מבנה ועקרונות מכניים של ג'יאוגריד חד-צירי

הגדרה ועיצוב המבנה של ג'יאוגריד חד-צירים

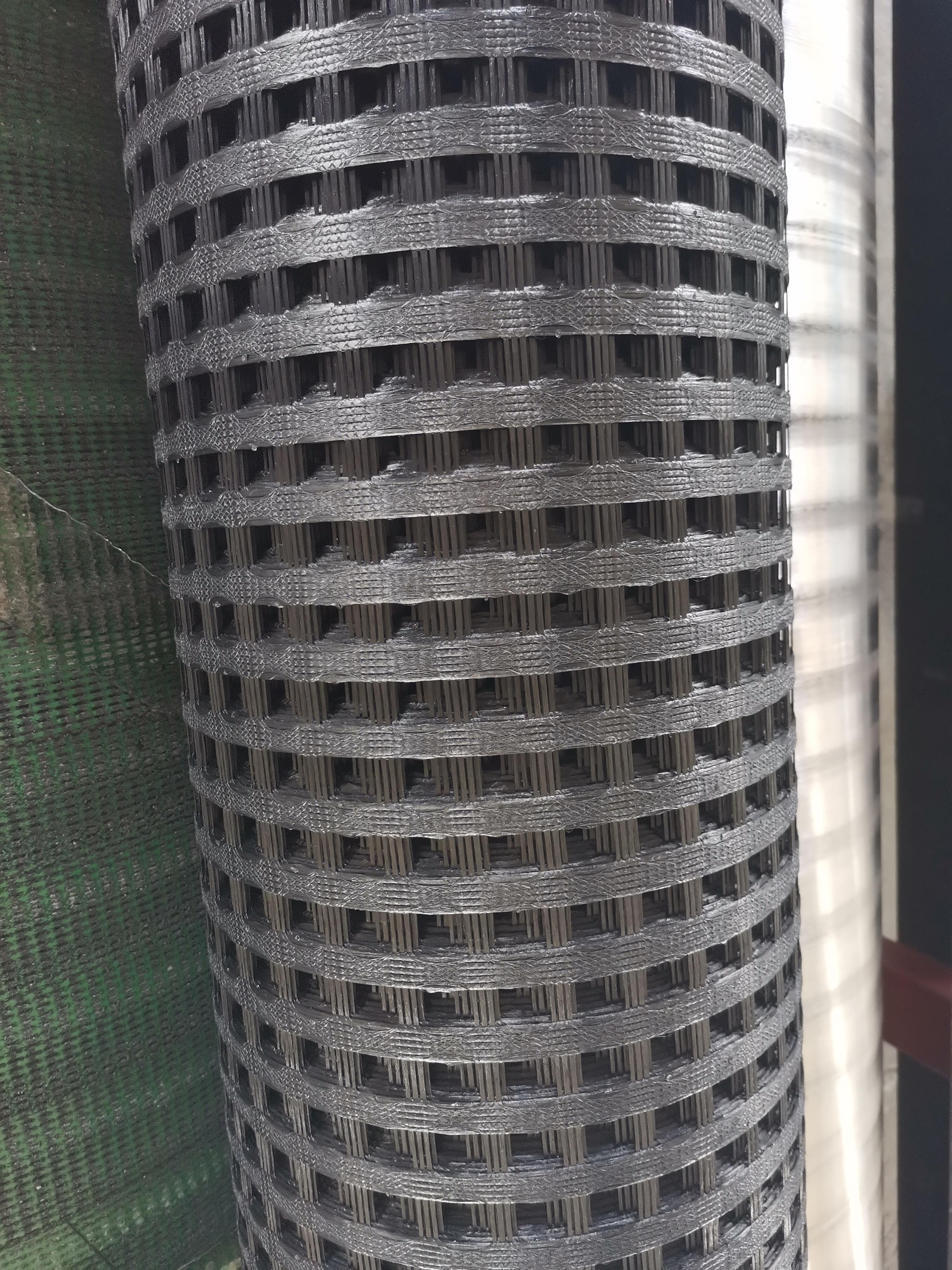

ג'יאוגרידים חד-צירים מורכבים בעיקר מהרצפות פלסטיק, לרוב מיוצרות מ חומרים של HDPE או PET, שפותחו במכוון כדי לחזק מבנים רק בכיוון אחד. הרצפות אלו מכילות פתחים מלבניים ארוכים וצלעות ישרות הנעות במקביל אחת לשנייה, מה שנותן להן את הכוח בעיקר לאורך הרצפה. העיצוב הזה מאפשר העברת כוחות באופן יעיל על פני משטחים מבלי להזדקקו לכמויות גדולות של חומר. כאשר יצרנים מ Extrude ומרחיבים פולימרים אלו במהלך הייצור, הם למעשה מסדרים את המבנה המולקולרי בתוך החומר עצמו. כתוצאה מכך, המוצרים הללו יכולים להגיע לערכים מרשימים של חוזק מתיחה, בערך 400 קילו ניוטון למטר לפי סטנדרט ה-ASTM. זה הופך אותם למוצרים אידיאליים לפרויקטים בהם יש לשמור על יציבות בעיקר בכיוון אחד ולא בכמה כיוונים בו-זמנית.

חוזק מתיחה ומנת ההעברה החד-כיוונית של עומס

