Understanding Geosynthetics and Their Types

Geogrids and Biaxial Geogrid Mesh

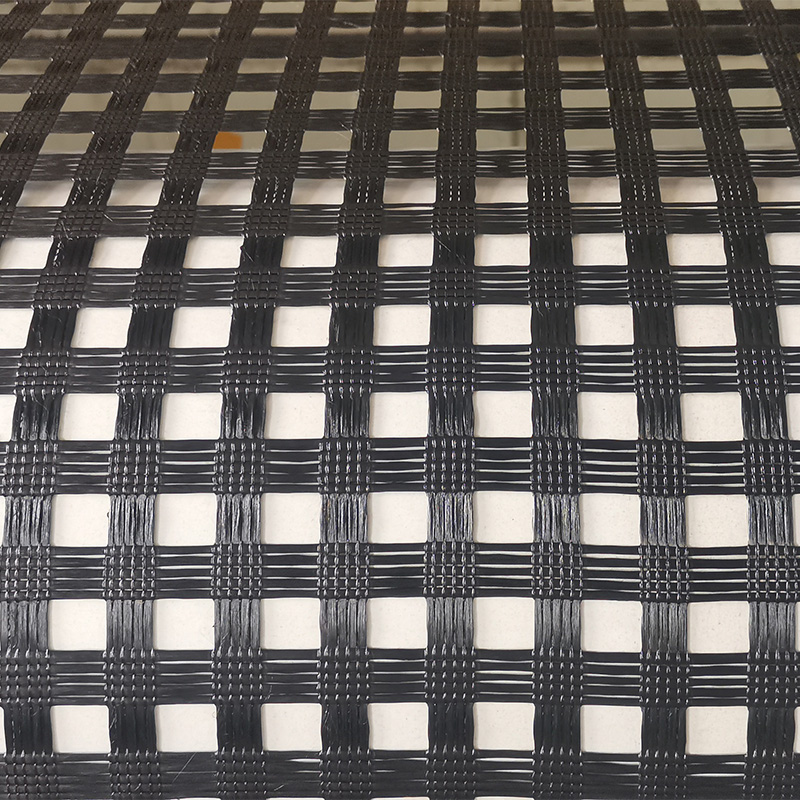

In civil engineering work, geogrids play a pretty important role as reinforcing materials across many different projects. These grid-like structures basically help strengthen soil mechanics through better structural support, more even load spreading, and creating stronger interactions between the grid and surrounding earth. There are mainly two kinds of geogrids out there - uniaxial and biaxial. When engineers need reinforcement along just one axis, they'll typically go with uniaxial grids, which show up a lot in things like building retaining walls. Biaxial options handle stresses from multiple directions though, making them ideal for bigger infrastructure jobs like stabilizing roads or railway beds where forces come at angles. The choice between these types really depends on what specific project requirements look like on site.

Biaxial geogrid mesh finds real application in earth reinforcement work all over the construction field. Take road embankments for example these grids help keep slopes stable when the ground wants to shift around. What makes this technology so useful is how it cuts down on soil deformation problems that plague many earthworks projects. When installed properly, geogrids spread out the weight more evenly across the surface area while also creating better bonding between individual soil grains and the reinforcing material itself. This reduces unwanted sideways movement in the dirt layers beneath roads and buildings. Field tests have shown results where soil deformation dropped as much as half compared to traditional methods. That kind of performance makes geogrid solutions particularly attractive for sites sitting on poor quality soils that just cant hold up under normal loads without extra support.

Geotextiles and Geo Mesh Applications

In construction and environmental engineering projects, geotextiles serve multiple purposes including filtration, separation, and reinforcing structures. Made from permeable materials, these fabrics help enhance soil properties while allowing water to pass through, which stops different soil layers from getting mixed up. When it comes to types, there's basically two main categories: woven and non-woven varieties. The woven kind tends to handle heavy loads better, so they're commonly found under roads and supporting retaining walls where strength matters most. On the other hand, non-woven geotextiles excel at letting water drain properly and controlling erosion issues, making them ideal choices for underground drainage systems and areas prone to soil loss problems.

