Understanding Biaxial Geogrid: Structure and Function in Soil Stabilization

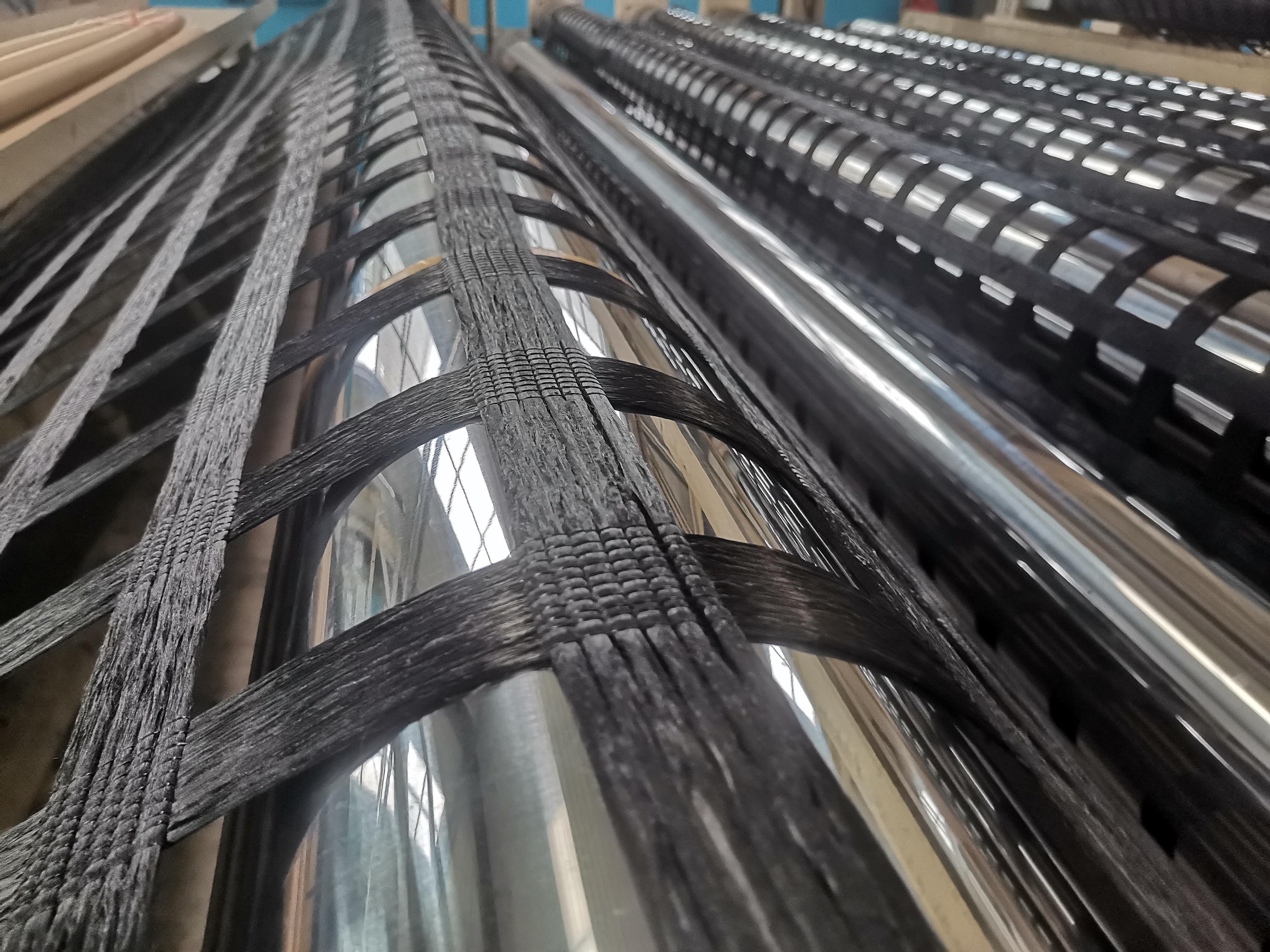

Biaxial geogrids are engineered polymer grids designed to reinforce soil and aggregate in two dimensions. Made from high-strength materials like polyester or polypropylene, their open grid structure features evenly spaced apertures that mechanically interlock with surrounding particles, limiting lateral movement while enhancing load distribution.