עיצוב חד-צירי מכוון את רוב עוצמתו לאורך הציר הראשי, מה שעוזר לו לעמוד מול מאמצי מתיחה בעייתיים הנמצאים בקירות תומכים ובמבני talus. כאשר משקל מופעל, המאמץ עובר דרך הצלעות ומתפשט על פני שטח גדול יותר. זה בעצם מקטין את כמות העיוות שנוצר בקרקע בנקודות מסוימות. לפי מגוון מבחנים שנערכו על חיזוק תת-רציף, המערכת הזו יכולה להגביר את קשיחות הקרקע ב-35 אחוז בערך בהשוואה לקרקע רגילה ללא כל חיזוק. די מרשימה עבור משהו שעומד שם בסךו של דבר ומחזיקה הכל יחד.

תפקיד מפתח של גאומטריית הפתח באפקטיביות החיזוק

צורת הפתחים מושכת תפקיד חשוב באופן שבו הקרקע מתאימה לסיכת גיאוגריד. כשмы מביטים בפתחים מרובעים שיש להם יחס צלעות של בערך 3 ל-1 או אפילו 5 ל-1, הם נוטים ליצור חיבורים מכאניקיים טובים יותר בין החלקיקים. זה יוצר סוג של חיבור מכאניקלי שמונע מהאדמה לנוע הצידה יותר מדי. מחקרים מצביעים על כך שכשנכונים את גודל הפתחים בצורה נכונה, הם יכולים להגביר את החיכוך במשטח interface בין 20% ל-30%. זה גורם למערכת כולה להיות יציבה יותר בפועל. יתרון נוסף של הצורות הארכות הללו הוא שהן מתנגדות לסגירה כאשר הלחץ גדל, מה שממשיך לשמור על תעלות הזרימה פתוחות ומשמר את ההתנגדות לכוחות הגזירה במהלך יישור העומס.