We see geotextiles at work all over our roads, helping keep them intact while fighting off erosion that would otherwise eat away at the surface. These materials basically act as a protective layer between different soil layers. Then there's something called geosynthetic membranes which serve similar purposes but specifically handle water management issues. They stop harmful substances from seeping into nearby environments, kind of like an invisible shield against pollution. As researchers continue developing better materials, we might start seeing some pretty interesting changes in how we build things. Some experts believe these improvements could make construction sites cleaner places overall, though it remains to be seen exactly how fast this will happen across different regions around the world.

Mechanisms of Soil Reinforcement with Geosynthetics

Tensile Strength and Load Distribution

When it comes to reinforcing soil, tensile strength plays a major role in determining how stable the ground will be. Basically, tensile strength measures how much force a material can withstand before snapping apart, which matters a lot for those synthetic materials engineers put in the ground. The connection between these materials and load distribution works pretty straightforwardly actually. Materials with greater tensile capacity spread out weight better across the entire soil structure, making everything more stable overall. Getting good results from this property requires careful installation though. Take road construction as an example. Contractors often lay down geosynthetic fabrics beneath pavement layers so they can handle all that traffic without sinking or cracking. Without proper placement during construction, even the strongest materials won't perform as expected when subjected to real world stresses over time.

When looking at different materials, the tensile strength numbers can be all over the map between various geosynthetics. Take uniaxial geogrids for example they generally have higher tensile strength compared to their biaxial counterparts, which makes them good choice when we need support primarily in just one direction. Biaxial geogrids tell a different story though. These bad boys offer pretty much equal strength in both directions, so engineers tend to reach for them when reinforcing bases or foundations where forces come from multiple angles. We see this play out in actual construction sites too. Retaining walls and highway embankments benefit greatly from proper load distribution provided by these materials, cutting down on problems like soil shifting or structural collapse. Understanding what kind of tensile strength we get from each material isn't just theory stuff it actually matters a lot when trying to make sure our soil reinforcement projects hold up under pressure.

Friction and Interlocking Mechanisms

The friction between soil particles and geosynthetic materials is really important when it comes to reinforcing soil structures. This friction helps keep everything stable, but what makes it work depends on things like how rough or smooth the geosynthetic surface is and what kind of soil we're dealing with. Take a textured geogrid for example it tends to grip soil particles better than smoother ones, which means the whole system stays more stable under stress. There's also something called an interlocking effect where actual soil grains get caught in the spaces between the geogrids. This creates extra mechanical strength that just isn't there with plain old flat surfaces.

Real world testing shows just how much stronger soils can become when geosynthetics are used properly. Take road embankments for example where engineers have found that adding these synthetic layers actually boosts the ground's ability to hold weight through friction between particles and mechanical locking effects. The field is moving fast though, with researchers currently experimenting with different fabric weaves and coatings that might make these materials work even better over time. What we're seeing now is already changing how civil engineers approach site preparation, giving them tools to tackle tricky ground conditions without relying solely on traditional methods that often require massive amounts of earthmoving equipment and additional support structures.

Key Applications in Long-Term Soil Stability

Reinforcing Retaining Walls and Steep Slopes

Geosynthetics are essential when it comes to reinforcing retaining walls and steep slopes because they stop erosion and make the whole structure stronger. Using geotextiles can cut down on construction costs for retaining walls by around half compared to older techniques, plus they offer better support on unstable ground. We've seen this work well across many different locations around the globe. Take steep slopes for instance - adding geosynthetics there really boosts stability by keeping soil from slipping away and spreading out weight more evenly. This makes all the difference in tricky landscapes and changing weather conditions where conventional building approaches just don't hold up over time. Research indicates that structures reinforced with geosynthetics last longer and handle environmental stress much better, which means they represent a wise investment from both financial and ecological standpoints.

