What Is a Uniaxial Geogrid and How Does It Reinforce Soil?

Definition and Structure of Uniaxial Geogrids

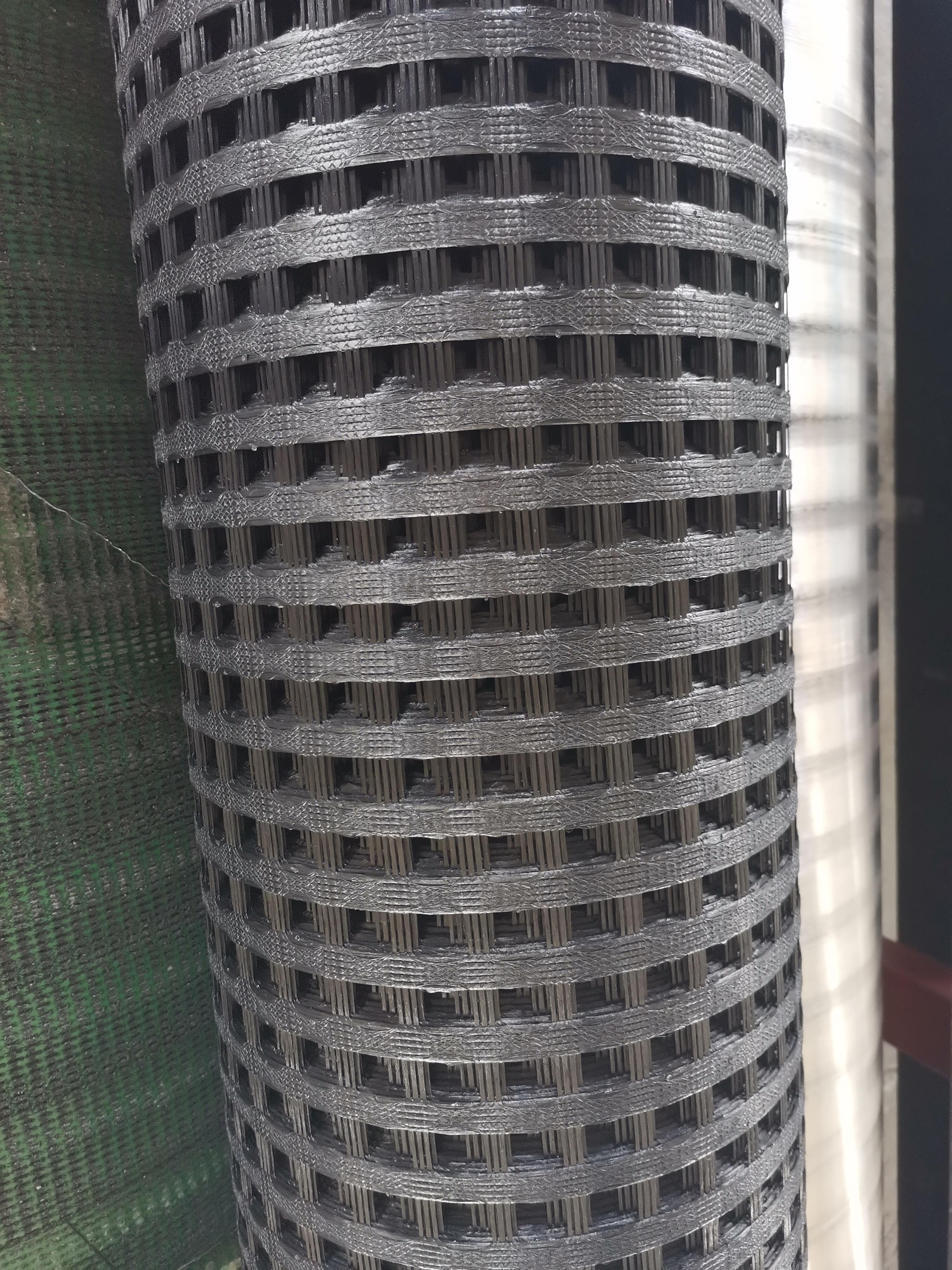

Uniaxial geogrids belong to the family of geosynthetic materials, typically constructed from strong polymers like HDPE or polyester. These grids have those long rectangular holes running in just one direction, creating this ribbed look that gives maximum strength along that main axis. The way they're designed works really well when dealing with forces that come from only one direction, which is why engineers often specify them for things like retaining walls or slope stabilization projects where the pressure comes mostly sideways rather than from all angles.

