Understanding Biaxial Geogrids in Modern Construction

Composition and Structural Design

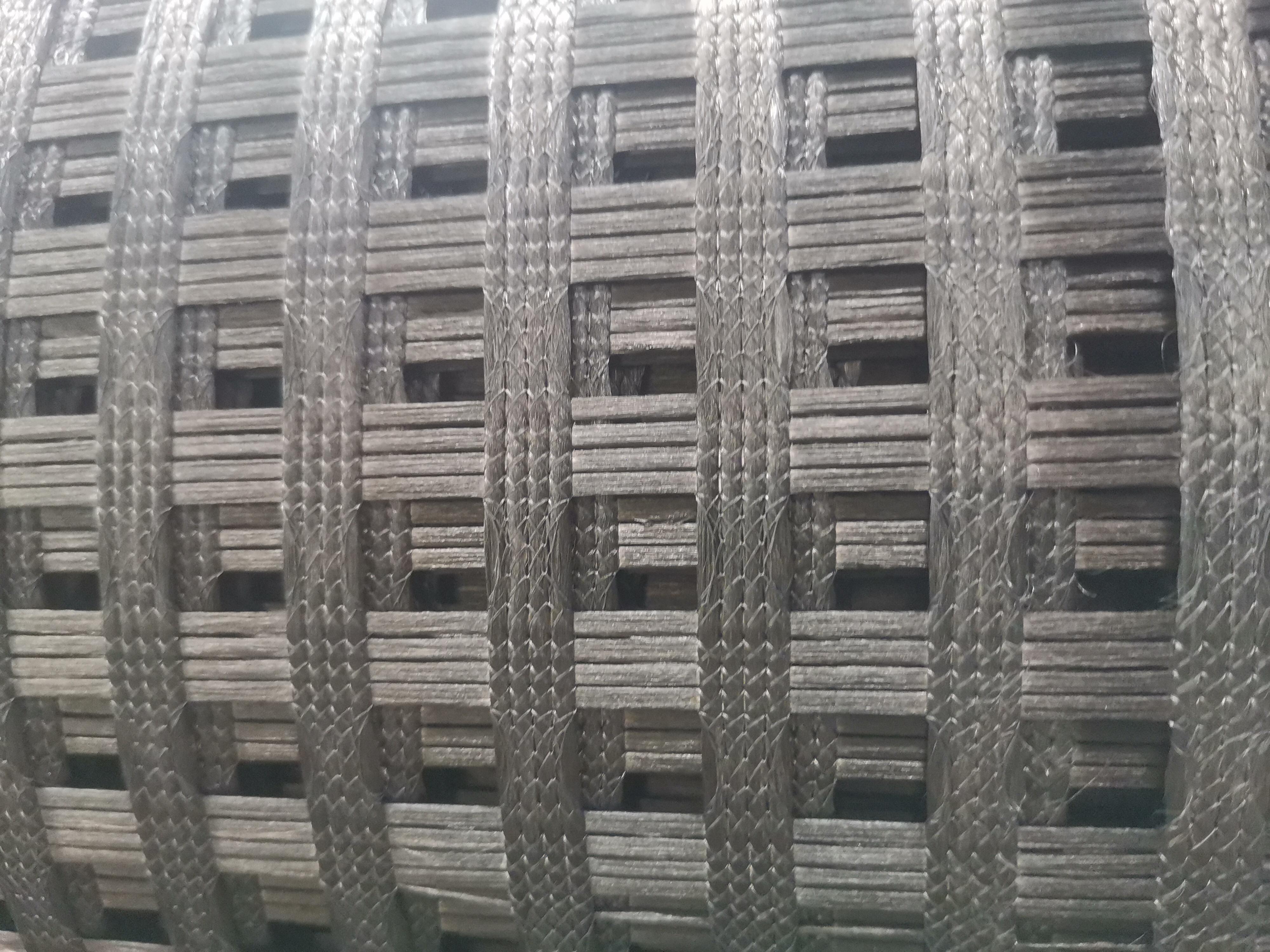

Biaxial Geogrid Material Properties Quality biaxial geogrids are constructed of high tensile strength plastics such as high density polyethylene (HDPE) and polypropylene which are known for their ability to withstand various environmental stressors. These are the materials used in the production of geogrids, because they are designed to withstand the elements over long periods of time, and therefore are perfect to extend the life of any project you choose to undertake. Comparing with uniaxial geogrids, biaxial has better stabilization and reinforcement because it ’ s structure has two elongated apertures with high aspect ratios. The monocoque construction also provides equal tensile and compressive strength in the longitudinal and transverse directions, optimizing load path control over large areas. Multiple researches emphasize the enhanced stability and strength of structures with biaxial geogrids being used as reinforcing elements aiming at more durable and sustainable construction solutions.

Key Properties: Tensile Strength and Aperture Efficiency

Tensile strength is an important characteristic of geogrids, demonstrating their ability to support a load without elongation. It is a critical feature for structural stability when under great pressure, so that it is not deformed under roadways, foundations, and other forms of construction. Aperture efficiency, however, relates to the extent grid openings can retain and transfer soil loads. The size of those openings is critical for the performance, and optimum sizes of those holes will improve the interaction with the soil and prevent subsidence. Industry studies commonly describe co-efficiency of tensile strength and aperture for different geogrid products, biaxial geogrids scoring high in the rankings, so they are the best choice when looking at soil confinement and load support issues.

