Understanding Polyester Geogrid Composition

Material Structure and Manufacturing Process

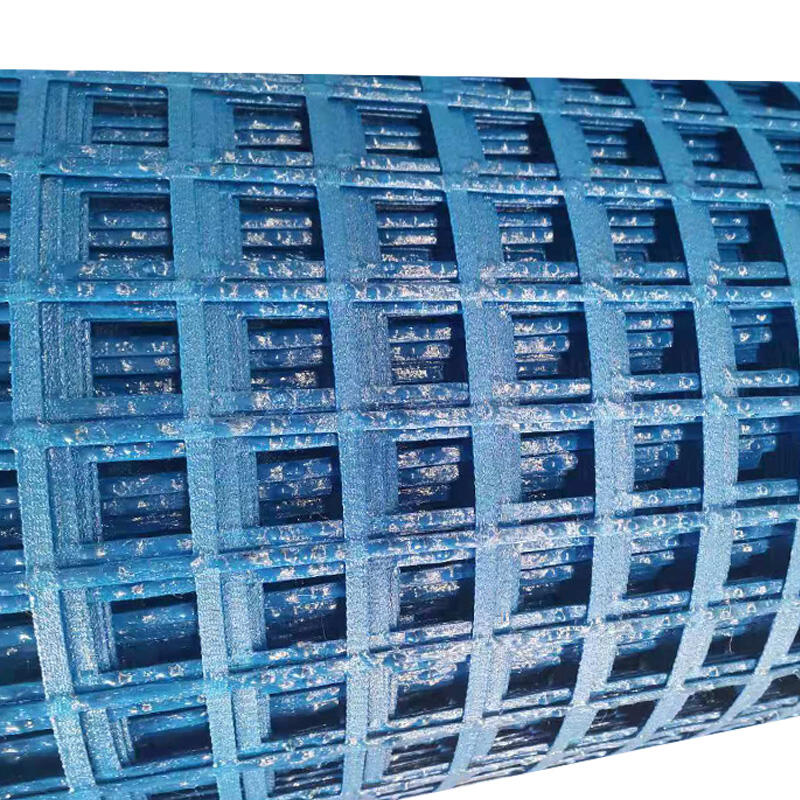

Most polyester geogrids consist mainly of those tough polyester fibers that stand up pretty well against environmental wear and tear while still maintaining some flexibility. What makes polyester so good for this application? Well, its polymer makeup gives these grids real strength under tension and they just don't break down easily over time. Engineers have found through testing that polyester's molecular arrangement actually helps it withstand pretty aggressive chemical conditions. That's why many construction projects rely on polyester geogrids when dealing with things like stabilizing loose soils or reinforcing weak ground areas where other materials might fail sooner rather than later.

Making polyester geogrids starts with extrusion and drawing methods that really boost their structural qualities. First off, during extrusion, the polyester gets heated until it melts, then it's formed into those distinctive grid shapes we see. After that comes the drawing stage where something interesting happens - the molecular chains line up properly, which makes the whole mesh much stronger and stiffer than before. What this means in practice is that these geogrids handle weight distribution pretty well and stay stable even when conditions change around them. Engineers have tested this stuff quite a bit over the years, especially looking at how different geosynthetic materials perform under stress.

Key Properties: Tensile Strength and Durability

The tensile strength of polyester geogrids plays a really important role when it comes to reinforcing soil structures. Basically, this measures how well the geogrid can handle pulling forces, which matters a lot when spreading out heavy weights across weak ground. Some tests have shown that certain polyester options can actually reach tensile strengths around 1,200 kN per meter. That kind of power makes these materials great choices for big infrastructure work such as building roads and supporting bridge foundations where stability is absolutely critical. Engineers often look at these numbers when deciding what materials will hold up best under different conditions.

Beyond just being strong under tension, polyester geogrids last longer because they can stand up to sunlight damage and chemicals found in soil and water. These materials keep working even after years outdoors where other products might degrade. Engineers know this from experience since many construction projects specify polyester geogrids precisely for their toughness. Take road building for instance the grids hold up against everything from acid rain to salt spray used on winter roads. Industry specs like ASTM D6408 back this up, making sure these materials meet strict requirements for lasting power when reinforcing earthworks and retaining walls.

