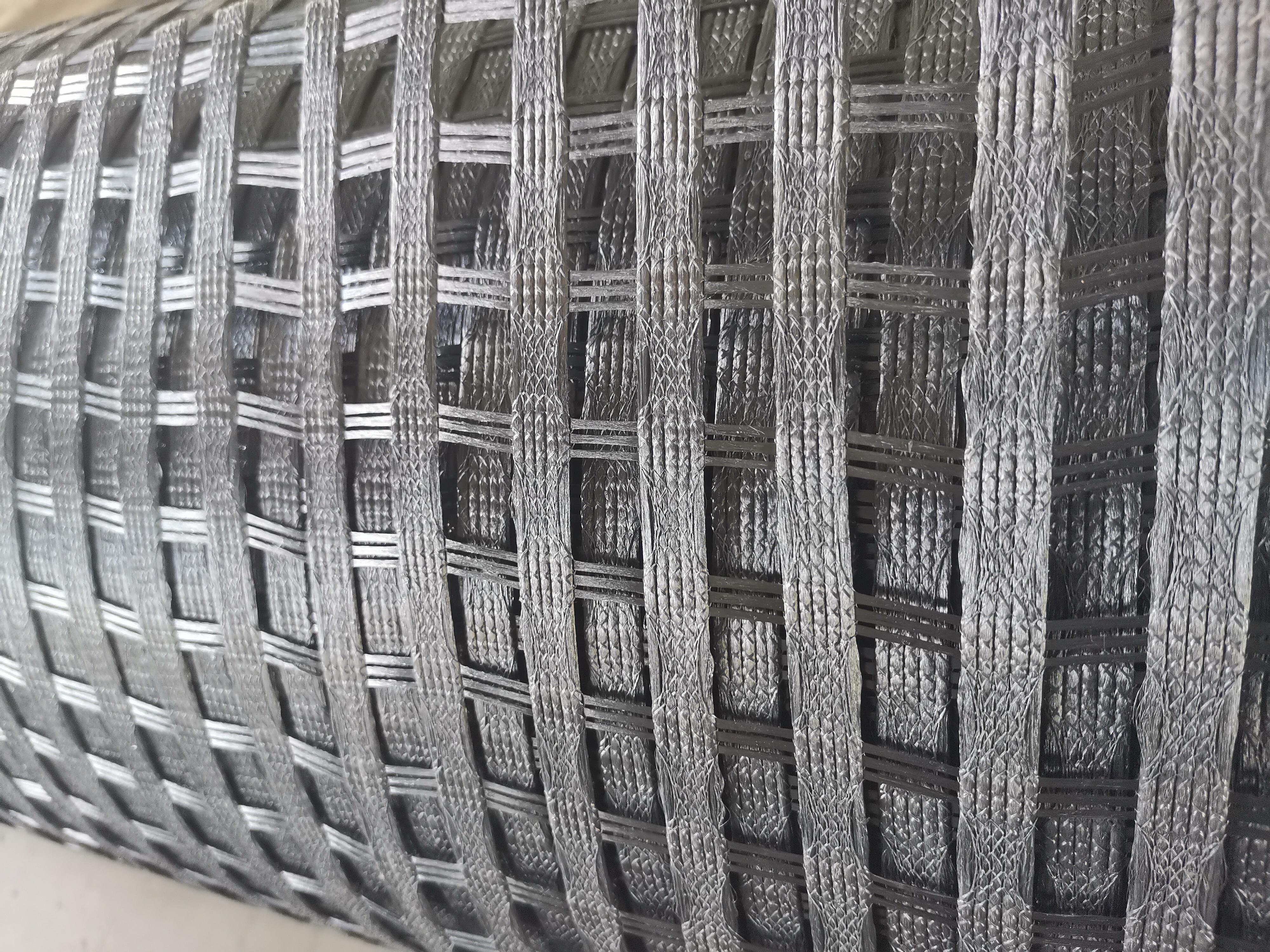

The execution and planning of geogrid uniaxial installation on slopes is relatively complex as it requires precision. The first step involves clearing vegetation, debris, and loose soils from the surface of the slope. Following this, the uniaxial geogrid is unrolled along the slope contour while ensuring that the high-strength axis aligns with the direction of the maximum anticipated load. Soil nails, stakes, and other appropriate anchoring options are employed to hold the geogrid at the top, bottom, and sides of the slope for containment to prevent sliding under load during installation. Interacting with the soil reinforces the slope eliminating sliding failure, so compaction over the geogrid must be done in layers. Ensure that overlapping geogrid sheets follows design specification.

Copyright © 2025 by Shandong Sunshine New Material Technology Co.,Ltd - Privacy Policy