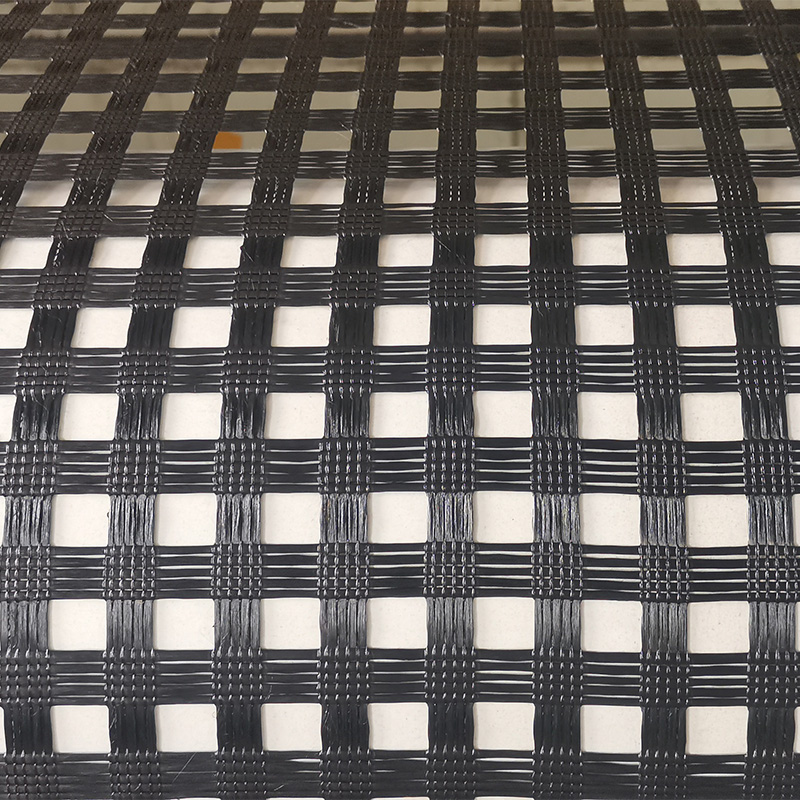

Glass fiber geogrid, just like fiberglass geogrid, is made of high-strength glass fibers, features warp-knitted construction with a coating that enhances its mechanical properties and protects against environmental degradation. It possesses enduring tensile strength and low elongation alongside superb resistance to chemicals and UV radiation. In road and pavement applications, glass fiber geogrid aids in reinforcing asphalt slabs by mitigating reflective cracking and enhancing fatigue life. It also effectively reinforces in soil stabilization projects by increasing soil shear strength and load-bearing capacity.

Copyright © 2025 by Shandong Sunshine New Material Technology Co.,Ltd - Privacy Policy