אינטראקציה בין קרקע לסיכת גיאוגריד: המדע של החיבורים המכאניקליים

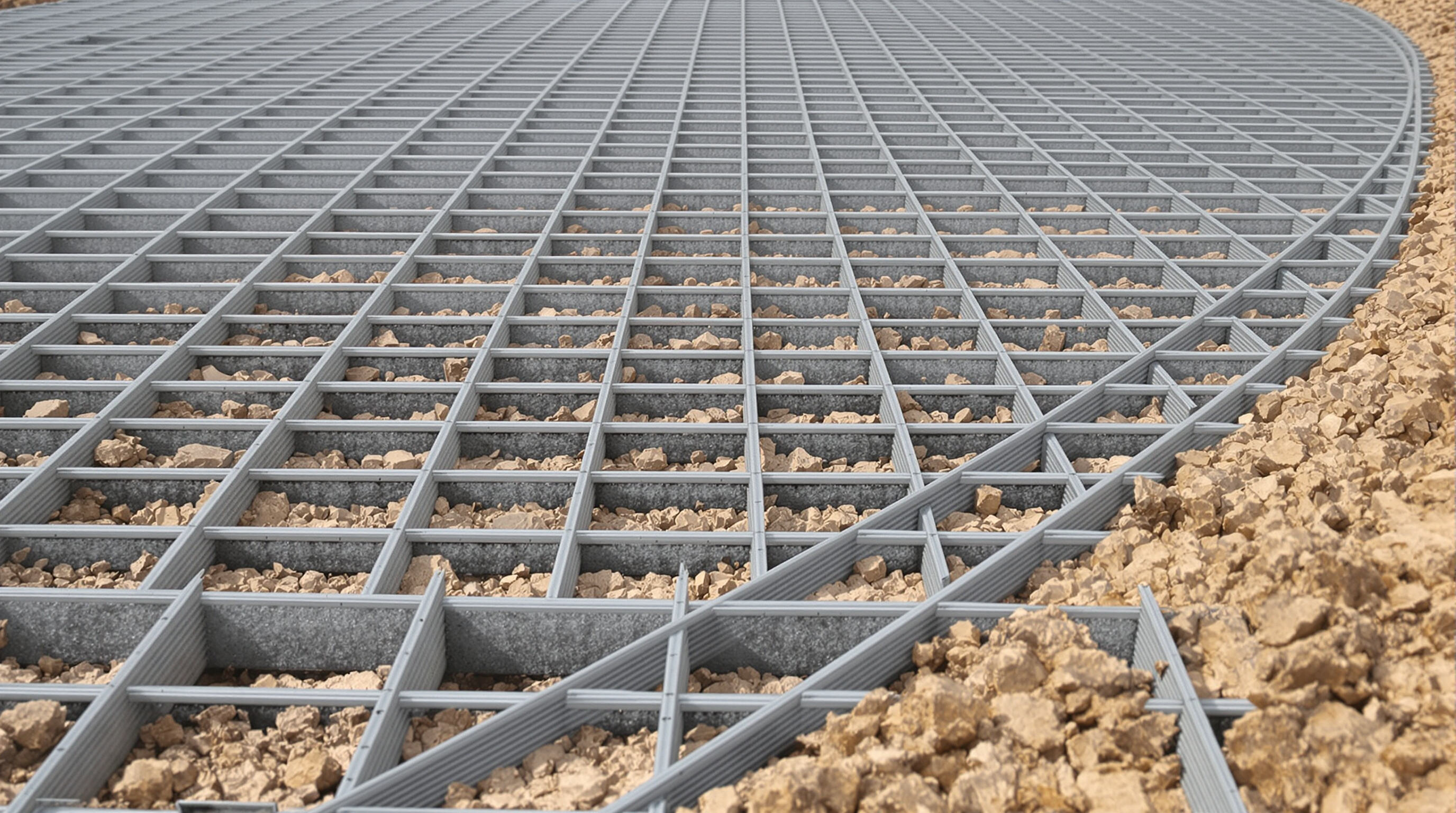

חיבורים מכאניקליים מול חיכוך: הבנת מנגנוני התפלגות העומס

בנוגע ליציבות קרקע, סריגים גיאוטכניקיים חד-צירים פועלים בעיקר בזכות נעילה מכאנית ולא רק בגלל החיכוך הפנים-חומרתי על פני השטח. מחקר של Geosynthetics International משנת 2022 הראה כי תכונות הנעילה הללו תורמות ליציבות של 40 ועד אולי 60 אחוזים יותר התנגדות לתנועת הקרקע בהשוואה למה שחיכוך בלבד יכול להציע. בעיקרון, הצלעות של הסריג תופסות את חלקיקי הקרקע בתוך הפתחים הקטנים, ו יוצרות מעין מבנה קומפוזיטי תלת-ממדי. המבנה הזה עוזר לפזר כוחות אנכיים בצורה אופקית לאורך האזור שבו יש צורך בחיזוק, וכך הופך את כל המערכת יציבה בהרבה.

