Fundamentals of Soil Strength in Foundation Engineering

Key Factors Influencing Soil Bearing Capacity

Getting a handle on soil bearing capacity matters a lot when designing foundations because it tells engineers what kind of weight the ground beneath can actually hold. The makeup of the soil makes all the difference too. Clay tends to be stronger than sand or silt, which means foundations built on clay usually have better load support. Moisture levels also play a big part in this equation. When seasons change or if there's water nearby, the soil gets weaker as water moves around inside it, creating pressure shifts that affect stability. That's why regular checks and occasional fixes are needed to keep things steady. Soil depth counts too. Deeper layers need more thorough testing since they carry more weight from everything above them. Good soil compaction methods matter as well whether we're talking about dynamic, static, or vibratory approaches. These techniques pack the soil tighter, making it stronger overall. Before breaking ground, taking time to properly assess the soil conditions ensures that whatever gets built will sit nicely where it belongs, matching construction plans with what the earth can realistically handle.

Challenges of Weak or Unstable Soils

Working with poor quality or unstable ground presents major headaches for foundation engineers who need to conduct detailed geotechnical studies first. Borehole tests become absolutely necessary to get a clear picture of what's going on beneath the surface. Problems range from buildings sinking unevenly into the earth to dangerous soil liquefaction during earthquakes, plus differential settlement that literally cracks structures apart. There are workarounds though. Engineers often turn to soil nailing, chemical grouting injections, or layering geogrid materials between soil layers to spread weight better across foundations. What really matters is keeping an eye on things after construction wraps up. Regular checks and repeated analysis months and years down the road help catch early warning signs before they turn into disasters. Most experienced contractors know this stuff isn't just theory it's about building something that stands the test of time without collapsing unexpectedly somewhere down the line.

Geogrid Technology: Mechanics and Soil Interaction

How Geogrids Enhance Soil Stability Through Interlock

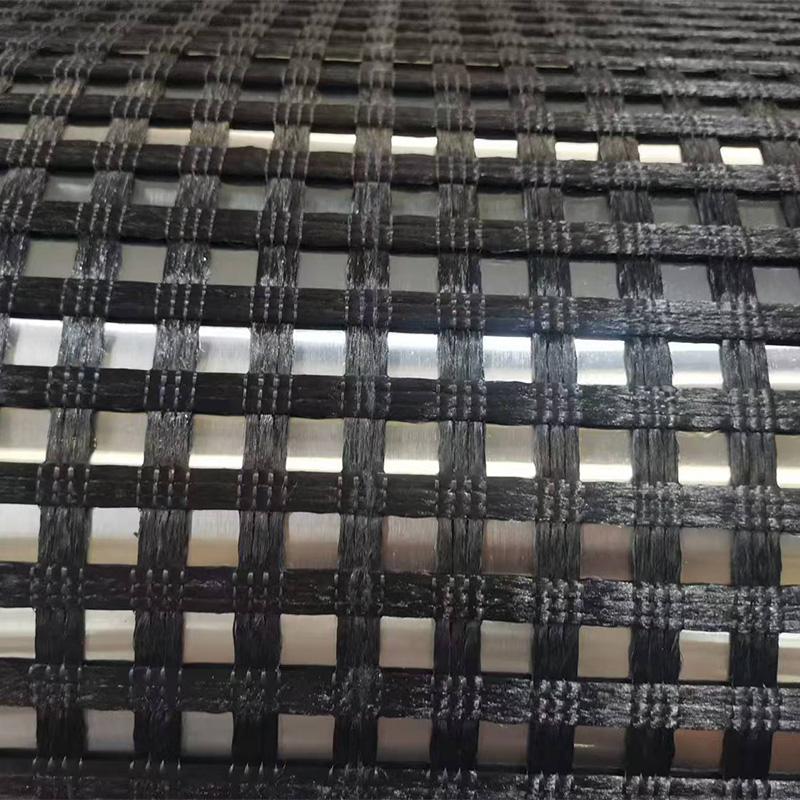

Soil stability gets a major boost when geogrids are used because they form sort of a mechanical grip with the surrounding earth, spreading out loads over bigger areas instead of concentrating them in one spot. The way these grids actually work comes down to their design patterns mostly triangles or squares that bite into the soil particles and hold everything together better. Different grid patterns matter a lot here along with what kind of material makes up the grid itself. Field tests show that adding geogrids can make soil hold about 40% more weight than regular untreated ground, which means real money savings for road builders and foundation contractors. Still there are some environmental issues to watch out for though. Things like repeated freezing and thawing cycles can break down the grids over time, not to mention biological degradation from microbes eating away at certain plastics. That's why picking the right materials matters so much if we want these systems to last through all sorts of weather conditions without failing unexpectedly.

