction. Choosing Pet Geogrid isn't just good for the environment though it also meets all the technical requirements needed for serious infrastructure work today.

Mechanics of Slope Stabilization Using Geogrid Fabric

Soil Reinforcement Principles

Using geogrid fabric to reinforce soil significantly boosts its ability to carry weight, which makes this method essential for stabilizing slopes. When we embed geogrid layers into the ground, they spread out the pressure points across a wider area, leading to better stability and less sinking over time. The way geogrid works is pretty straightforward actually - it locks together with the surrounding earth to create kind of a hidden framework inside the soil itself. For engineers working on different projects, grasping how geogrid functions helps them design better solutions tailored specifically for sites with challenging terrain or unstable ground conditions.

Interlocking Mechanism with Geogrid Wall Structures

Pet Geogrid's interlocking design forms a strong 3D grid that really boosts wall stability through increased shear resistance. The system handles weight from all directions, making it great for those tricky slope projects where instability is always a concern. Field tests show these grids cut down on landslide risks and stop soil from sliding away, particularly important on steep hillsides. Contractors love them because they offer solid support while keeping costs under control compared to traditional methods. Many civil engineers now specify Pet Geogrid for retaining walls and embankments where long term performance matters most.

Preventing Surface Erosion and Soil Slippage

Pet Geogrid is really effective at stopping surface erosion and keeping soil from slipping away. When installed properly, it holds the soil in place and actually encourages plant growth. These plants then help hold everything together even better, making the whole area much more stable against weather impacts. Managing surface water runoff becomes easier too, since the geogrid system naturally handles those tricky hydrological issues that often lead to soil problems. Research shows pretty impressive results when using Pet Geogrid - some tests found erosion reductions of around 70% in areas prone to these issues. For landowners dealing with unstable ground conditions, this represents a solid long term investment in maintaining healthy soil structures without constant maintenance headaches.

Installation Techniques for Optimal Performance

Site Preparation and Grading Best Practices

Getting the site ready properly makes all the difference when it comes to getting good results from geogrid installations. First things first, the ground needs proper grading and compaction work so there's solid support underneath where the geogrid goes. Before starting any actual installation, take time to check out the soil conditions thoroughly. Make sure the area is completely dry and clear of any dirt or rocks that might get in the way later on. When this groundwork gets done right, it cuts down on headaches during installation and helps the whole geogrid system last longer without issues. Following these steps leads to smoother installation overall and keeps the geogrid working as intended for years to come.

Step-by-Step Pet Geogrid Layering Process

Layering geogrid properly needs some planning if we want good structural results. First things first, the geogrid has to go into the soil at just the right spot where it can really grab hold and give that extra stability everyone is looking for. Most folks start by putting down the first layer of geogrid material, then pack the surrounding soil tightly around it so nothing shifts during construction. When adding more layers on top, make sure they overlap enough to create that continuous support system across the entire area. And don't forget about the last part either - backfilling carefully is crucial to keep everything positioned correctly without damaging those hardworking geogrid layers. Following this kind of step-by-step method not only makes the job go smoother but also gets the most out of what geogrid technology can offer for long term structural strength.

Anchoring Methods for Steep Slopes

When working on steep slopes, proper anchoring becomes absolutely essential for keeping geogrids from slipping and maintaining soil stability. Most engineers rely on soil nails or rock anchors to secure everything in place, giving the system enough grip against potential movement. Some projects also combine geogrids with geotextiles for extra strength where needed. The terrain itself plays a big role here too. Different landscapes require different approaches to anchoring, so taking time to study site conditions helps pick the right solutions. This careful planning makes all the difference in preventing failures down the road. Real world experience shows that these techniques work remarkably well, providing long lasting support across difficult hillside environments without constant maintenance headaches.

Real-World Applications and Cost Considerations

Case Study: Saint Mark School Slope Restoration

Saint Mark School's recent work on their campus slopes stands out as a great example of how Pet Geogrid can be used in fixing unstable ground areas. After installation, we noticed significant improvements in keeping the slopes stable while cutting down on how often they needed repairs. The geogrid really helped control erosion problems and reduced water runoff from the hillsides, making the whole area around the school much safer for students and staff alike. What makes this project interesting is that other schools dealing with similar terrain issues could follow this approach successfully. Schools across different regions have already started looking at implementing similar solutions after seeing what happened at Saint Mark, where both safety concerns and long term maintenance costs were addressed through proper slope stabilization techniques.

Balancing Geogrid Price with Project Longevity

When looking at whether to invest in Pet Geogrid, it makes sense to weigh what we spend upfront against how long it will last and what kind of maintenance it needs down the road. Sure, the price tag looks bigger compared to regular materials at first glance, but think about this: these grids tend to stick around much longer without needing replacement or fixes, which actually saves money over time. Anyone managing construction projects should really factor in their return on investment before picking materials. Experience shows that going with Pet Geogrid often pays off big time both financially and operationally throughout the entire lifespan of whatever gets built with it.

Sustainability Benefits in Infrastructure Projects

Using PET based geogrids in infrastructure work brings real environmental advantages. These materials cut down on what ends up in landfills while also making the overall carbon footprint better than traditional options. Most importantly, they fit right in with green building standards that many regions are now pushing for. Research shows that when builders switch to Pet Geogrid, carbon emissions drop quite a bit during construction projects. This matters because every ton less CO2 released helps protect our planet. With sustainability becoming increasingly important across the construction industry, Pet Geogrid stands out as something that works well both for the environment and for meeting actual engineering needs without compromising quality or safety.