איך חלקיקי הקרקע מתאימים לפתחים בסריג הגיאוטקסטיל כדי להשיג יציבות

התפסות עובדת בצורה הטובה ביותר כאשר גרגרי הקרקע מצליחים להשתכן באופן חלקי בתוך הפתחים של הרשת הגיאו-סינטטית. כדי שהדבר יתבצע כראוי, פתחי הרשת צריכים להיות גדולים פי 1.2 עד 2.5 מהגרגרים הגדולים בקרקע. סלע משונה עם קצוות זוויתיים מספקת כ-28 אחוזים יותר התנגדות נגד נסיגה בהשוואה לאגרגט חלק. הדבר נובע מהעובדה שהפינות החדות חודרות טוב יותר לתוך חומר הרשת. בעת ההתקנה של הרשתות, חשוב מאוד לוודא שהחלק החזק ביותר של הרשת יעבור בדיוק בנקודות בהן ייתכן כשל. התאמת ההטיה הזו היא מה שמקנה את ההבדל בביצועים לאורך זמן.

גורמים המשפיעים על יעילות חיזוק: סוג הקרקע ודחיסה

אדמות המכילות מעל 35% חול נוטות ליצור חיבורים טובים יותר בין חלקיקים, בעוד אדמת חימר קשוחה דורשת כ-95% איטום פשוט כדי לשמור על תאי האוויר הבלתי רצויים תחת שליטה. כשמדובר באדמות בדרגה טובה, כל עלייה של 10% בצפיפות היחסית אכן מגבירה את חוזק החיבורים ב-15% בערך, על פי סטנדרטים של ASTM משנת 2021. חשוב לא פחות הוא להשיג את אחוז הרטיבות הנכון בזמן האיטום. הטווח האידיאלי הוא בדרך כלל פלוס או מינוס 2% מהכמות האופטימלית. אם האדמה יבשה מדי, החלקיקים לא ינועו כראוי, אך אם עוברים את הנקודה המתוקה הזו, הדברים הופכים חלקלקים במקום שאיטום מתבצע כראוי.

שיפוע יציבות האדמה באמצעות גאوجריד חד-צירי

שיפור קשיחות האדמה ואיטומה במדרכות תומכות חלשות

גיאוגרידים אוניאקסיים מביאים תועלת רבה בקרקעות רכות מכיוון שהם יוצרים שכבה קומפוזיטית חזקה כאשר הם ננעולים יחד עם חלקיקי האגרגט. המאפיין העיקרי של גידים אלו הוא חוזק המשיכה המרשיע שלהם, אשר מונע מהחלקים הקטנים של הקרקע לנוע יותר מדי. מחקרים הראו שזה יכול להגביר את הקשיחות של תת-הבסיס בכ-40 אחוז בקרקעות קוהזיביות בהשוואה לאזורים ללא חיזוק. מה זה אומר בפועל? זה אומר שמהנדסים יכולים לעבוד עם קרקעות שאינן באיכות טובה, אך עדיין לגרום להן לעמוד בעומס. זה חוסך כסף מכיוון שיש פחות צורך לחפור את הקרקע הרעה ולחלופה במטלה טובה יותר.

מניעת עיוות laterלי בקרקעות רכות ומשופרות

הקמטים החד-כיווניים יוצרים התנגדות ממוקדת לתנועת אדמה אופקית. ביישומים של חימר רווי, גיאו-сетים עם כיוון נכון מפחיתים את העקיצות הצדדית ב-50–65% על ידי העברת מאמצי גזירה לאורך האורך שלהם. האפקט הזה של הכלה הוא קריטי במדרכות שנחשפות לטעינה מחזורית מתחבורה או לחִרְצָה.

הפחתת שקיעות דיפרנציאליות במערכות יסודות

על ידי העידוד של התפלגות מאמצים אחידה בתנאי אדמה משתנים, גיאו-сетים חד-צירים מפחיתים שקיעות מקומיות שעלולות להוביל לנזקי מבנה. מחקר גאוטכני משנת 2022 הדגים הפחתה של 72% בשקיעות דיפרנציאליות כאשר שכבות מוגזמות עם גיאו-סֶט הותקנו מתחת ליסודות רדודים באדמה הטרוגנית.