Load Distribution via Geogrid Mesh and Geo Grid Fabric

Geogrid mesh structures are really important for spreading out loads and dealing with those pesky pressure spots in unstable soils. When the weight gets distributed properly across the ground, it stops certain parts of the soil from getting too stressed out, which helps prevent things like shifting or collapse altogether. Different kinds of geogrids work better under various circumstances. Take biaxial ones for instance they handle tension equally well in all directions, so they're great for roads and pavement projects where weight needs to be spread out evenly in multiple directions. Field tests over the years have shown pretty clearly that these grids actually make a difference in how soil behaves under pressure. Most engineers recommend putting geogrids into action where the soil isn't very strong or in places where erosion is a problem. These are exactly the situations where the extra stability provided by geogrid tech makes the biggest impact on project success rates.

Types of Geogrids for Foundation Reinforcement

Uniaxial vs. Biaxial Geogrids: Structural Applications

When it comes to reinforcing foundations, both uniaxial and biaxial geogrids play important roles. The uniaxial type is basically built to handle strength mainly in one direction, so they work really well when dealing with linear loads. Think about things like stabilizing slopes or retaining walls where forces come from just one angle. Biaxial geogrids are different though. These bad boys distribute loads evenly across both lengthwise and crosswise directions. That makes them great for stuff like roadways and pavement systems where consistent strength matters everywhere. Choosing between these two options isn't always straightforward. Engineers need to look at what the actual site looks like and figure out exactly what kind of loads will be present before making a decision.

Looking at real world applications makes it clear why project requirements matter so much when choosing materials. Uniaxial geogrids work great for reinforcing walls against erosion problems and can really extend how long structures last before needing repairs. When it comes to roadways though, biaxial options are often the way to go because they handle stress from multiple directions. The labs keep showing that tensile strength remains a key factor in how well these products perform under pressure. Field tests over the years have repeatedly confirmed what engineers already suspected about their capacity to hold up under heavy traffic without compromising stability.

Triaxial Geogrids for Complex Load-Bearing Scenarios

Triaxial geogrids present an excellent option when dealing with complicated loads that come from different directions in foundation work. These grids handle stress differently compared to regular uniaxial and biaxial types because they spread out forces at various angles, which gives better support for uneven or really heavy weights. That's why engineers often choose them for things like building up slopes or reinforcing road bases where weight distribution isn't straightforward. What sets these apart is their special triangle-shaped openings that hold soil together more effectively. This means the ground can take on heavier loads without collapsing, making triaxial geogrids particularly useful in challenging construction sites where standard solutions just won't cut it.

Real world applications show just how beneficial triaxial geogrids can be when dealing with tough ground conditions. Take road construction projects for instance, where these grids have helped stabilize soils under heavy traffic loads without failing. What makes them stand out is their ability to spread weight across larger areas, which cuts down on project expenses. Traditional approaches often require digging deep trenches and hauling in tons of extra materials, but triaxial systems eliminate much of that work. As researchers continue experimenting with new polymer blends and manufacturing techniques, we're likely to see even better performance from these products in the coming years. Many civil engineers already consider them essential tools for solving tricky foundation problems in both urban and rural settings.

Geogrid Walls and Retaining Structures

Geogrid walls work really well as retaining structures, giving much needed side support in all sorts of landscapes from steep hillsides to flat terrains. The secret lies in those geogrid layers that actually hold back the sideways pressure from the soil behind them, keeping slopes stable and stopping dirt from washing away over time. Designing these walls involves thinking about several key elements though. How tall does the wall need to be? What kind of materials will stand up to local weather conditions? And what about how the wall affects surrounding ecosystems? These considerations make a big difference when deciding if a geogrid wall is right for city streets or countryside farms.