What Is Biaxial Geogrid and How Does It Work?

Biaxial geogrid works by forming what engineers call a mechanically stable layer inside soil or aggregate materials. The key thing about these grids is their strength goes both ways equally along length and width, which helps spread out stress from vehicles passing over or heavy structures sitting on top. When this happens, it takes pressure off those weaker spots in the ground beneath, making roads last much longer before they need fixing. Some actual field tests have found that roads built with biaxial geogrid require about 30 percent less maintenance work after five years when compared against similar roads without this reinforcement. That kind of difference adds up over time for transportation departments and construction companies alike.

Key Mechanical Properties That Enhance Construction Efficiency

Biaxial geogrids have impressive specs too, with tensile modulus ranging between 15 to 25 kN/m and junction efficiency above 90%. These materials really hold up when subjected to heavy weights without deforming. What makes them stand out is their ability to withstand both creep over time and chemical breakdown, which means they last much longer even in tough conditions. Construction projects see real benefits from using these grids. Timelines get shortened quite a bit sometimes by around 40% because there's less digging required and fewer imported materials needed. Take those road improvements in cities back in 2023 for instance, where engineers managed to cut down on aggregate usage by about 20% thanks to this technology.

The Role of Biaxial Geogrid in Improving Soil Stability and Load Distribution

Mechanisms Behind Load-Bearing Capacity Enhancement

Biaxial geogrid improves soil stability because it spreads out stress across its grid pattern, creating what engineers call a composite system with the surrounding dirt. The material has strong resistance to pulling forces in two directions at once, which means it can actually span over weaker spots in the ground below while keeping small rocks and gravel from moving around too much. What makes this type of reinforcement so effective is how it stops those concentrated pressure points that often lead to failures when there's no reinforcement present in regular soil conditions.

Interlocking Effect Between Soil and Biaxial Geogrid for Reduced Lateral Movement

When geogrid apertures engage with soil particles, they form something like a mechanical grip that resists shearing forces and reduces sideways movement. Tests show this kind of interaction can boost shear strength by around 40% over regular uncompacted soil, particularly noticeable in gravelly materials. The ribbed surface design actually adds another layer of friction, which helps keep earthworks standing firm even when water content is high. This makes all the difference for slope stability during heavy rains or after prolonged saturation periods.

Uniform Load Distribution Over Weak Subgrades

When biaxial geogrid spreads out those vertical forces across a wider area, it basically turns shaky ground into something that can actually hold weight reliably. For projects built on soft clay, this stuff cuts down on uneven settling problems by around 30 percent according to field tests. That means contractors can get away with using less gravel or stone in their base layers while still getting good results from the finished project. The real money saver comes into play for things like parking lot surfaces and storage areas for shipping containers. These places need constant support because vehicles keep driving over them day after day, and without proper reinforcement, they just end up cracking and buckling over time.

Biaxial Geogrid vs. Traditional Soil Stabilization Methods

When it comes to road building projects, biaxial geogrid stands out from alternatives like deep soil mixing or stone columns. We're talking about cutting down on materials by almost half and reducing digging depths by around 60%. That makes a huge difference in costs and environmental impact. Contractors who switch from traditional lime stabilization techniques to geogrid reinforcement typically finish their work about 22 days faster for every kilometer they build. And let's not forget the quality aspect either. The modular nature of geogrids gives engineers much better control over specifications than those unpredictable cement treated soil methods where results can vary quite a bit between batches and locations.

Real-World Applications: Road, Railway, and Infrastructure Projects

Highway Rehabilitation with Reduced Excavation and Material Use

In highway rehabilitation, biaxial geogrid stabilizes existing subgrades, reducing excavation depth by up to 50%. The grid laterally confines aggregate layers, allowing reuse of onsite soils and minimizing imported fill. A 2023 transportation study found integration of biaxial geogrid reduced base course thickness requirements by 30%, accelerating timelines and cutting material costs.

Railway Embankment Stabilization Under Heavy Cyclic Loads

Rail networks leverage biaxial geogrid’s ability to endure repetitive train-induced stresses. Its aperture geometry interlocks with ballast particles, reducing track settlement by 45% compared to untreated sections. This minimizes costly realignment cycles, particularly in areas with soft soils prone to lateral spreading and frequent maintenance.