אופטימיזציה של התפלגות מטענים אנכיים וצדדיים בעזרת הגזמה ממוּשֶׁרֶת

קווים פולימריים מכוונים מפנים מאמצים לאורך הציר הראשי של הרשת הגיאו-סינתטית, תוך אפשור עיבור צדדי מבוקר. יישור כיווני זה מותאם לכוח הגידור הצפוי, ומביא להגברת יעילות הפצה של העומס ב-20–30% לעומת חומרים איזוטרופיים ביישומים כמו כתפי גשרים ומעבר מדרון.

יישומים בשטח בדפנות תומכות ובמדרונות תלולים

עיצוב ויישום של רשתות גיאו-סינתטיות חד-ציריות במבנים תומכים

ג'יוגרידים שפותחו כדי לחזק בכיוון אחד הפכו למרכיבים סטנדרטיים בבניית קירות MSE מאחר שהם יכולים להתמודד עם מתחים לאורך כיוון אחד בצורה אפקטיבית. במהלך בניית המבנים הללו, מהנדסים ממקמים סריגים מפוליאתילן בצפיפות גבוהה בין שכבות הקרקע המודבקות במרווחים של בדרך כלל חצי מטר ועד כ-1.2 מטר. מחקר שנערך בשנה שעברה הראה כי כאשר הם מותקנים בצורה נכונה, השרשורים הללו מקטינים את הלחץ הצידי על הקירות בכ-38 עד 40 אחוזים בהשוואה לקירות ללא חיזוק. משמעות הדבר היא שהמהנדסים יכולים לבנות קירות תומכים גבוהים יותר תוך שמירה על היציבות, מבלי שיהיה צורך בשטח גדול יותר לבסיסים כפי שדרוש בשיטות המסורתיות.

מקרה לדוגמה: חיזוק קיר תומך בגובה 8 מטר

עבור בניית כביש חופי לאורך חוף האוקיינוס השקט, מהנדסים היו צריכים לייצב שיפוע תלול למדי של 62 מעלות באמצעות חיזוק גיאוגריד חד-צירי. בסופו של דבר הם התקינו 14 שכבות של גיאוגרידים בעוצמה של 30 קילו-ניוטון למטר, כל אחת במרחק של כ-60 סנטימטרים זו מזו. לאחר שצפו מקרוב בפרויקט במשך כמעט 18 חודשים לאחר השלמתו, הם הבחינו בתנועה צידית של 8 מילימטרים בלבד - וזה די יוצא דופן, שכן זה טוב בכ-84 אחוזים ממה שקורה בדרך כלל בשיטות מסורתיות. פתחי הרשת נמדדו בגודל 45 על 80 מילימטרים ועבדו מצוין עם החימר החולי שמתחת, ונעלו חלקיקים יחד ביעילות של כ-92 אחוזים, על פי בדיקות שבוצעו באתר.

שיטות התקנה מומלצות: יישור, חפיפה, ועיגון

התקנה נכונה של רשתות גיאו חד-ציריות כוללת:

- יישור כיווני : סידור צלעות מתיחות בזווית ישרה למישורי כשל פוטנציאליים

- נהלי חפיפה : חפיפה מינימלית של 0.3 מ' בין הגלילים, עם חיזוק באמצעות קונקטורים פולימריים

-

פרטי סיום : טקסית של הרשת הגיאו-סינטטית לפחות 1.2 מ' מעבר לגוש השבירה הפעיל

בדיקות בשטח מראות כי עמידה בנהלים אלו מאריכה את תקופת השירות של המערכת ב-50–60%, במיוחד בסביבות של הקפאה-המסה.

יתרונות יעילות ביצועים ותפעול של הרשת הגיאו-סינטטית החד-צירית

מערכות הרשת הגיאו-סינטטית החד-צירית מציגות יתרונות כלכליים וביצועיים משמעותיים על ידי אופטימיזציה של השימוש בחומרים, האצת ההתקנה ומבטיחות ביצועים לאורך זמן.