Mechanical Interlock and Soil-Geogrid Interaction

The open grid structure allows soil particles to pass through and interlock mechanically with the ribs, creating a composite mass. In granular soils, this interaction enhances shear strength by up to 60%, according to 2023 geotechnical studies. By restricting lateral displacement, the geogrid stabilizes the soil matrix and improves load-bearing capacity.

The Role of High Tensile Strength in One Direction

Uniaxial geogrids have tensile strengths that range anywhere between 20 kN/m all the way up to 400 kN/m according to ASTM D6637 standards. These grids work really well at taking in stress and spreading it out along their main direction. For things like retaining walls where most of the pressure comes horizontally from the soil behind them, this kind of reinforcement makes a lot of sense. When we look at how much material gets used compared to traditional methods, there's actually quite a difference. Studies show that projects can cut down on materials needed by somewhere around 15 to 30 percent without sacrificing strength or safety. Contractors find this particularly valuable when working on budget sensitive jobs where every dollar counts but quality remains important.

Key Applications: Retaining Walls, Slopes, and Embankments

Reinforcement of Segmental Retaining Walls

Uniaxial geogrids offer important side support for segmental retaining walls when dealing with soil pushing against them from the sides. These grids can cut down on sideways pressure from the earth by roughly 40 percent compared to walls without any reinforcement according to research from Geosynthetics Society back in 2023. What makes them work so well? Their open spaces let the compacted material behind the wall lock in place mechanically. Plus, these gaps help water drain away properly instead of building up behind the wall. Water buildup behind retaining structures is actually one of the main reasons why walls end up failing over time.

Stabilizing Steep Slopes in Erosion-Prone Areas

When dealing with slopes steeper than 45 degrees, uniaxial geogrids really make a difference in terms of overall stability thanks to their ability to gradually contain the surrounding soil. Tests conducted in dry areas have demonstrated pretty impressive results too - around 70 percent less surface erosion after just five years when compared to untreated slopes. This happens because the geogrids hold onto the top layer of soil better and give plants something solid to grip onto as they grow. Looking at the actual design, those long rib structures work against shearing forces, spreading out the weight of everything above them. This helps prevent that dreaded rotational collapse issue commonly seen on clay filled hillsides where water tends to accumulate and weaken the ground structure over time.

Case Study: Highway Embankments Over Weak Soils

A 2022 highway embankment built on peat soil demonstrated significant performance gains with uniaxial geogrid reinforcement. Post-construction settlement dropped from an estimated 150 mm to 22 mm within the first year. The geogrid’s load-spreading effect reduced fill requirements by 25%, resulting in $180,000 in savings while meeting FHWA’s long-term deformation standards.

Long-Term Performance and Erosion Resistance

Accelerated aging tests simulating 50 years of environmental exposure show uniaxial geogrids retain at least 85% of their initial tensile strength in pH 4–9 conditions. UV-stabilized polymers resist embrittlement, ensuring reliable performance through freeze-thaw cycles. Unlike steel reinforcements, they do not corrode, offering superior durability in aggressive environments.

Performance in Soft Soils: Load Distribution and Settlement Control

Challenges of Building on Soft and Compressible Soils

Soft soils—particularly those with over 40% water content—exhibit low shear strength, often as low as 30.3 kPa, increasing the risk of failure under load. Organic-rich layers can have compression indices (CᾸ') up to 10, leading to prolonged and uneven settlement that compromises structural integrity.

How Uniaxial Geogrids Enhance Load Distribution

When placed at stress-critical interfaces, such as sand-clay boundaries, uniaxial geogrids significantly improve load distribution. Studies show they increase bearing capacity by 560% in very soft clays (Biswas et al. 2024). The longitudinal ribs bridge weak zones, reducing localized stresses by 38–42% compared to unreinforced sections.

Reducing Differential Settlement: Measurable Benefits

Data from 27 infrastructure projects indicate that uniaxial geogrids reduce differential settlement by 67% in peat-supported embankments. One bridgehead project achieved less than 3 mm variation in post-construction settlement using a three-layer geogrid system. For road widening, this approach cuts long-term maintenance costs by $18/m² over a decade compared to pile-based solutions.

