How Geogrids Enhance Slope Stability: Principles and Mechanisms

Understanding Geogrid Slope Stabilization Principles

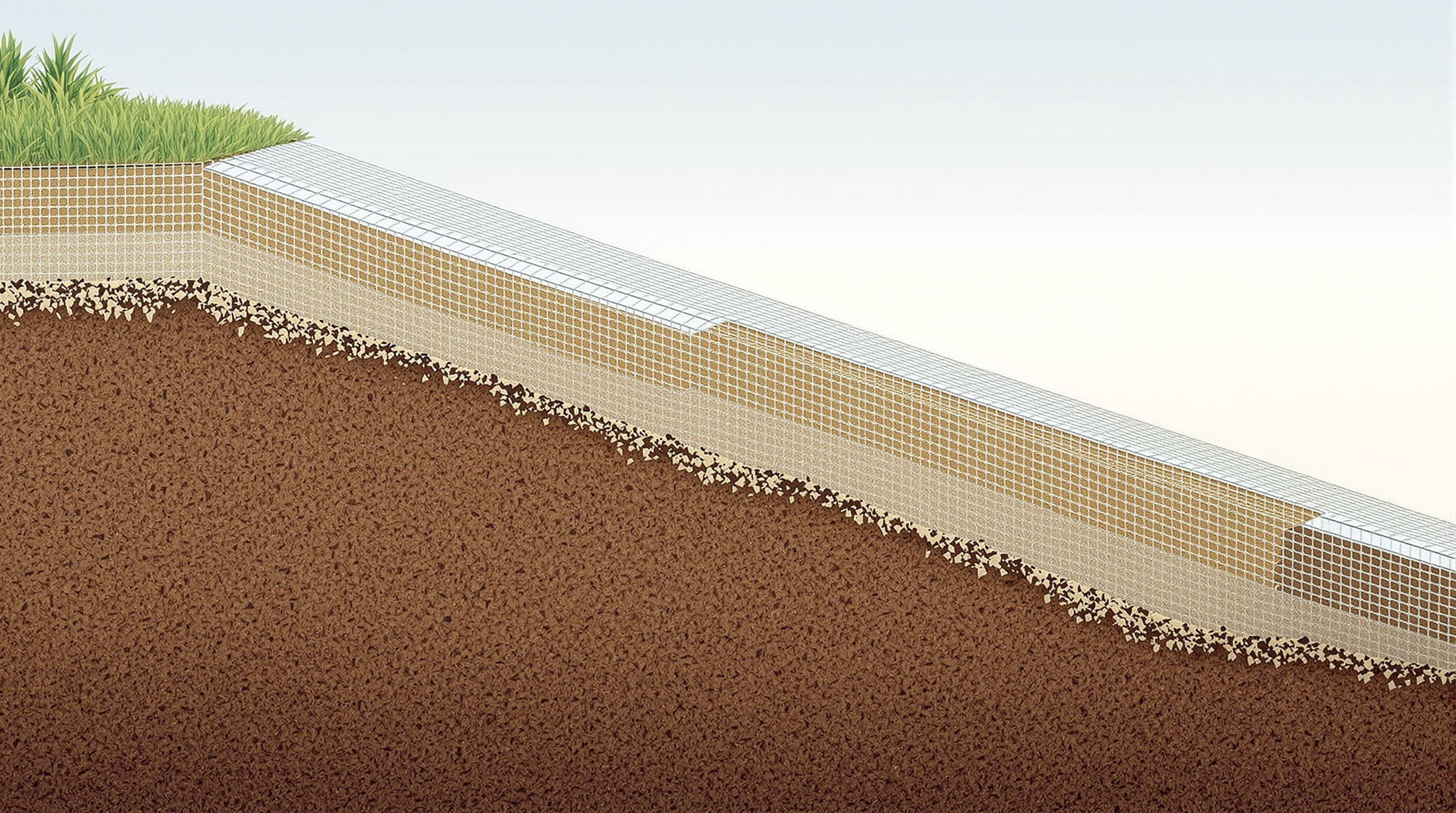

Geogrids reinforce slopes through mechanical confinement and tensile strength, leveraging polymer-based grids—typically made of HDPE or polypropylene—to form a three-dimensional matrix within soil. Unlike passive stabilization methods reliant on gravity or friction, geogrids actively redistribute stress and accommodate minor soil deformations, ensuring long-term performance in dynamic environments.