Key Applications of Biaxial Geogrids in Large-Scale Projects

Roadway and Railway Base Stabilization

Roadways and railways Biaxial geogrids are a vital part of stabilizing bases for roads and rail, as well as reinforcing the weak foundation soils. Patented" For over 30 years, our patended geogrid systems have made roads, parking lots, and drives stronger, safer, and longer lasting with no need to add more materials. One such example would be the application of the biaxial geogrids in the embankment construction of a railway line (Second Avenue Subway in New York City), where the biaxials have been found to blend the base with satisfactory overall stability. Projects using biaxial geogrids have reportedly had a reduction in maintenance costs as high as 30% and pavement life has reportedly been lengthened by 50% versus conventional applications.

Retaining Wall Reinforcement

When we talk about construction of the retaining wall, we may consider reinforcement material such as biaxial geogrid across the board. They decrease lateral earth pressures and improve wall stability. For example, a project on a retaining wall in San Francisco showed that the use of geogrids saved 25% on material cost and enhanced the life time of the wall. This added strength not only promotes better structural stability, it is also expected to result in reduced maintenance costs over the long-term. Requiring reduced, high-mass perimeter walls, these grid systems save you money and help save the environment.

Geo Grid for Gravel Driveways and Parking Lots

Geogrids are essential when it comes to the longevity of gravel driveways and parking areas. They help avert typical driveway problems like raveling and embossment keeping your drive intact and looking great. For these applications, the expert advice is to get the installation right, specifically having a properly prepared subgrade and using appropriate geogrid overlaps for maximum coverage. And there are studies that show this technique can lead to up to 20% savings on materials in the long run, which means that geogrid systems can be a budget-friendly option for surface maintenance.

Airport Runways and Marine Infrastructure

Incorporation with Bias Biaxial geogrid rather than conventional materials results in to notable advantages in airport runway construction. These geogrids provide efficient load distribution which is necessary to promote safety and efficiency in airfield applications. Likewise, in marine structures such as breakwater construction, geogrids offer stability in difficult aquatic conditions:. Projects from the world’s leading airports and marine structures all testify better performance indicators such as enhanced durability and less structural breakage in long term with the help of biaxial geogrids.

Advantages of Biaxial Geogrids Over Traditional Methods

Enhanced Load Distribution and Soil Confinement

Biaxial geogrids performed better in terms of load distribution and soil confinement than traditional materials and reduce soil deformation substantially. These geogrids reduce the stress on the soil below, and subsequently reduce the possibility of displacement and deformation. One such example is the Panipat Refinery Project, where application of Ocean Non Wovens' biaxial geogrid resulted in superior stabilization and lesser soil migration. Case studies have continuously shown that the inherent interlocking nature of biaxial geogrids provides for impressive shear resistance and load-carrying capabilities, proving to be beneficial for a wide range of applications.

Cost-Effective Subgrade Stabilization

Biaxial Geogrids provide great value - economically stabilizing base materials so users save money on the placement of expensive aggregate. They reduce material as well as labor costs, and are a cost-effective option for project managers. Indeed, a recent comparison has indicated that the use of biaxial geogrids can offer a better value over time in savings in maintenance costs. Specialists highlight that this technology does not lower the initial investment only, but also guarantees lower lifetime expenditures. What this means is that biaxial geogrids are a cost-effective investment for cost-conscious jobs that require dependable soil stabilization.

Reduced Material Requirements and Long-Term Durability

Construction work with biaxial geogrid reduces the amount of material needed, thus minimizing construction waste and sustainable building. Their durability means that they require less aggregate, resulting in lower overall project costs and environmental impact. The long term performance of geogrids is widely acknowledged in a host of studies, which demonstrate that they stand up to all conditions year in year out. Enthusiasts of green construction applaud the decrease in material use, solidifying the geogrid’s place in environmentally friendly infrastructure construction.

Incorporating these advanced geosynthetics ensures longevity and stability in modern construction, marking a shift towards more efficient and sustainable engineering practices.

Best Practices for Installing Biaxial Geogrids

Proper Laying Techniques for Maximum Efficiency

In order to achieve the desired performance of biaxial geogrids, laying systems have to be strictly adhered to. First ensure you have the base prepared well, (the surface which the geogrid and pavers are going to be laid on) and this should be levelled. Then, properly position the geogrid per the designed orientation. Here are best practices for attaching biaxial geogrids following the biaxial geogrid installation process: Step 1.

- Base Preparation: Level the ground and remove debris to ensure a smooth surface.

- Alignment: Lay the geogrid flat, making sure it has no creases.

- Overlap: Ensure that adjacent geogrid panels overlap as per design instructions.

- Secure Geogrid: Anchor the edges firmly to prevent displacement during construction.

- Cover and Compact: Cover the geogrid with fill material and compact it to improve interlock.

These practices adhere to industry standards for geogrid installation, ensuring structural stability and soil reinforcement.

Avoiding Common Mistakes in Geo Grid Applications

Common errors during the installation of geo grids, such as inadequate alignment or insufficient overlapping, can severely affect project outcomes. Such mistakes can lead to reduced soil reinforcement and compromised structural integrity, shortening the infrastructure's lifespan. To avoid these pitfalls, it's crucial to:

- Ensure Proper Alignment: Misalignment can hinder load distribution.

- Follow Overlapping Guidelines: Insufficient overlap between panels may lead to gaps in reinforcement.

- Conduct Quality Checks: Regularly inspect installation to ensure compliance with design specifications.

Experts recommend thorough planning and adherence to geo grid application guidelines to guarantee quality, performance, and longevity of the project.