Enhancing Load Distribution in Soil Layers

Polyester geogrids really help improve how weight spreads across different soil layers, which cuts down on spots where too much pressure builds up. The way they work actually makes the soil stronger overall, so embankments stay stable for longer periods. Basically, the grid spreads out whatever force gets applied, instead of letting heavy weights crush specific areas of soil. We've seen this happen in real world situations too. Road construction projects often show dramatic improvements when engineers include geogrids in their designs. The stress just doesn't concentrate anymore because the geogrid distributes everything more evenly throughout the ground. Soils mixed with these grids can handle much heavier traffic without breaking down compared to regular untreated soil, and we don't get those annoying little cracks forming at weak points either. That kind of consistent performance matters a lot for long term infrastructure maintenance.

Slope Stabilization with Geogrid Walls

Polyester geogrid walls play a critical role in stabilizing slopes and preventing failures that might otherwise cause serious structural problems. When installed correctly, these walls work by reinforcing the soil structure, making slopes much safer and longer lasting overall. Real world applications have demonstrated this effectiveness time and again. Take some highway projects for instance where geogrid installation cut down on slope failures while extending the lifespan of surrounding embankments. How it works? Contractors typically embed the geogrid material between soil layers during construction, taking into account factors like what kind of soil they're working with, how steep the slope is, and what kind of loads will be placed on the area. Good results come from careful planning though. Even with all the right specs, improper installation remains one of the biggest challenges engineers face when implementing geogrid solutions for slope stability.

Preventing Soil Erosion and Differential Settlement

Polyester geogrids fight soil erosion pretty well by strengthening weaker soils and keeping their structure intact, basically working as a protective layer against forces that wear away the ground. When installed properly, these grids actually lock into place with soil particles, stopping them from getting kicked around or washed away, so the soil stays put for much longer than it would otherwise. They do something else important too - they help tackle those annoying differential settlement problems. These happen when parts of the ground sink at different rates because some areas compress more than others under pressure. With geogrid reinforcement, engineers can manage these settlements better throughout construction sites, distributing stress more evenly while maintaining overall stability. Real world testing backs this up big time. Numerous field studies show明显 reductions in erosion rates and far fewer settlement issues compared to traditional methods, meaning structures built on reinforced soil last significantly longer without needing costly repairs down the road.

Cost-Effectiveness Compared to Concrete Solutions

When it comes to reinforcing concrete, polyester geogrids actually save money compared to older methods. Both the materials themselves and how they get installed tend to be cheaper options, which adds up big time on bigger construction jobs. Take Germany for instance where road repairs used these grids instead of regular concrete reinforcement techniques. The results? A real dent in overall expenses. Industry folks report that switching from concrete to geogrids can cut costs by around 30% in some cases. That kind of saving makes these grids pretty attractive for anyone watching their bottom line while still getting quality work done.

Long-Term Performance in Harsh Environments

Polyester geogrids stand up remarkably well against tough conditions, which is why they work so great for construction projects facing harsh weather. These grids keep their strength and function for years even when dealing with humidity, saltwater exposure, or chemical attacks from soil. Tests have shown these materials actually last much longer than what we typically see with older materials, plus they don't break down as easily over time. Real world data suggests most polyester geogrid installations stay effective anywhere from around 20 up to maybe 50 years without needing much upkeep at all. That kind of longevity beats out regular reinforcement methods by a wide margin when looking at how long things hold up and how resilient they remain through all sorts of environmental stressors.

Sustainability and Reduced Carbon Footprint

Polyester geogrids play a real role in making construction work greener overall. When builders choose these grids over regular concrete, they cut down on carbon emissions because they need less raw material and spend less energy moving stuff around. The polyester itself can actually be recycled too, so it fits into circular economy models where products don't just get thrown away after use. Some studies show that roads and other infrastructure built with geogrids might reduce carbon footprints by around 40 percent compared to traditional methods. This kind of reduction makes a big difference for engineers trying to build things that last while being kinder to the planet at the same time.