Field Data and Performance Metrics from Real Projects

Performance tracking across 14 highway embankments shows:

| Metric | Unreinforced | Geogrid-Reinforced | Improvement |

|---|---|---|---|

| Peak settlement (mm) | 182 | 55 | 69.8% |

| Load capacity (kPa) | 48 | 84 | 75% |

| Construction time (days) | 45 | 32 | 28.9% |

Best results were achieved when aperture sizes matched the 85th percentile of soil particle diameter and geogrids were installed at 0.5 the embankment height.

Design Considerations: Optimizing Aperture Size, Stiffness, and Installation

Laboratory Insights: Pullout Resistance and Interface Friction

ASTM D6706 testing shows pullout resistance is maximized when geogrid aperture size and rib geometry align with soil particle characteristics. Angular crushed stone increases interlock efficiency by 22–35% compared to rounded gravel, enhancing overall system stability (2023 Geosynthetics Conference Proceedings).

Matching Aperture Size and Grid Stiffness to Soil Type

For clay soils, apertures between 25–40 mm balance confinement and drainage. In granular soils, stiffer ribs (≥4 kN/m) resist deformation under lateral loads. However, overly rigid geogrids in soft soils may concentrate stress and reduce effectiveness by up to 30%, emphasizing the need for proper stiffness matching.

Common Pitfalls: Avoiding Over-Engineering in Geogrid Selection

A 2022 DOT report found that 78% of road embankment projects performed equally well with 80 kN/m versus 100 kN/m geogrids, despite the higher cost of the latter. Over-specifying tensile strength leads to unnecessary expenses, with typical overspending between 18–25%.

Best Practices for Efficient Installation and Labor Savings

Critical installation steps include:

- Using laser-guided equipment for ±1 cm alignment accuracy

- Overlapping rolls by 15–30 cm and securing with polymeric connectors

- Preventing soil contamination during placement to preserve friction properties

Trained crews complete installations 40% faster than untrained teams, according to FHWA construction guidelines (2021), significantly improving project timelines.

Advantages of Uniaxial Geogrids: Durability, Cost, and Project Efficiency

Cost-Effectiveness vs. Traditional Reinforcement Methods

Uniaxial geogrids cut project costs by up to 40% compared to concrete walls or aggregate-intensive foundations. By improving load distribution, they reduce material needs by 25–50% in road and slope applications (ASCE 2023). Their modular, prefabricated form also minimizes waste, lowering labor and disposal costs.

Long-Term Durability and Resistance to Environmental Stress

Made from materials like HDPE or PET, these uniaxial geogrids stand up pretty well against UV damage, chemicals, and really harsh temperatures ranging from -40°C all the way up to +80°C. Tests on actual installations have found that even after half a century buried in tough soil conditions, there's typically less than 1% reduction in strength compared to when they were first installed. That kind of durability puts regular steel to shame since it corrodes so easily over time. Plus, their grid pattern allows water to drain through instead of pooling up, which helps prevent those dangerous pressure buildups we see on steep slopes and around retaining walls.

Streamlined Deployment and Reduced Construction Time

Installation is 30–50% faster than traditional methods. Lightweight (2–4 kg/m²) and supplied in large rolls, geogrids require no heavy lifting equipment. A 2023 highway project achieved 98% compaction in just six days—45% faster than stone column alternatives—demonstrating clear gains in speed and efficiency.

FAQ

What are uniaxial geogrids made from?

Uniaxial geogrids are typically constructed from strong polymers like HDPE or polyester.

Why are uniaxial geogrids effective for retaining walls?

Uniaxial geogrids provide significant lateral support to retaining walls, reducing pressure from the earth by allowing compacted materials to interact and stabilizing the wall structure.

How do uniaxial geogrids improve soil reinforcement?

Through mechanical interlock, soil particles pass through the grid structure and create a composite mass, enhancing shear strength and restricting lateral displacement, thereby improving load-bearing capacity.

Can uniaxial geogrids be used in soft soil conditions?

Yes, they enhance load distribution and reduce differential settlement in soft soils. They are particularly effective at stress-critical interfaces to improve bearing capacity and bridge weak zones.

Table of Contents

- What Is a Uniaxial Geogrid and How Does It Reinforce Soil?

- Key Applications: Retaining Walls, Slopes, and Embankments

- Performance in Soft Soils: Load Distribution and Settlement Control

- Design Considerations: Optimizing Aperture Size, Stiffness, and Installation

- Advantages of Uniaxial Geogrids: Durability, Cost, and Project Efficiency

- FAQ