Stabilizing Foundations and Embankments

Stable foundations matter a lot in construction work, especially when dealing with soft ground or shaky soil conditions. That's where geosynthetics come into play as a solid fix for these problems. Traditional approaches usually eat up tons of materials and manpower, but geosynthetics strengthen the soil tension and improve stability while requiring far less effort overall. Take road embankments and big building foundations for example we see time and again how these synthetic materials spread out weight better and stop the soil from shifting around so much. Projects using reinforced geosynthetic layers report real gains in how much weight they can hold up. Some studies even show settlements dropping by around 30% and better resistance during earthquakes. This stuff really shines in major construction jobs where keeping the base intact is absolutely essential. Going with geosynthetics means getting better results, saving money on materials, and leaving a lighter footprint on the environment too.

Enhancing Shear Strength Through Geosynthetic Integration

Laboratory Testing and Performance Metrics

Getting a handle on the shear strength numbers for geosynthetics matters a lot when they're being used in real world construction scenarios. Lab work remains key here since it gives engineers actual data points about how these synthetic materials actually hold up structurally. Most labs run either pull out tests or direct shear tests to see exactly how the geosynthetic interacts with surrounding soil layers. These tests measure important factors like maximum load capacity before failure occurs and how well the material resists sliding under pressure. For contractors looking at long term durability, these performance stats become critical numbers to watch when deciding if a particular geosynthetic solution will stand up to the job requirements over time.

Lab tests over the years keep showing how geogrids and geo mesh really stand out when it comes to boosting soil shear strength. Take biaxial geogrids for example they spread loads much better and cut down on sideways movement, which means structures stay stable longer. Most contractors follow standards set by groups like BSI to make sure their testing methods are solid. What these tests actually do is confirm that geosynthetics work well in practice, not just theory. Engineers find them particularly useful because they can be applied to all sorts of soils and weather conditions. This makes a big difference in construction projects where getting the design right matters for both safety and budget.

Advantages of Modern Geosynthetic Solutions

Durability in Harsh Environmental Conditions

Geosynthetic materials have proven remarkably tough when exposed to brutal environmental conditions. They hold up against temperature extremes and can handle all sorts of wet soil situations without compromising the structures they're part of. The Geosynthetic Institute did some testing recently showing how HDPE geomembranes keep their strength across a wide temperature range, from almost freezing right up to blistering heat. For engineers working on infrastructure in regions where weather goes wild, this kind of reliability makes all the difference. Manufacturers continue improving these materials through better compositions and smarter production methods, which means geosynthetics just keep getting stronger over time. That's why so many construction professionals turn to them whenever dealing with tough site conditions.

Cost-Effectiveness in Large-Scale Projects

Geosynthetic materials tend to be much more budget friendly than traditional alternatives when it comes to big construction jobs. Contractors love these synthetic fabrics because they need less upkeep and last longer in the field. Take road building for example most highway departments now specify geogrid reinforcement systems which cut down on both time spent maintaining roads and money wasted fixing potholes later on. The construction industry has seen a real shift toward using these materials lately as companies look for ways to save cash without sacrificing quality. What's interesting is how many engineers are starting to see geosynthetics not just as cost savers but actually as smart investments that pay off over decades rather than just months. This dual benefit of immediate savings plus long term value makes sense especially when looking at infrastructure that needs to stand up for generations.

Table of Contents

-

Understanding Geosynthetics and Their Types

- Geogrids and Biaxial Geogrid Mesh

- Geotextiles and Geo Mesh Applications

- Mechanisms of Soil Reinforcement with Geosynthetics

- Tensile Strength and Load Distribution

- Friction and Interlocking Mechanisms

- Key Applications in Long-Term Soil Stability

- Reinforcing Retaining Walls and Steep Slopes

- Stabilizing Foundations and Embankments

- Enhancing Shear Strength Through Geosynthetic Integration

- Laboratory Testing and Performance Metrics

- Advantages of Modern Geosynthetic Solutions

- Durability in Harsh Environmental Conditions

- Cost-Effectiveness in Large-Scale Projects