Case Data: 40% Faster Construction on Urban Access Roads

Urban infrastructure projects have achieved 40% faster completion rates using biaxial geogrid. By eliminating deep soil replacement and enabling all-weather installation, crews completed 2-mile stretches in 12 days instead of 20. This efficiency supports rapid, low-disruption upgrades in congested city corridors.

Expanding Use Cases: Slope Stabilization and Retaining Structures

Eco-Friendly Slope Reinforcement with Minimal Site Disruption

When it comes to slope stabilization projects, biaxial geogrid stands out as an environmentally friendly solution because it cuts down on both excavation work and the need for heavy construction equipment. What makes this material so effective? Well, it has impressive tensile strength reaching around 40 kN per square meter combined with an aperture design that creates a strong soil matrix. Field tests have shown these grids can reduce erosion rates by approximately 60% when compared to traditional loose aggregate methods. Another big plus is how modular these geosynthetic systems are. Engineers can actually stabilize very steep slopes with gradients going up to about 70 degrees without disturbing existing plant life too much. This characteristic makes them particularly useful in places where ecological preservation matters most such as fragile coastal cliff areas or along riverbanks where maintaining natural habitats is critical.

Modular Retaining Systems Integrated with Biaxial Geogrid for Rapid Deployment

Putting up prefabricated retaining walls along with biaxial geogrid cuts down installation time by about half compared to regular concrete walls. We saw this firsthand during a big seismic reinforcement job back in California last year. What makes these geogrids so effective is how they spread out the sideways pressure from the earth across roughly 8 to 12 different soil layers. This helps buildings stand up better during earthquakes and when there's lots of rain falling. From a budget standpoint, these systems save around $18 to $22 on each square meter of wall. Even after ten years in areas where earthquakes happen regularly, tests show these structures keep about 99 percent of their original strength. That kind of durability makes them worth considering for any construction project facing tough ground conditions.

Maximizing Cost and Labor Efficiency in Biaxial Geogrid Installation

Streamlined Installation Process Reducing Onsite Labor Needs

Installation requires 40% less specialized labor than traditional stabilization techniques. Pre-cut rolls minimize handling time, reducing labor needs by up to 15%. Modular deployment allows crews to install 250–300 linear meters per day—three times the rate of woven geotextile alternatives.

Cost Savings Through Less Material and Shorter Project Timelines

Projects using biaxial geogrids achieve 50% reductions in aggregate layer thickness while maintaining equivalent load-bearing capacity. This translates to savings of $18–$22 per square meter in materials. Combined with 30% faster completion, overall project costs are reduced by 23% compared to conventional methods.

Best Practices for Quality Control During Deployment

Ensure 12–24 inches (300–600 mm) of overlap between geogrid sheets to maintain 95% seam integrity. Conduct tension tests every 50 meters using pull-out resistance gauges calibrated in 2.5 kN increments. Avoid installations during precipitation, as wet conditions increase the risk of lateral shifting by 15%, according to established geosynthetic engineering guidelines.

FAQ

What materials are biaxial geogrids made from?

Biaxial geogrids are typically made from high-strength materials such as polyester or polypropylene.

How do biaxial geogrids enhance soil stability?

Biaxial geogrids enhance soil stability by creating a mechanically stable layer that distributes stress and limits lateral movement in the soil.

What are the cost benefits of using biaxial geogrids?

Using biaxial geogrids can lead to significant cost savings due to reduced excavation, less material usage, and faster project timelines.

Are biaxial geogrids environmentally friendly?

Yes, biaxial geogrids are considered environmentally friendly as they reduce the need for heavy construction equipment and excavation work, preserving existing site conditions.

Table of Contents

- Understanding Biaxial Geogrid: Structure and Function in Soil Stabilization

- The Role of Biaxial Geogrid in Improving Soil Stability and Load Distribution

- Real-World Applications: Road, Railway, and Infrastructure Projects

- Expanding Use Cases: Slope Stabilization and Retaining Structures

- Maximizing Cost and Labor Efficiency in Biaxial Geogrid Installation

- FAQ