Mechanical Interlock and Tension Membrane Effect in Action

When soil particles get caught in the openings of geogrids, we see what engineers call mechanical interlocking happen. This process turns loose backfill material into something much stronger and more stable. At the same time there's another thing going on called the tension membrane effect. When a slope starts to shift or move, the geogrid stretches out and creates resistance against that movement. Studies show these two working together can boost the strength of earth structures by around 40 percent over regular unreinforced slopes according to various geotechnical models.

Soil-Geogrid Interaction and Stress Transfer Dynamics

Getting good reinforcement right means pairing the geogrid design with what kind of soil we're dealing with. There are several important considerations here. The size of the grid openings needs to work with the soil particles, along with how thick those ribs are, whether the connections between them hold up over time, and how well the materials actually grip together. When everything works as intended, stress gets distributed in two main ways. First, there's this sideways squeezing effect that stops soil particles from moving around too much. Second comes the vertical load shifting mechanism that takes pressure off weaker spots in the ground. These combined effects help prevent uneven sinking issues and keep things stable even when faced with repeated stresses from regular rain events or occasional earthquakes.

Materials and System Components in Geogrid Stabilization

Geogrid Materials (HDPE, Polypropylene): Performance and Durability

High density polyethylene and polypropylene stand out as go to materials because they hold up really well against stress and weathering over time. HDPE can handle pretty much any chemicals thrown at it between pH 2 and 13, which explains why engineers love using it around mines and along coastlines where harsh conditions are common. Polypropylene has something special going for it too when dealing with places where the ground shifts seasonally. According to Liu's work from 2019, this material keeps about 85% of its original strength even after half a century sitting outside in decent climate conditions. A study published in the Journal of Applied Polymer Science back in 2019 found something pretty impressive actually these materials cut down on sideways soil movement by nearly three quarters when compared to regular old slopes without reinforcement.

Backing Soils, Drainage Layers, and Facing Elements

Coarse, angular backfill (2–50 mm gradation) maximizes mechanical interlock with geogrid apertures. Drainage layers—using geocomposites or crushed stone—reduce hydrostatic pressure, lowering erosion risk by 60–80% in saturated conditions (FHWA 2022). Facing elements such as vegetated gabions or concrete panels prevent surface slippage while blending with natural landscapes.

Integrated System Design for Optimal Slope Reinforcement

| Component | Function | Key Specifications |

|---|---|---|

| Geogrid | Tensile reinforcement | 20–200 kN/m strength (ASTM D6637) |

| Backfill Soil | Load distribution & interlock | ¤12% fines, 95% Proctor density |

| Drainage Layer | Pore pressure reduction | ¥0.001 m/s permeability |

| Facing | Surface stabilization | 0.5–2.5 m vertical spacing |

When properly integrated, these components increase slope stability factors from below 1.0 to between 1.5 and 2.5, per ISO 17396:2018. Field data indicate such systems reduce long-term maintenance costs by 40% compared to conventional retaining walls.

Benefits and Cost-Efficiency of Geogrid Solutions

Structural Advantages in Long-Term Slope Stabilization

Geogrids significantly enhance structural resilience by reducing lateral soil movement by up to 60% compared to conventional methods (Geosynthetics Institute, 2022). Their tensile reinforcement extends infrastructure lifespan by 40–50% in high-stress environments like highway embankments and mine haul roads, where loads exceed 25 kN/m².

Cost-Efficiency and Lifecycle Savings Despite Higher Initial Investment

Although initial costs are 15–25% higher than traditional gravel fills, geogrid systems deliver 30–50% lifecycle savings through reduced maintenance and material use. A 2022 case study found that geogrid-reinforced slopes cut aggregate consumption by 35% while maintaining 98% stability over a decade—translating to $120–$180 per linear meter in long-term savings for transportation projects.

Environmental Impact and Sustainability Considerations

Geogrids reduce carbon emissions by 40% compared to concrete retaining walls by minimizing excavation and transport of virgin materials. They support sustainable practices by enabling use of local soils and reducing site disturbance. Modern HDPE geogrids have service lives of 75–100 years and are fully recyclable, aligning with circular economy goals.