Road and Railway Embankment Construction

In road building and railway embankments, polyester geogrids really make a difference when it comes to keeping things stable and supported. Basically, these synthetic materials spread out the weight across the ground, which stops the earth from sinking down over time and makes the whole area stronger for what's built on top. Take the case of Germany's B91 federal highway where engineers faced serious subsidence problems because of old mines underneath the surface. They turned to geogrid technology and saw great results according to research published by NAUE. When looking at infrastructure projects generally, switching to geogrids means better performance overall. Real world data shows roads can handle heavier traffic without breaking down so quickly, and there's just less settling happening in the long run compared to older construction techniques that don't include these reinforcing grids.

Mine Shaft Stabilization Using Geogrid Mesh

Polyester geogrid mesh makes a real difference when stabilizing mine shafts, boosting both the strength and safety of underground areas. Basically, how these grids work is by spreading out weight and reinforcing weak spots, which keeps everything stable even when pressures build up. Take the situation in Germany where miners started using these geogrid systems back in 2018. They saw their accident rates drop dramatically while getting more productive work done down below. The mesh holds the shafts properly aligned so they don't collapse inward, something that has saved lives according to the local mining authorities who reported fewer incidents after installation. Safety stats tell the story best really, showing clear benefits once these meshes become part of standard practice.

Retaining Structures for Infrastructure Development

Polyester geogrids find widespread application in building different types of retaining structures, helping keep soil in place and manage loads effectively. When installed properly, these grids spread out the weight across larger areas and stop soil from washing away, which makes them really important for city development work and big infrastructure projects. We see this technology at work all over town actually. Take those highway embankments along Route 9 for instance they wouldn't hold together without geogrid reinforcement. Many engineers who've worked on similar projects will tell anyone that geogrids just work better than traditional methods. The official design manuals recommend using them because they cut down on how much concrete and steel is needed while still giving strong support to whatever structure needs stabilizing. This means cost savings for contractors and safer long term results for everyone involved.

Structural Comparison: Grid vs. Fabric Design

While geogrids and geotextiles both play important roles in civil engineering projects, they serve very different purposes because of how they're built. Geogrids have this grid pattern structure that spreads out weight across surfaces, making them great for adding stability especially when there's tension involved. Think roads or hillsides where things need to hold together despite pressure from above. On the other hand, geotextiles look more like woven fabrics and work well for keeping materials separated, letting water pass through while holding back dirt particles. They're essential for drainage systems and preventing erosion in areas prone to washouts. Research published in the Journal of Materials in Civil Engineering shows that geogrids perform best where strong resistance against pulling forces is needed, like reinforcing road bases or stabilizing steep slopes. Meanwhile, engineers tend to pick geotextiles when good filtration matters most, allowing water to move freely but stopping sediment from escaping. Understanding these differences helps professionals select the right product for each job depending on what kind of stressors the site will face over time.

Reinforcement vs. Filtration: Use Case Scenarios

Geogrids and geotextiles serve different main functions in construction work. Geogrids basically strengthen soil structures by holding embankments and pavement layers together better, which stops soil from shifting around and makes everything stronger under weight. We often see them used on train tracks to keep the rails from getting deformed over time. On the other hand, geotextiles act as filters that let water pass through while keeping dirt and small particles out. Farmers and road builders rely on these materials extensively because they help maintain proper drainage without clogging up over years of use. When building embankments in areas with lots of moisture, geotextiles stop tiny soil particles from mixing into the drainage system below. Most experienced engineers will tell anyone working on bigger projects that combining both types of material usually gives the best results. The right mix ensures structures stay stable while still allowing proper water flow through the system.

Table of Contents

-

Understanding Polyester Geogrid Composition

- Material Structure and Manufacturing Process

- Key Properties: Tensile Strength and Durability

- Enhancing Load Distribution in Soil Layers

- Slope Stabilization with Geogrid Walls

- Preventing Soil Erosion and Differential Settlement

- Cost-Effectiveness Compared to Concrete Solutions

- Long-Term Performance in Harsh Environments

- Sustainability and Reduced Carbon Footprint

- Road and Railway Embankment Construction

- Mine Shaft Stabilization Using Geogrid Mesh

- Retaining Structures for Infrastructure Development

- Structural Comparison: Grid vs. Fabric Design

- Reinforcement vs. Filtration: Use Case Scenarios