Case studies across multiple regions show how geogrid walls work well for soil stabilization without compromising structural integrity. Take flood zones where these retaining walls have cut down on soil erosion problems significantly. They stand up pretty well against different weather conditions too. The field is changing fast though with new tech coming into play. Smart geosynthetics now let engineers monitor loads as they happen and get advance warnings about potential issues before they become serious problems. This kind of technology makes geogrid walls even safer over time and gives contractors better data to work with when planning long term maintenance schedules.

Practical Applications and Best Practices

Case Study: Geogrid-Stabilized Highway Foundations

Geogrid stabilization has made quite an impression on highway foundation work lately, mainly because it cuts down on construction time and saves money overall. Take for instance what MnDOT did when they started using geogrids for their highway foundations back in Minnesota. The results were pretty impressive actually. These grids helped tackle those tricky problems we always run into with old glacial terrain and poor quality soils. Construction crews found themselves finishing sections faster than expected while staying within budget constraints. Looking at actual project data shows something interesting too settlement rates dropped considerably according to independent evaluations. This means roads built with geogrids settle less over time compared to conventional methods used before.

What we've really picked up on with these geogrid stabilized foundations comes from actually putting them into practice. Through various design tests and watching how they perform in the field, engineers have made changes that pay off big time down the road. Maintenance bills go way down and structures last much longer than traditional methods. Take this particular project for instance it shows just how good geogrids can be when it comes to keeping roads intact. We see fewer potholes forming and repairs happening less frequently year after year. For anyone looking at infrastructure projects, this kind of evidence makes a strong case for incorporating geogrid technology from day one.

Site Preparation and Geogrid Installation Guidelines

Getting the site ready properly makes all the difference when it comes to how well geogrids perform over time. When we prepare sites correctly, we're setting up a solid foundation that stands up better against various loads and stresses. Installation requires some pretty careful work too. Contractors need to follow those soil compaction guidelines closely while making sure grades are right on point so the geogrid sits nicely on top of everything else. A lot of problems down the road come from cutting corners during this stage, which nobody wants especially since these materials can last decades if done right from day one.

Getting good results means steering clear of some basic mistakes like poor alignment issues or not compacting properly. When these things happen, they really mess with how well the geogrid works and can lead to serious structural problems down the road. Following proper installation standards isn't just recommended it's absolutely necessary if we want our infrastructure to stay safe and functional. Most construction specs have detailed requirements about geogrid placement that engineers should follow closely. Stick to those rules and the geogrid will continue providing its intended support without letting down the whole system over years of service.

Monitoring Long-Term Soil-Geogrid Performance

Keeping an eye on how soil interacts with geogrid materials through time helps evaluate their effectiveness and keeps structures safe. These days, most experts rely on sensors along with other high-tech geotechnical equipment to get accurate readings about this relationship. Real world experience shows that when we monitor these systems for the long haul, it leads to better geogrid tech down the road. Take sensor integration as an example. When these devices are built into the system from day one, they generate all sorts of useful data. Engineers can then tweak their designs as they see what actually works in practice rather than just guessing based on theory alone.

The growing presence of Internet of Things technology opens up exciting possibilities for soil-geogrid monitoring systems. These smart devices can boost how we analyze data and help create better maintenance plans before problems even happen, which means engineers get a clearer picture of what's going on underground and can fix issues before they become major headaches. Looking ahead, IoT integration promises to transform how geogrids work in practice, making our roads, retaining walls, and other critical infrastructure much tougher against things like heavy rain, earthquakes, and shifting ground conditions over time.

Table of Contents

-

Fundamentals of Soil Strength in Foundation Engineering

- Key Factors Influencing Soil Bearing Capacity

- Challenges of Weak or Unstable Soils

- Geogrid Technology: Mechanics and Soil Interaction

- How Geogrids Enhance Soil Stability Through Interlock

- Load Distribution via Geogrid Mesh and Geo Grid Fabric

- Types of Geogrids for Foundation Reinforcement

- Uniaxial vs. Biaxial Geogrids: Structural Applications

- Triaxial Geogrids for Complex Load-Bearing Scenarios

- Geogrid Walls and Retaining Structures

- Practical Applications and Best Practices

- Case Study: Geogrid-Stabilized Highway Foundations

- Site Preparation and Geogrid Installation Guidelines

- Monitoring Long-Term Soil-Geogrid Performance