הפחתת עלויות הפרויקט על ידי אופטימיזציה של השימוש בחומרים

הרשתות הללו מפחיתות את הלוואי על חומרים יקריים imorted כמו حصי או סלעי טחינה על ידי שיפור היכולת לספוג עומסים של הקרקעות המקומיות. שילוב של רשתות חד-ציריות בחיזוק תת-הבסיס יכול להפחית את הדרישה לאגרגטים ב-30–45% תוך שמירה על שלמות מבנית, וכך להפחית את עלויות הקנייה וההפצה.

האצת לוחות הזמנים של הבנייה על ידי התקנה מהירה יותר

גיאוגריד חד-צירי קל במשקל ופשוט בעבודה, מה שמאפשר פריסה מהירה ללא צורך בכלים מיוחדים. צוות typici working on site typici manages around 1,000 square meters each day עם כלים ידניים רגילים וככל הנראה-loader קטן. זה מקטין את עלות העבודה במשולש בהשוואה לשיטות מסורתיות המשתמשות בخرס גלוי. המהירות הזו הופכת את הרשתות הללו לכלי יעיל במיוחד בעבודות בהן הזמן הוא קריטי, כמו תיקוד כבישים לאחר תאונות או סלילת מדרונות לאחר גשמים כבדים, כשהצורך להחזיר everything to order הוא דחוף.

עמידות לטווח ארוך וצורך מופחת בתקופות תחזוקה

ג'יאוגרדיות חד-צירתיות שנבנו מחומרים HDPE או PET יכולים לעמוד נגד התפרקות כימית, נזק UV, ואפילו רקיעה ביולוגית במשך יותר מ -75 שנים ברוב התנאים. הדרך שבה המערכות האלה מתוכננות בכיוון אחד מונעת מהם להתמתח לאורך זמן כאשר משקל מוחזק כל הזמן, מה שאומר שהם ממשיכים לעבוד כראוי אפילו בתקופות ההטמעה החורבות והרעידות האדמה הבלתי צפויות. אם מסתכלים על תוצאות העולם האמיתי, הייתה התצפית ארוכת טווח שנמשכה 12 שנים שלמות על מתקני קירות תמיכה שונים, שהראה משהו די מרשים - הוצאות תחזוקה ירדו ב-85% בהשוואה למבנים רגילים עם אדמה שלא היו מחוזקים כלל.

שאלות נפוצות

-

ממה מיוצרים רשתות גיאו סטריפס חד-ציריות?

רשתות גיאוגרפיות חד-צירתיות בנויות בעיקר מפלייתילן עם צפיפות גבוהה (HDPE) או פוליאסטר (PET). חומרים אלה מופצים ומתוחים כדי ליישר את מבנה המולקולרי שלהם, ומספקים עוצמת נמשק משמעותית. -

איך מסגרות גיאוטקסטיל חד-ציריות תורמות לעמידות הקרקע?

מסגרות גיאוטקסטיל חד-ציריות משפרות את עמידות הקרקע על ידי חיזוקה בכיוון אחד, פיזור מאמצים על פני שטח, מניעת עיוות laterally, וקידום פיזור מאמצים אחיד, מה שמפחית שיקועים דיפרנציאליים. -

מהו תפקידו של הגאומטריה של הפתחים במסגרות הגיאוטקסטיל?

הגאומטריה של הפתחים, ובפרט פתחים מלבניים עם יחס צלעות מסוים, מעודדת נעילה של חלקיקים ומגביר את החיכוך במשטח הממשק והסילוק של מים, מה שתרום לעמידות המערכת הכוללת. -

איך מתקינים מסגרות גיאוטקסטיל חד-ציריות?

התקנה נכונה של מסגרות גיאוטקסטיל חד-ציריות כוללת יישור כיווני, חפיפה לפי נהלים, וחיזוק מעבר לגוש השבירה הפעיל. פעולות אלו מאריכות את חיי המערכת ומשמרות את שלמותה המבנית. -

מדוע מסגרות גיאוטקסטיל חד-ציריות יתרונות לבנייה?

הגרידים הגיאוגרפיים הללו מפחיתים את עלות הפרויקט על ידי אופטימיזציה של השימוש בחומרים, מצפינים את זמני הבנייה עקב התקנה מהירה יותר, ומציעים עמידות לטווח רחוק, ובכך מקטינים משמעותית את צורכי התפעול.