Installation Best Practices and Quality Control

Installation Process for Geogrids: Step-by-Step Best Practices

Start with proper subgrade work first things first. Remove all the junk from the area, then get that soil packed down to at least 95% of Proctor density standards. Check if everything lines up with what was planned in terms of slopes and grades before moving forward. When it comes time for the geogrids, lay them across the slope direction rather than along it. Make sure those sheets overlap each other somewhere between 12 to 18 inches so there aren't any weak spots where they meet. To hold everything in place initially, install those galvanized J-hooks every three feet or so along the front edge. For backfilling, go right away with angular aggregate that's been properly graded. Work in layers about 8 to 12 inches thick, making sure each layer gets compacted down to around 90-95% density using those vibratory rollers. Just remember not to turn heavy machinery directly over exposed grid sections since this can tear things apart pretty easily during operation.

Common Pitfalls and Quality Control Measures

Three common installation errors threaten performance:

| Pitfall | Quality Control Measure | Standard Reference |

|---|---|---|

| Inadequate surface prep | Laser grading verification (±0.5° tolerance) | ASTM D5876 |

| Poor overlap alignment | RFID-tagged geogrid tracking | ISO 10318-4:2023 |

| Insufficient compaction | Nuclear density gauge testing (¥90% density) | ASTM D6938 |

Post-installation verification should include ASTM D6638 wide-width strip tests to confirm tensile strength retention (>80%). For slopes steeper than 45°, embed wireless strain sensors at 15-foot intervals to monitor real-time tension distribution.

Real-World Applications and Industry Adoption Trends

Applications in Highway Embankments, Mining, and Coastal Protection

Geogrids are widely adopted across infrastructure sectors for slope stabilization:

- Highway embankments: Over 72% of U.S. state DOTs require geogrid reinforcement for cut-and-fill slopes exceeding 45°

- Mining operations: Prevent waste pile failures and stabilize haul roads, saving an average of $740,000 annually per site (Ponemon 2023)

- Coastal protection: Salt-resistant polymer grids protect seawalls from erosion while supporting vegetation regrowth

Case Study: Reinforced Slope Failure Prevention on I-70 Corridor

A 2022 Colorado DOT project along the mountainous I-70 corridor used high-strength polyester geogrids to increase slope safety factors from 1.3 to 1.8. The solution reduced excavation volume by 40% compared to traditional retaining walls and incorporated enhanced drainage to withstand freeze-thaw cycles, improving long-term durability.

Trend: Increasing Adoption in Post-Mining Land Reclamation

Geogrid reinforcement is now mandated in 31 U.S. states for reclaiming former mining sites, driven by:

| Factor | Impact |

|---|---|

| Accelerated timelines | 50% faster vegetative cover establishment |

| Cost efficiency | $18–$22/sq.yd savings versus concrete alternatives |

| Regulatory compliance | Meets SMCRA 2024 stability thresholds |

Future Outlook: Expanding Use in Climate-Resilient Infrastructure

With 68% of civil engineers prioritizing erosion-resistant designs (ASCE 2025), geogrid adoption is projected to grow 14% annually through 2030. Growth will be strongest in landslide-prone corridors, flood mitigation systems, and rehabilitation of wildfire-affected terrain, where rapid, durable stabilization is critical.

Frequently Asked Questions

What are geogrids and what do they do?

Geogrids are polymer-based grids used to reinforce soil. They enhance slope stability by providing mechanical confinement and tensile strength, redistributing stress within the soil.

Why are HDPE and polypropylene commonly used materials for geogrids?

HDPE and polypropylene are favored for their durability and chemical resistance. HDPE, in particular, withstands harsh environmental conditions, while polypropylene retains strength over long periods.

What is the mechanical interlock and tension membrane effect?

The mechanical interlock occurs when soil particles get caught in geogrid openings, strengthening the material. The tension membrane effect provides resistance when a slope shifts, working together to improve stability.

How cost-effective are geogrid solutions compared to traditional methods?

Although initial costs are higher, geogrid solutions offer significant lifecycle savings due to reduced maintenance and material usage. They are environmentally friendly and last for many years.